Attention! The working edge of the stuffing box is very sensitive, and in no case should it be bent. It is forbidden to touch the working edge with your hands.

The stuffing box can only be replaced as an assembly with a cover. The seal is an integral part of the stuffing box and should not be replaced separately.

Check the correct position of the support sleeve, which is included in the scope of delivery. If the stuffing box has been stored without a support sleeve for more than six months, then it is forbidden to install it. The follower sleeve remains in the stuffing box and is used as a sliding sleeve during the installation described below.

Previously Released Device «11.2.390» use is prohibited. When installing the oil seal as a sliding sleeve, use only the support sleeve supplied.

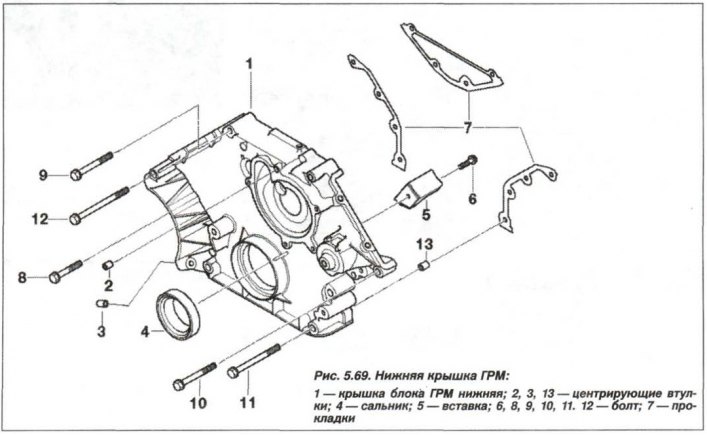

Check centering sleeves (12, see fig. 5.69) for damage and correct installation. Sealing surfaces must be clean and free from grease.

Apply to corner joints (arrows) the plane of the connector with an oil sump is a layer of sealant of the Drei Bond 1209 type. Lightly lubricate with engine oil the landing surface of the crankshaft and the working edges of the oil seal, do not touch the edges with your hands.

Install cover (1, fig. 5.74) with support sleeve (2) oil seal on the crankshaft, avoiding its distortions, and carefully slide it on.

Replace sealing washers under bolts (1 and 2, see fig. 5.73). Insert and tighten bolts first (1) and then bolts (2) fixing the seal cover. Tighten bolts first (1) and then bolts (2) fixing the stuffing box cover with a torque of 12 Nm (1.2 kgf·m).