Attention!

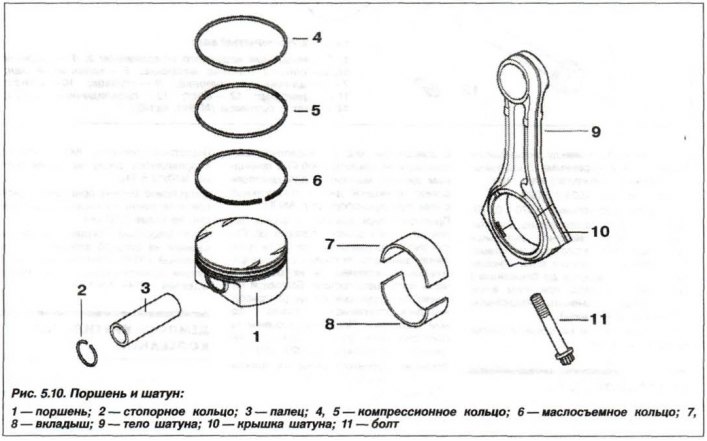

- Pistons and piston pins are paired and cannot be dismantled.

- The crankshaft journal bearing cap is machined together with the connecting rod and must not be dismantled. There is a marking on the cylinders and direction.

- The connecting rod and bearing cap markings must be on the same side and match as a pair.

- Install pistons, connecting rods and bearing shells in the same place and in the same position.

- When installing the pistons in the cylinders, in order to avoid breakage of the piston rings, do not apply significant force.

- The piston pin must be pushed through the bushing by finger pressure and have no visible play with it.

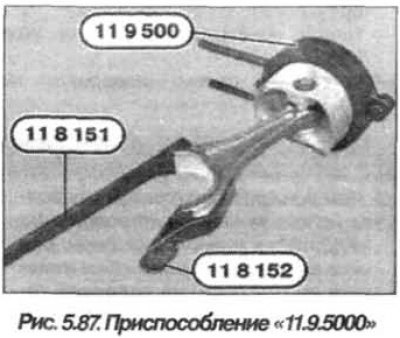

The pistons must be replaced in the following order. Prepare fixtures «00.9.120», «11.8.141», «11.8.151», «11.8.152» And «11.9.500».

Remove the engine and install it on the assembly stand. Remove both cylinder heads and oil sump.

Note. The sequence of operations for removal and installation is different.

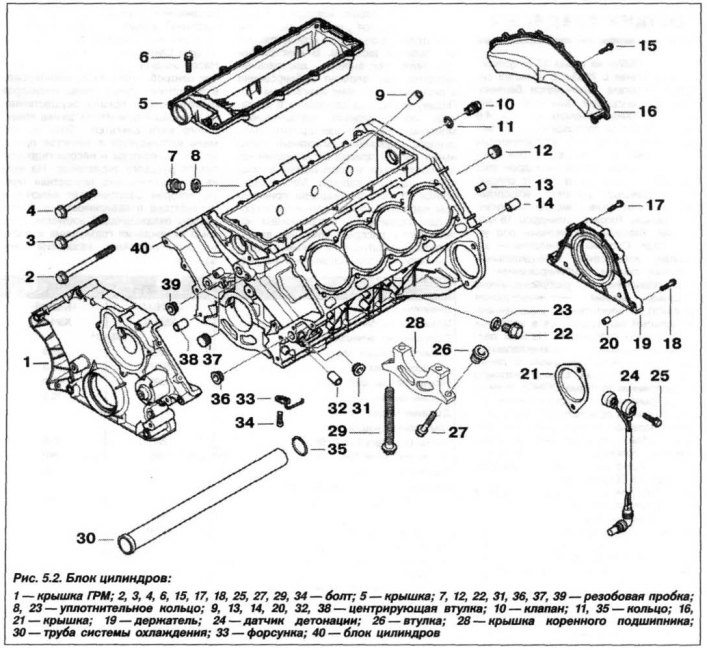

Remove oil pump. If there is a strong oil deposit on the firing zone, carefully remove it from the cylinder walls. In the lower part of the cylinder block, between the beds of main bearings, nozzles are installed (33, see fig. 5.2) for piston cooling. In order not to damage the injectors, it is recommended to unscrew the screws and remove them.

Loosen the bolts (11, see fig. 5.10) and remove covers (10) connecting rod bearings, put them in order.

Reinstall the connecting rod bolts «11.8.151» And «11.8.152» (pic. 5.84).

Move the connecting rod with the piston towards the cylinder head, remove and remove the installed tools. Remove retaining ring (2, see fig. 5.10) and press out the piston pin (3).

Check the technical condition of the pistons, pins, connecting rods, bearing shells and piston rings, replace them if necessary.

Note. The connecting rods can be replaced separately.

Before installation, measure the nominal clearance between the piston and the bore in the cylinder block, for which:

- measure the piston diameter with a micrometer «A», 11.0 mm for the N62B36 engine or 18.0 mm for the N62B44 engine, from the lower edge of the skirt in the plane, at an angle of 90°to the axis of the piston pin, and offset by 90°in the horizontal plane from the axis under the piston pin.

- measure the diameter of the cylinder mirror in three planes with a micrometer (top, middle and bottom) and calculate the average. Cylinder bore diameter, nominal, for the N62B36 engine - 84.000+0.014 mm, for the N62B44 engine - 92.000+0.014 mm.

- subtract the piston diameter from the average cylinder diameter;

- the resulting value of the nominal clearance during installation should be in the range of 0.001–0.044 mm, the working clearance should be in the range of 0.026–0.073 mm, the maximum allowable value, as a criterion for the necessary repair when parts are worn, is 0.10 mm.

The piston pin should be pushed through the connecting rod bushing with finger pressure and have no visible play or binding.

The pistons of cylinders 1-8 are identical.

Attention! The connecting rods for cylinders 1-4 and 5-8 are installed differently.

Cylinders 1–4

Assemble the connecting rod with the piston pin in the piston so that the flat side of the connecting rod (bottom arrow) pointing backwards and the arrow on the piston facing forward (pic. 5.85).

Cylinders 5–8

Assemble the connecting rod with the piston pin in the piston so that the flat side of the connecting rod (bottom arrow) was facing forward and the arrow on the piston was facing forward (pic. 5.86).

Install the piston pin circlip in such a way that its lock is located against the recess in the piston.

Install fixtures «11.8.151» And «11.8.152» in place of the connecting rod bolts.

Lightly coat pistons and piston rings with engine oil. Align the piston rings so that their locks are located at approximately 120°, while they should not be located above the piston bosses.

With the N62B44 engine, compress the piston rings with a tool «11.9.500» (pic. 5.87), while holding them compressed, install the pistons so that «arrow» on the head (bottom) piston pointed towards the timing drive. For N62B36 engine, use tool «11.8.141».

By pressing the fingers of the hand, insert the piston into the cylinder of the block, do not apply significant force, because of the danger of breakage of the piston rings.

Align crankshaft journal and connecting rod head (see fig. 4.81) and remove fixtures «11.8.151» And «11.8.152».

Replace the connecting rod bearing shells and lubricate them with engine oil.

Install the bearing cover in this way (pic. 5.88), to match on one side the letters of their selection in a pair («VU»).

Insert new, clean connecting rod bolts lightly lubricated with engine oil. Using fixture «00.9.120» (torque wrench with goniometer), tighten both bolts in three parallel steps on each bolt:

- 1st step - tighten with a torque of 5.0 Nm (0.5 kgf·m);

- 2nd step - tighten with a torque of 20 Nm (2.0 kgf·m);

- 3rd trick - tighten by an angle of 70°.

Proceed with assembling the engine in the reverse order, at the same time it is necessary to replace the screws for fastening the piston cooling nozzles, the threaded part of the screws should be covered with an anti-loosening agent.