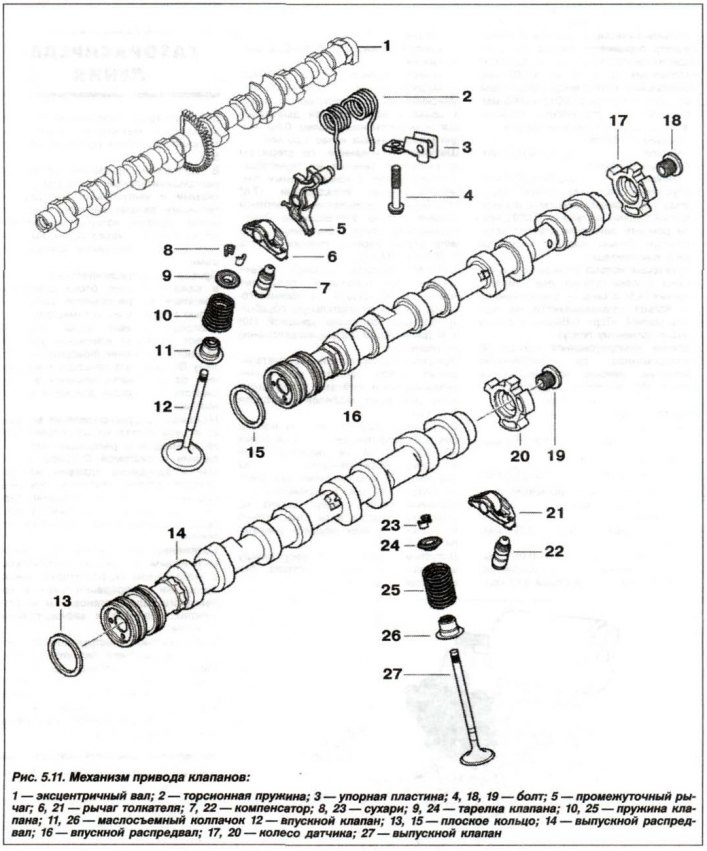

Clean all bearing beds and intake camshaft lobes and lubricate them with engine oil. Inlet camshaft (16, see fig. 5.11) has a groove, and the wheel (17) sensor of its position - a protrusion for their mutual fixation.

Put on the wheel (17) sensor and align it with the groove in the camshaft. Insert and tighten bolt (18, M16x1.5) torque 30.0 Nm (3.0 kgf·m). Insert rings (13) rectangular section, the installation should start from the far ring. Be extremely careful, rings break easily. Carefully spread the ends of the ring and install it into the groove. Press the end of the ring into the groove, and on the other hand, hook it with a retainer.

Insert camshaft (16) intake valves so that the cams of the 5th cylinder point up.

Make sure the earbuds (1, fig. 5.104) bearings of the eccentric shaft are fixed in the support bridge.

Note. Insert (1) bearing fits into a groove in the bearing cap.

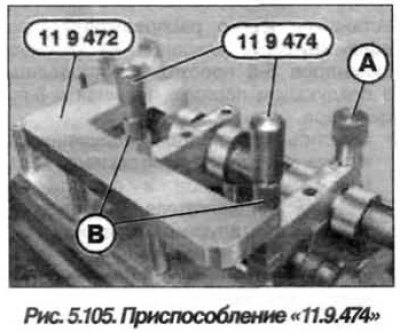

Check centering sleeves for damage and correct installation. Install bearing caps «RE2–RE5», fixture «11.9.473» and fix the support bridge and bearing cover with a nut. Install fixture «11.9.472» and expose the bearing bed of the intake camshaft.

Install centering sleeves (fixture «11.9.475»), and set the fixture «11.9.472» in relation to bearing caps 2 and 3. Install tools «11.9.474» (pic. 5.105) and roll them up until snug.

Note. fixtures «11.9.472», «11.9.474» And «11.9.475» remain installed until all torsion springs and intermediate arms are installed.

Installation of intermediate levers and torsion springs of cylinders 5-7 is similar to cylinder 8.

Install fixtures «11.9.400» on one end of the torsion spring of the 8th cylinder and rest the torsion spring on the cylinder head. Insert bolt (M7) (1, see fig. 5.101) and tighten it.

Lubricate all sliding surfaces of intermediate levers with engine oil. Raise one end of the torsion spring with the tool «11.9.480» and remove the device «11.9.490». Hold one end of the torsion spring up and install the intermediate lever from above. Insert the first end of the torsion spring into the guide on the intermediate arm.

Raise the second end of the torsion spring using the tool «11.9.480» and remove the device «11.9.490». Hold the other end of the torsion spring up (see fig. 5.101), install the intermediate lever from above. Insert the other end of the torsion spring into the guide on the intermediate arm.

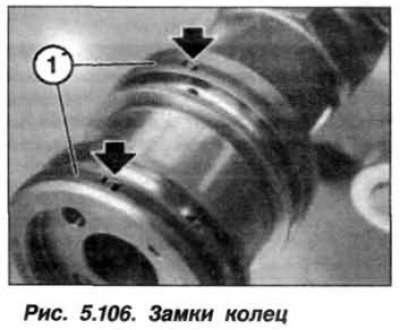

Install eccentric shaft position sensor and remove tools «11.9.474», «11.9.475». Make sure the ends of the rings (1, fig. 5.106) pointing up and their locks (arrows) snapped into place.

Attention! The pusher arms are easy to move when installing the support bridge. Do not turn over the support bar.

Make sure the lever (1) the pusher is fixed, as shown in Figure 5.107, on the elements of the hydraulic valve clearance compensation system and on their valves. Align levers (1) valve lifters. Remove tool «11.9.473» and fixture «11.9.470» from the base jumper.

Install the jumper (1, fig. 5.97) from top to bottom and carefully bring it into contact with the cylinder head.

Set nuts (M7, arrows) and wrap them by hand, until they touch the support jumper.

Attention! Make sure that the intermediate levers and pusher levers are in place and have not slipped.

Tighten nuts (M7) from the middle to the edges, torque 14 Nm (1.4 kgf·m). Install the bearing cover «RE1» so that the marking is readable from the intake side. Set nuts (M7, arrows) and tighten them to 14 Nm (1.4 kgf·m).

Turn the intake camshaft in the direction of rotation so that the cam of the 5th cylinder takes an inclined upper position, as shown in Figure 5.108 (arrow).

Install left intake and exhaust VANOS control units. Screw in spark plugs for cylinders 5-8. Install the left cylinder head cover and ignition coils for cylinders 5-8. Install the left eccentric shaft drive motor and assemble the motor.