Inserts of the radical bearing of a cranked shaft

The replacement of the crankshaft bearing shells must be carried out in the following order. Prepare fixtures «00.2.590», «00.9.120» And «11.2.110». The engine is disassembled, the crankshaft and cylinder head are removed. Removed the front timing block, rear oil seal and oil pump.

Attention!

- When replacing liners in the crankcase, install only liners with a yellow mark.

- To check the radial clearance in the main bearings, use the old main bearing cap bolts.

- When checking the clearance in the bearings, do not allow the crankshaft or connecting rod to turn.

Pay attention to the label (yellow, green or white) and crankshaft oversize mark. Block bearing shells have the same markings.

Install the thrust bearing shell into the block, while paying attention to the repair size of the main journals. In accordance with the diameter of the main journals, the crankshaft has a yellow, green or white marking.

The bearing cap classification is marked on the crankshaft with a yellow, green or white marking. The #6 main bearing cap is a thrust bearing.

Check the radial clearance of the crankshaft main bearings using the plastic gauge wire type «Plastigage PG1», placed on the oil-free crankshaft journal. Technology similar to motors «M54» .. «N62».

The radial clearance should be between 0.020 - 0.055 mm for the thrust bearing and 0.019 - 0.052 mm for all other bearings.

If necessary, to correct the value of the radial clearance in the bearing, it is necessary to use new bearing shells or shells with a different color marking. The diagram of applicability of liners is shown in Figure 6.58.

Install the main bearing cap bolts in the following order:

- tighten all the bolts of the main bearing caps from the middle to the edges to a torque of 22 Nm (2.0 kgf·m);

- unscrew the bolts securing the main bearing cap No. 6;

- tap the rear and front ends of the crankshaft with a plastic-headed hammer to expose the thrust bearing;

- tighten the main bearing cap bolts No. 6 to 22 Nm (2.2 kgf·m);

- tighten all the bolts of the main bearing caps from the middle to the edges at an angle of 90°, for which use the tools «11.2.110» or «00.9.120».

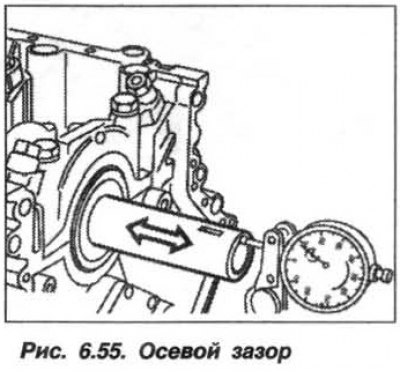

Check crankshaft axial clearance (see fig. 6.55), the nominal value of which should be in the range of 0.080–0.234 mm. If necessary, replace thrust bearing shells, crankshaft and cylinder block.

Assemble the engine.

Connecting rod bearing shells

Attention! Connecting rod bearings are different from connecting rod cap bearings. Pay attention to the marking of the crankshaft (repair dimensions).

Checking the value of the radial clearance and replacing the crankshaft connecting rod bearing shells is carried out in the same way as replacing the main bearing shells, taking into account the following.

Prepare fixtures «00.2.590», «00.9.120» And «11.2.110» and remove all pistons. The connecting rod caps and the connecting rod itself are paired and cannot be dismantled.

The connecting rod cover is fitted with a standard insert of the Low version, red. A wear-resistant insert with the marking is installed in the lower head of the connecting rod «S» versions «High», blue. Insert one red and one blue bushing into each connecting rod, regardless of the color marking of the connecting rod rod (arrows, fig. 6.59).

Install the pistons in the cylinder block and check the radial clearance between the liners and necks (pic. 6.60), which should be within 0.019 - 0.052 mm for all connecting rod bearings. When checking the clearance, use the old connecting rod cap bolts. When checking, set the piston to the BDC position.

Check the gap in the same way as engines «M54» .. «N62», using fixture «00.2.590» (Plastigage PG-1).

Bolt tightening order (old, just for checking) connecting rod bearing cap as follows:

- tighten bolts to 5.0 Nm (0.5 kgf·m);

- tighten bolts to 20.0 Nm (2.0 kgf·m);

- tighten the bolts by 70°using the tool «00.9.120».

Attention! When tightening the bolts, do not allow the connecting rod or crankshaft to turn.

If necessary, to correct the value of the radial clearance in the bearing, use new bearing shells or shells with a different color coding. The diagram of applicability of liners is shown in Figure 6.61.

Install the connecting rod caps. Wash the new bolts of the lower covers of the connecting rods of the old release in kerosene and lubricate with engine oil. New release bolts have an indelible coating. Tighten bolts as above. Assemble the engine.