Attention! Do not lubricate the oil pan seal with oil.

Replacing the pan gasket (oil sump) engine must be carried out in the following order. Prepare fixtures «00.0.200»; «00.0.201»; «00.0.202»; «00.0.203»; «00.0.204» And «00.0.208». Remove the soundproof cover and lock the hood in position for maintenance.

Remove the radiator shroud and engine accessory guards. Drain the engine oil and lower the front axle beam.

Assemble fixture «00.0.200» with fixtures «00.0.201»; «00.0.202»; «00.0.203»; «00.0.204»; «00.0.208» and install it on the engine compartment.

Fasten fixture «11.0.020» in the front and rear engine lifting eyes and in the «00.0.200».

Attention! Due to the risk of damage, the racks (1) fixtures «00.0.208» must rest on the bolts in both fenders.

Remove the screw (1, see fig. 6.34) on the left and right engine mounts.

Using fixture «00.0.200», raise the engine, no more than 20–25 mm (pic. 6.45).

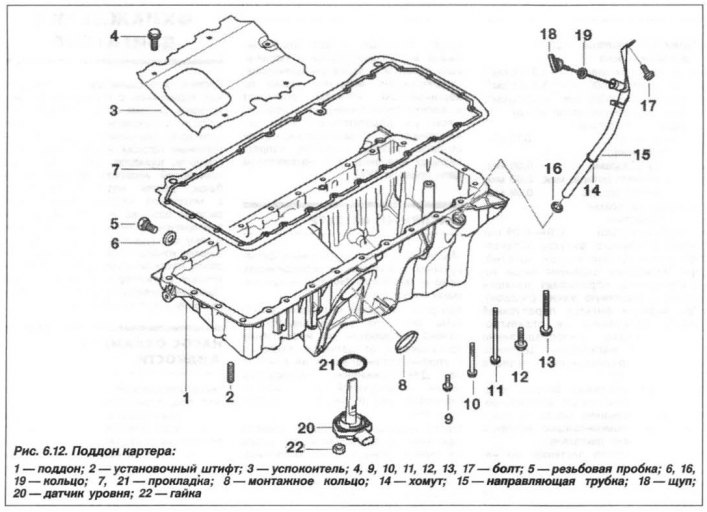

Loosen the screw and remove the oil dipstick tube. Disconnect loop (4) from the oil level sensor. Mark the oil pan mounting bolts, as they have different diameters.

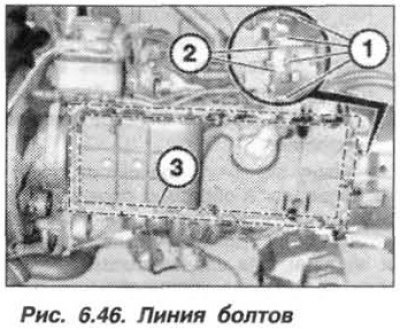

Remove screws (1, fig. 6.46) and bolts (2). Loosen the bolts along the line (3).

Remove oil sump downwards and seal (7, see fig. 6.12). Clean sealing surfaces of seal residues.

Apply liquid sealant «Drei-Bond-1209» in places (1, fig. 6.47), on the joint surface, on the oil sump and on the block itself. Apply sealant in a thin layer.

Install the oil pan with a new gasket. Tighten all bolts in a criss-cross pattern from the middle to the outside. Bolts M6 (10.9) tighten torque 12 Nm (1.2 kgf·m), M8 bolts (8.8) tighten torque 22 Nm (2.2 kgf·m). Assemble the engine.