Check the technical condition of the pistons, pins, connecting rods, bearing shells and piston rings, replace them if necessary.

Before installation, measure the nominal clearance between the piston and the bore in the cylinder block, for which:

- measure the piston diameter with a micrometer at a distance «A» – 12 mm, from the lower edge of the skirt in a plane at an angle of 90°to the axis of the piston pin, measure the diameter of the cylinder face in three planes with a micrometer (top, middle and bottom) and calculate the average;

- subtract the piston diameter from the average cylinder diameter;

- the resulting value of the nominal gap should be in the range of 0.041–0.077 mm, the maximum allowable value, as a criterion for the necessary repair when parts are worn, is 0.15 mm.

Wash new connecting rod bolts, lubricate with engine oil, insert and, using tools «00.9.120» or «11.2.110» – a torque wrench with a goniometer, tighten the bolts in three parallel steps on each bolt:

- 1st step tighten to 5.0 Nm (0.5 kgf·m);

- 2nd step tighten to 20 Nm (2.0 kgf·m);

- Tighten the 3rd step by 70°.

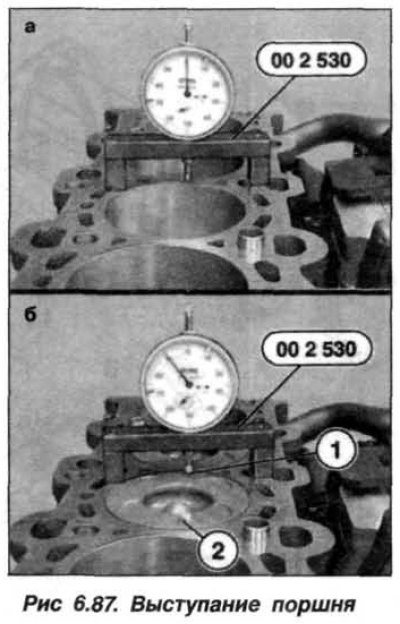

After carrying out work that causes changes in the protrusion of the piston crown above the mating surface of the cylinder block, it is necessary to re-determine the thickness of the sealing gasket in the following order:

- install a dial indicator with a measuring block, a tool «00.2.530» (pic. 6.87, a) on the cleaned surface of the cylinder block and set the indicator to zero;

- set the piston to a position close to TDC;

- install fixture «00.2.530» on the cleaned piston surface at two measuring points (1 and 2, fig. 6.87, b), turning the crankshaft by the vibration damper bolt, take the maximum reading of the indicator at the highest point of piston lift;

- draw and record the protrusion of the piston head at points (1 and 2) for all six pistons;

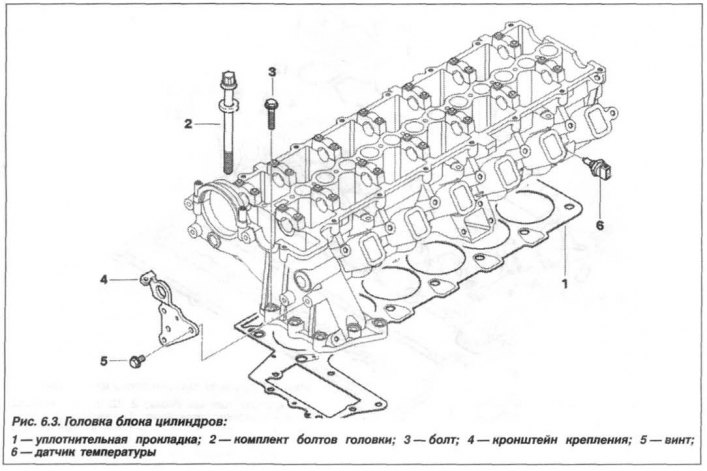

- the largest value, out of 12 measurements, determines the thickness of the gasket (1, see, fig. 6.3) cylinder heads;

- with a piston protrusion of 0.92–1.03 mm, install a gasket with two holes, with a piston protrusion of more than 1.03 mm, install a gasket with three holes.

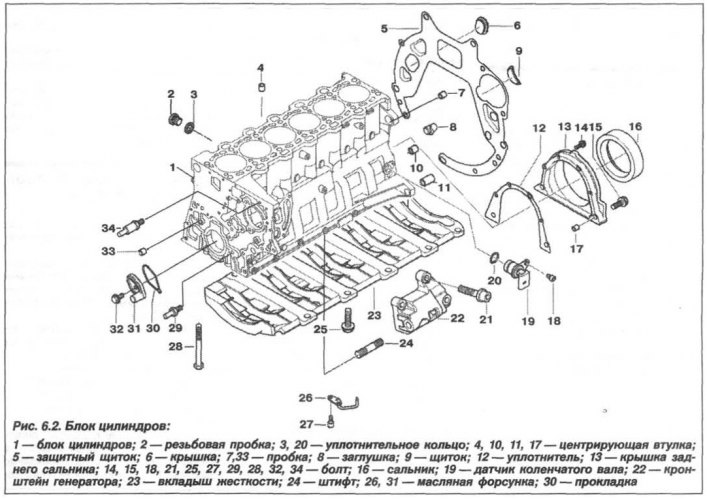

Install stiffener (23, see fig. 6.2) according to its marking, the arrow is directed towards the timing drive.