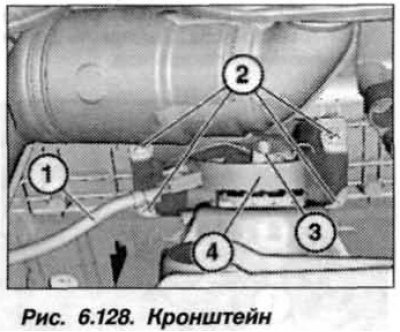

Disconnect jumper (1, fig. 6.128) connections with «weight» from the engine mount bracket. Remove bolts (2) and unscrew the nut (3) bracket mounting. Detach right engine mount bracket from cylinder block and remove. Installation of the bracket for the right engine mount should be carried out in the reverse order, if necessary. Clean the contact surfaces to ensure a secure connection between the jumper and «weight».

bolts (2) M8 (8.8) fastening the bracket to the engine tighten the torque 19.0 Nm (1.90 kgf·m). Nut (3) M10 (10.9) tighten the bracket to the beam with a torque of 56.0 Nm (5.60 kgf·m). Install removed items.

After installing the engine, check their tightening.

Removal of an arm of the left support of the engine is necessary for carrying out in a following order. Prepare fixture «00.0.200» and disconnect «-» terminal from AB. Raise the engine with the tool «00.0.200» by 5 mm. Remove the engine accessory guard and stiffening plate. Remove the left screen of the engine compartment and disconnect the loop from the oil pressure sensor.

Loosen the nut (1. fig. 6.129) fastening the engine bracket to the body.

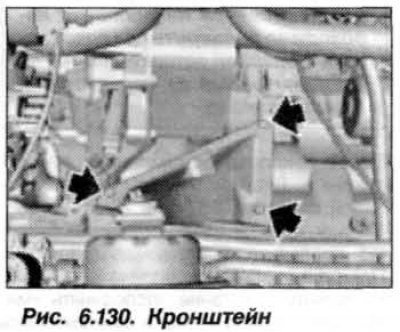

Remove bolts (arrows, fig. 6.130) and remove bracket (1) left engine mount from the engine block.

Installation of the left engine mount bracket should be carried out in the reverse order, if necessary. bolts (1) M8 (8.8) fastening the bracket to the engine tighten the torque 19.0 Nm (1.90 kgf·m). Nut (1) M10 (10.9) tighten the bracket to the beam with a torque of 56.0 Nm (5.60 kgf·m). Install removed items. After installing the engine, check their tightness.