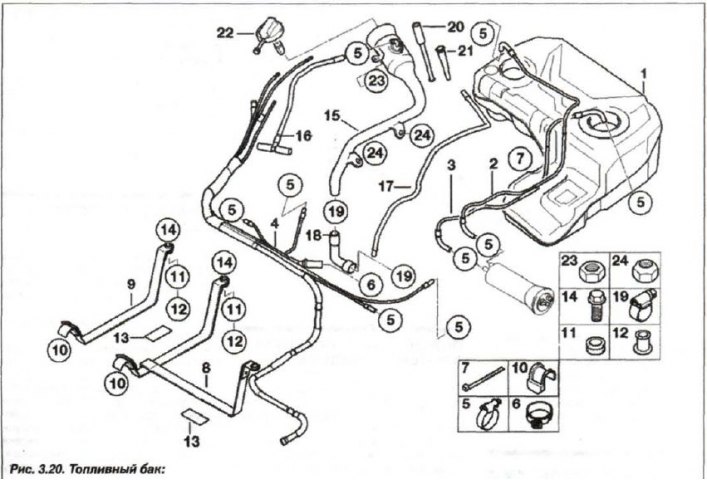

1 - fuel tank; 2 - supply pipeline; 3 - drain pipeline; 4 - pipelines; 5, 19 - collar; 6 - clamp; 7 - bandage; c, 9 - tape; 10 - damper; 11.12 - bushing; 13 - overlay; 14 - bolt; 15 - filling pipeline; 16 - pipeline; 17, 20 - drain pipeline; 18 - hose; 21 - nozzle; 22 - neck cover; 23, 24 - nut; 25 - fuel filter with pressure regulator

The suction jet pump, located in the left tank of the fuel tank, pumps fuel into the right tank through the equalizing pipeline. The suction jet pump is connected via the fuel return line from the injection system pressure regulator.

The pressure limiting valve sets the required pressure to operate the suction jet pump. The fuel return line has a drain safety valve. The valve closes when pressure drops in case of damage or disconnection of the fuel return line, which prevents fuel from flowing out of the tank in extreme situations (strong roll, upheaval).

A non-return valve installed in the filler pipe prevents fuel from splashing back into the filler pipe after the fuel nozzle is turned off. The fuel tank is equipped with a leak diagnostics module. Kingston on the underside of the expansion tank prevents the system from overflowing when refueling. Fuel. rising in the filling vent pipeline, closes the kingston, thereby creating excess pressure in the tank, which prevents its further filling.

The fuel tank is equipped with a ventilation system due to the selection of fuel vapors into the expansion tank and then into a container with activated carbon - an adsorber, which is purged with outside air. Fuel vapor entering the expansion tank condenses and flows back into the fuel tank. The remaining fuel vapors from the expansion tank through the curtain valve are sent to the adsorber, where activated carbon traps fuel vapors.

The purified air exits through the exhaust pipe, the tank leak detection module and the dust filter. The shutter valve on the top side of the expansion tank closes when the vehicle rolls over, preventing fuel from entering the activated carbon filter. The activated carbon filter is restored by blowing it with outside air.

ECU-KSUD opens the fuel tank ventilation valve and the discharge of the inlet pipeline is transferred to the adsorber purge pipeline. Air is drawn in through the tank leak detection module and the dust filter. Activated carbon that has bound the fuel components is blown through. Air saturated with fuel vapors, through the fuel tank ventilation valve, enters the engine combustion chamber for subsequent combustion. The fuel tank vent valve and the fuel tank diagnostic module are controlled by the DME-ECU.

The fuel tank capacity is 93 liters of unleaded gasoline with an octane rating of 95, gasolines with an octane rating of 91 or 98 can be used (critical) fuel volume is signaled by an indicator on the instrument panel.