Attention! After installing the fuel tank, before the first start of the engine, measure the electrical resistance between the ground flag (at the filler neck of the fuel boom) and wheel hub. It should be about 0.6 ohm.

Pour into the fuel tank at least 6-7 liters. fuel.

Do not damage seals.

Removing the fuel tank is the same for all X5/E53 series car models.

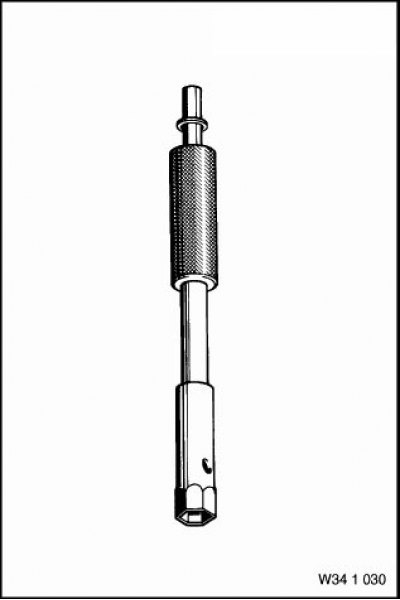

Removing the fuel tank must be carried out in the following order. Dry the fuel tanks. Using fixture «34.1.030», unscrew the locknuts and adjusting sleeves from the parking brake cables.

Remove the rear seat and remove the rubber plugs from the protective mat. Loosen the nuts securing the metal covers (left and right).

Disconnect loop (1. fig. 3.151) from the tank filling level sensor installed in the left tank.

Disconnect the AL from the supply unit in the right tank. Loosen the clamp and disconnect the fuel tank vent line (see right tank).

Remove driveshaft assembly.

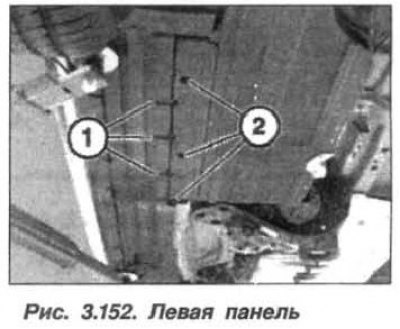

Remove the self-tapping screws on the left fuel tank guard. Release screws on protective cover for left wheel housing. Bend the protective cover and unscrew the bolt (1, fig. 152).

Loosen the screws and nuts securing the panel. Remove the left panel towards the bottom.

When removing the right protection panel, proceed in the same way, bending the protective cover of the right wheel arch and unscrewing the bolt (1, fig. 3.153).

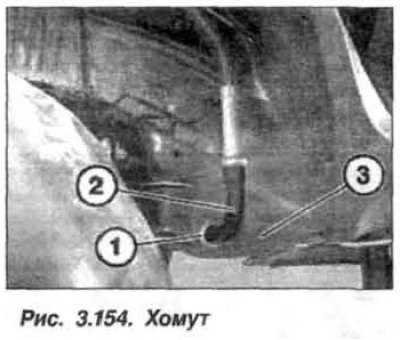

Unclip and disconnect parking brake cables from fuel tank. Remove the fuel filter by unscrewing the bolts and opening the clamps of its fastening. Disconnect the ventilation line from the tank when filling. Remove the rear, right wheel and its protective cover. Loosen clamp (1, fig. 3.154) and disconnect the hose (2) from fuel tank (3). Replace clamp.

Using a fabric tape, mark the following pipelines before and after the connection line (pic. 3.155):

- 1. bypass (∅ 8 mm);

- 2. tank ventilation (∅ 8 mm);

- 3. bypass (∅ 8 mm);

- 4. Ventilation when filling (∅ 18 mm);

- 5. ventilation when filling (∅ 18 mm).

Open the hose clamps so that the clamps do not have to be pulled through the hole in the wheel housing.

Support the fuel tank with a jack over a large surface of wood, but so that the tie-down bands are free.

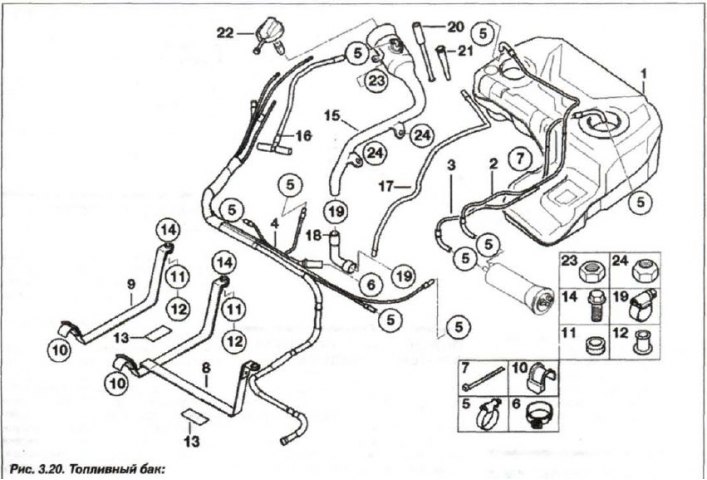

Remove rear right bolt (14, see fig. 3.20) ribbons (9) fuel tank mounts (1), unhook and remove the strap.

1 - fuel tank; 2 - supply pipeline; 3 - drain pipeline; 4 - pipelines; 5, 19 - collar; 6 - clamp; 7 - bandage; 8, 9 - tape; 10 - damper; 11.12 - bushing; 13 - overlay; 14 - bolt; 15 - filling pipeline; 16 - pipeline; 17, 20 - drain pipeline; 18 - hose; 21 - nozzle; 22 - neck cover; 23, 24 - nut; 25 - fuel filter with pressure regulator

Remove rear left bolt (14) and middle tape bolt (8) fuel tank mounts (1), unhook and remove the strap.

Carefully lower the fuel tank by 20 cm and remove the pipe bundle from the wheel arch (1, fig. 3.156).

Carefully lower the fuel tank further and put it aside.

To disconnect the pipeline from the activated charcoal tank, use the tool «16.1.050» (1. fig. 3.157).

The installation of the fuel tank should be carried out in the reverse order, while paying attention to the presence of a damper (10. see fig. 3.20) in both grips.

Pay attention to the rubber-metal hinges and spacers in the holes of the tie-down bands for the fastening bolts. wide belt (arrow, fig. 3.158) on the spacer indicates the head of the bolt.

bolts (M8) fastening of the clamping bands tighten the torque 20-23 Nm (2.0—2.3 kgf·m). Replace clamps and tighten to torque:

- ∅ 10 - 16 mm 2.0 Nm (0.2 kgf·m);

- ∅ 37 - 43 mm 4.0 Nm (0.4 kgf·m).

Adjust the parking brake actuator.