Attention! The power steering pump is replaced as an assembly only. Before installing the pump, fill its internal cavity with liquid for hydraulic systems of the type «ATF Dexron II D» (Shell ATF Dexron II D-21–633). Inject liquid from the suction side by turning the pump pulley until liquid emerges from the discharge side.

The crankshaft and pump pulleys must be in the same plane.

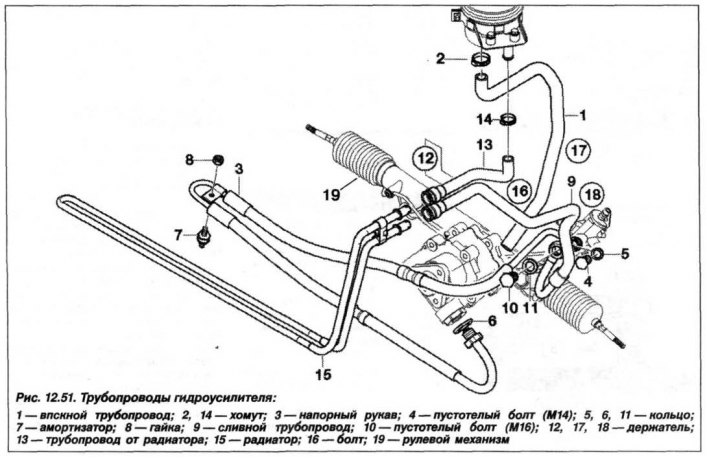

The ring seals of the pipeline installed in the annular recess of its fitting must be replaced when the pipeline is installed on the pump.

Close open pipelines and openings in the pump with plugs / caps to prevent contamination of the system.

Power steering pump on the M54 engine

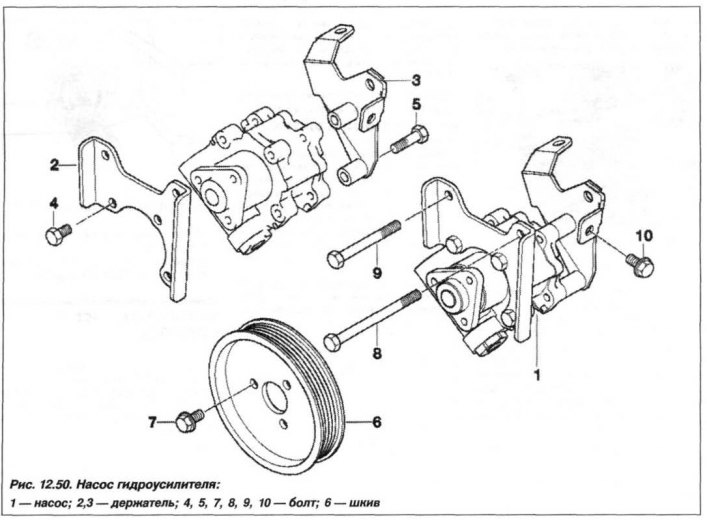

Principal layout of the power steering pump mounting on the engine «M54» is shown in figure 12.50, the location of pipelines is shown in figure 12.51. Power steering pump (ZF, 1, fig. 12.50) mounted on holders (2,3), attached to the engine block.

Replacing the power steering pump must be carried out in the following order. Using a clean syringe, draw fluid out of the power steering reservoir and dispose of it.

Remove the crankcase protection panel. Mark direction of rotation and remove drive belt. Mark the location of the hydraulic lines (pressure and drain). Disconnect the suction and pressure lines from the pump.

Loosen the fixing screws (arrows, fig. 12.52) and remove the power steering pump.

The installation of the pump should be carried out in the reverse order, while it is necessary to replace the seals of the hollow bolts, and the bolts themselves (M14x1.5x26) tighten torque 33 Nm (3.5 kgf·m). Tighten the pump mounting bolts to a torque of 20 Nm (2.0 kgf·m). Tighten the union nut of the pipeline to a torque of 36 Nm (3.6 kgf·m). Fill and bleed the power steering system, check the system for leaks.

Replacing the power steering pump on engines «M57», «M62» And «N62» carried out in the same way, using hollow bolts (M16x1.5x28), which are tightened with a torque of 39 Nm (3.9 kgf·m). On the engine «N62» the pressure pipe of the power steering pump is connected with a union nut, which is tightened with a torque of 36 Nm (3.6 kgf·m). Tighten the pump mounting nuts/screws to a torque of 21.4 Nm (2.14 kgf·m).