- camber angle – 1°50′±10′;

- wheel toe angle – 0°18′±20′;

- the geometric axis of the motion trajectory is 0°± 12′.

The control measurement of the chassis parameters must be carried out after the following work has been completed. When loosening threaded connections:

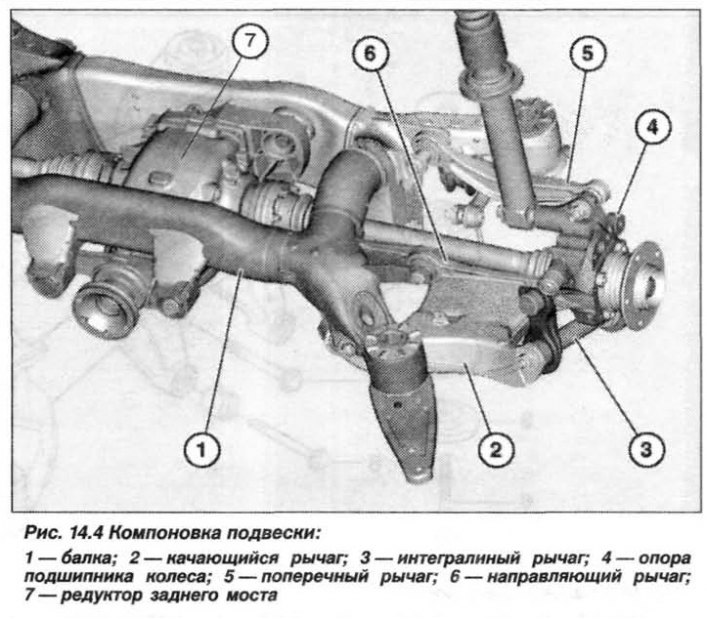

- swing arm to the rear axle beam, front and rear;

- guide lever to the rear axle beam;

- transverse link to the rear axle beam.

When replacing components and parts:

- rear axle beams;

- swing arm;

- integral lever;

- wheel bearing support (spherical bearing);

- transverse arm;

- guide lever.

The layout of the rear suspension is shown in Figure 14.4.

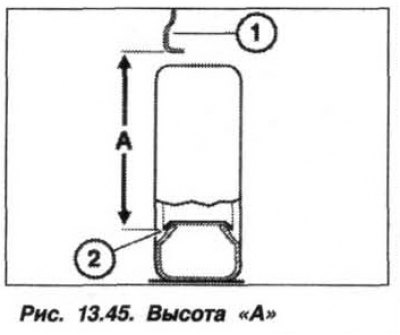

body height size «A» (see fig. 13.45), the distance between the edge of the wheel rim and the lower edge of the casing of the wheel arch along the perpendicular passing through the center of the wheel. Value «A» depends on vehicle model, damping system and tire size (Table 14.1). In this case, the difference in deviation from the specified value between all wheels should not exceed±10.0 mm.

Table 14.1. ride height

| Type of suspension | Vehicle Model | ||

| 3.0i/3.0d | 4.4І | 4.61s | |

| steel spring | |||

| rim 17″ | 687 | — | — |

| rim 18″ | 700 | — | — |

| rim 19″ | 713 | — | — |

| rim 20″ | 726 | — | — |

| Single axle pneumatic, no low landing | |||

| rim 17″ | 695 | 687 | — |

| rim 18″ | 708 | 708 | 706 |

| rim 19″ | 721 | 721 | 718 |

| rim 20″ | 734 | 734 | 731 |

| Two-axle pneumatic, no low landing | |||

| rim 17″ | 687 | 687 | — |

| rim 18″ | 700 | 700 | — |

| rim 19″ | 713 | 713 | — |

| rim 20″ | 726 | 726 | — |

| Two-axle pneumatic, low-slung | |||

| rim 17″ | 672 | 672 | — |

| rim 18″ | 685 | 685 | — |

| rim 19″ | 698 | 698 | — |

| rim 20″ | 711 | 711 | — |