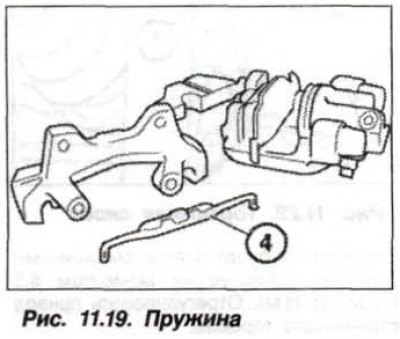

Remove brake spring (4, fig. 11.19) and remove the brake pads.

Attention!

Risk of injury! During subsequent operations, the caliper piston experiences a lot of force - up to 2800 N.

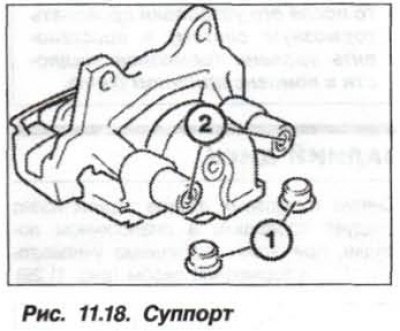

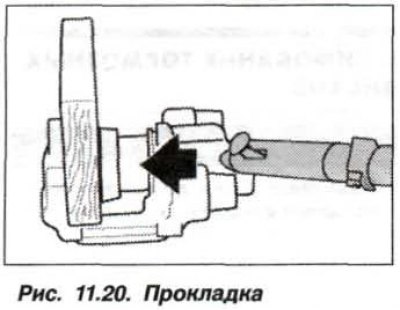

To protect the piston, insert a safety gasket into the groove of the caliper (1, fig. 11.20) hardwood or hard felt. Carefully press out the piston by blowing compressed air through the brake fluid inlet.

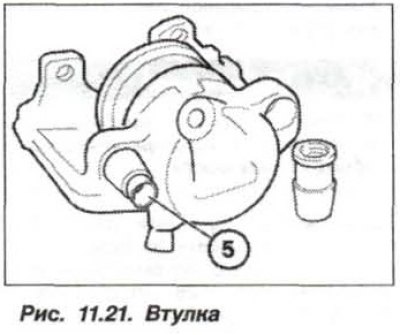

Check guide bushings (5, fig. 11.21) if necessary, install the guide bushing from the repair kit.

Using a plastic needle (pic. 11.22), carefully remove the O-ring. Clean the cylinder cavities and caliper parts with alcohol and dry them with compressed air. Carefully check the cylinder bore, piston and flange surfaces for damage. Turning or grinding of cylinders and pistons is not allowed.

Assemble the caliper in the reverse order, if necessary. Apply a thin coat of Ate Brake Cylinder Paste to the cylinder bore, piston and sealing collar.

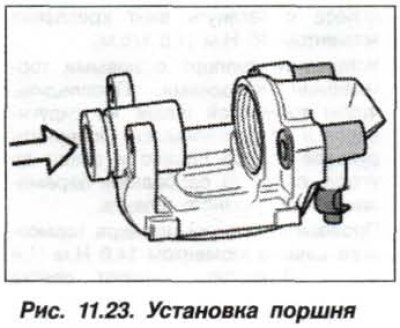

Insert a new seal into the rear groove of the cylinder. Without distorting the piston, press it into the cylinder using a block made of hard wood (arrow, fig. 11.23).

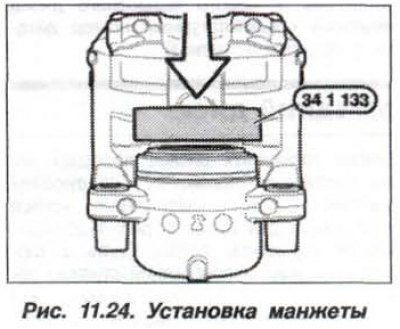

Evenly, with the help of a fixture «34.1.133» (pic. 11.24), press on the dust cap as far as it will go. In order for it to properly fit into place, it is necessary that the area between the cuff and the caliper body remains dry.

Attention! Do not allow paste type Ate and brake fluid to get on the seal and its installation surface.

Set clean (not lubricated) guide pins and tighten with a 7 mm wrench, their torque is 30.5 Nm (3.05 kgf·m). Make sure that the dust seal is correctly positioned in the piston.

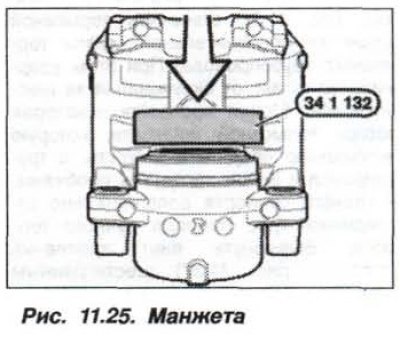

The bulkhead of the brake caliper of the rear wheel should be carried out in a similar manner, while it must be borne in mind that when installing the cuff (pic. 11.25) fixture is used «34.1.132» instead of a fixture «34.1.133».