Attention! When commissioning a new compressor, the following conditions must be met:

- turn off the air conditioner, bring all the ventilation grilles on the front panel to the position «Open», start the engine and let it run at idle;

- set the fan flow to at least 75%, turn on the air conditioner and let it run for at least 2-3 minutes at idle speed, exceeding the speed will lead to failure of the air conditioning compressor;

- if the air conditioner has been left open for more than 24 hours, replace its dryer element;

- Refrigerant oils are hygroscopic and must be stored in closed containers.

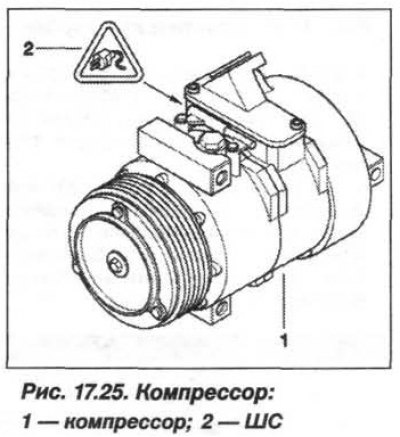

The design of the air conditioning compressor is shown in Figure 17.25.

When the refrigerant is pumped out of the air conditioner, refrigerant oil comes out with it and is collected in the oil separators of the service unit (arrow, fig. 17.26).

After recovery, the refrigerant must be cleaned in a service unit, as there may still be a mixture of refrigerant and oil in the oil separator.

During the cleaning process, the refrigerant is completely converted into a gas and only the refrigerant oil previously bound in the refrigerant remains in the oil separator. This quantity (A) refrigerant oil, measure and record.

The refrigerant oil remaining in the compressor is completely drained through the filler neck into the measuring vessel (pic. 17.27). Measure the amount of refrigerant oil collected (IN), still in the compressor. The refrigeration oil drained from the compressor and pumped out from the oil separator of the service unit must be disposed of.

Depending on the type, a new compressor is factory filled with 120–200 g of refrigerant oil. Unscrew the filler cap and drain the oil contained in the compressor into a clean reservoir.

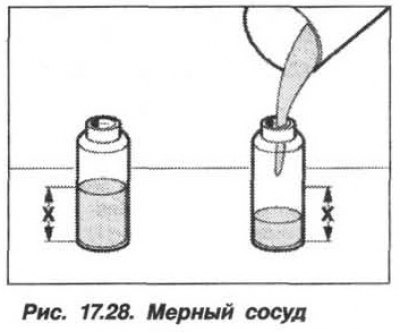

Pour into a measuring vessel an amount of new refrigerant oil equal to that remaining in the compressor (IN), by adding 10 g (pic. 17.28) to ensure sufficiency and pour this amount of oil into the new compressor. It is allowed to use oil drained from a new compressor.

Replace the sealing ring and tighten the filler cap to a torque of 29–31 Nm (2.9–3.1 kgf·m). The rest of the new refrigerant oil can be drained into the service unit's spare oil tank. When installing a new compressor, it is necessary to refill the system with refrigerant before filling the air conditioner with an amount of (A) refrigerant oil previously recovered.

Air Conditioning Compressor Replacement («M54»)

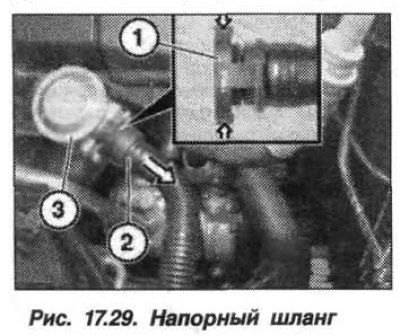

Removing the air conditioning compressor installed on a car with an engine «M54» must be done in the following order. Extract the refrigerant from the air conditioner. Squeeze retaining ring (1, fig. 17.29), disconnect the pressure hose (2) from shutoff valve (3) in the direction indicated by the arrow and move it aside.

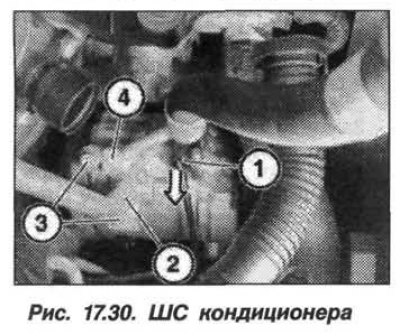

Disconnect loop (1, fig. 17.30) air conditioner in the direction of the arrow. Remove bolts (3) and remove pipes (2) And (4).

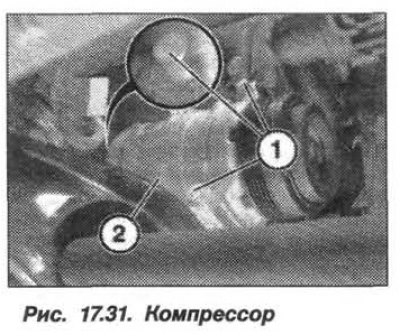

Remove the front engine accessory protection panel, the air conditioning compressor drive belt and take measures to prevent the compressor from falling (2, fig. 17.31), unscrew the bolts (1) and remove the compressor (2) conditioner. The installation of the air conditioning compressor should be carried out in the reverse order, while it is necessary to replace the sealing rings of the pipelines and tighten the fastening of the pipelines to a torque of 20 Nm (2.0 kgf·m).

Air Conditioning Compressor Replacement («M62»)

Removing the air conditioning compressor installed on a car with an engine «M62» must be done in the following order. Extract the refrigerant from the air conditioner, drain the coolant, remove the air conditioning compressor drive belt and the air filter housing.

Disconnect the plastic tube (1, fig. 17.32) from the shut-off valve and from the pump and remove it. Remove bolts (2) and remove pipes (3). Disconnect the coolant hose from the thermostat housing cover.

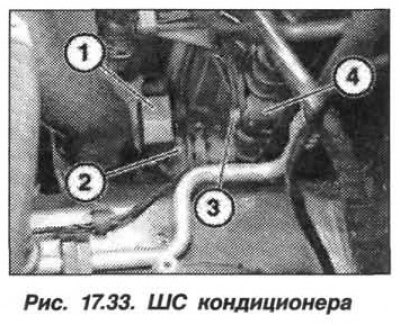

Disconnect loop (1, fig. 17.33) conditioner. Disconnect water hose (2) from the radiator of the cooling system and remove it. Remove bolt (3) and remove the mounting plate (4) from the radiator.

Note. Cover side member in area of A/C compressor with protective material.

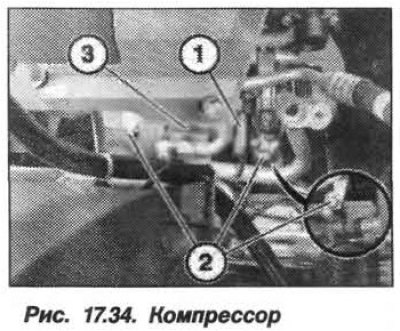

Disconnect loop (1, fig. 17.34) from the air conditioning compressor. Take measures against the fall of the compressor, unscrew the bolts (2) and remove the compressor (3) conditioner upwards.

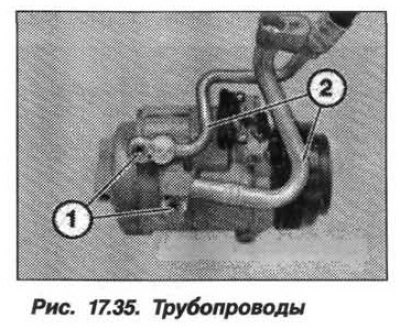

When replacing the air conditioning compressor, it is necessary to unscrew the bolts (1, fig. 17.35) and disconnect the pipes (2).

The installation of the air conditioning compressor should be carried out in the reverse order, while it is necessary to replace the sealing rings of the pipelines and tighten the fastening of the pipelines to a torque of 20 Nm (2.0 kgf·m).

Air Conditioning Compressor Replacement («M57»)

Attention! The air hoses to be installed must be dry and free from grease.

Removing the air conditioning compressor installed on a car with an engine «M57» must be done in the following order. Extract the refrigerant from the air conditioner. Remove the front engine accessory guard and A/C compressor drive belt.

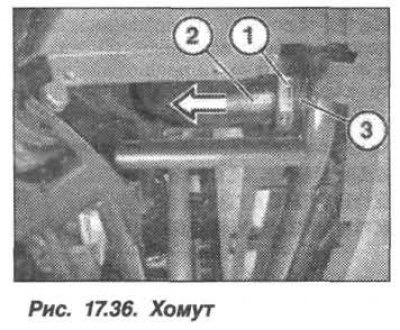

Loosen clamp (1, fig. 17.36), disconnect the lower pressure hose (2) from charge air cooler (3) in the direction indicated by the arrow and move it aside. Remove fan shroud and washer reservoir and set aside.

Loosen clamp (1, fig. 17.37), disconnect pressure pipe (2) from the top pressure hose (3) in the direction of the arrow and remove it.

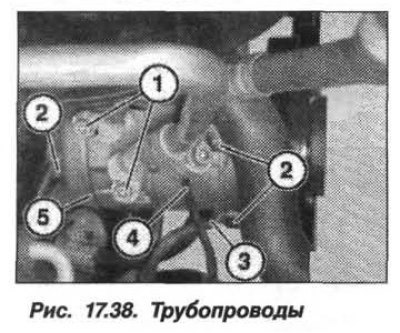

Remove bolts (1, fig. 17.38) and remove the pipes. Disconnect loop (4) air conditioning compressor control. Take measures against falling compressor (5), unscrew the bolts (2) and remove the compressor (5) conditioner.

Installation of the A/C compressor should be carried out in reverse order, making sure that the air hoses are dry and free of grease. Replace the sealing rings of the pipelines and tighten the fastening of the pipelines to a torque of 20 Nm (2.0 kgf·m).