Attention! The troubleshooting process described below by measuring pressure is only possible on vehicles with an unregulated air conditioning compressor.

Troubleshooting in by measuring pressure must be carried out in the following order. Prepare the MoDiC unit or DIS tester for operation, connect it to the vehicle and display the temperature value in the evaporator on the display screen. Install a thermometer 5 cm from the ceiling of the passenger compartment, bring its indication out of the passenger compartment (mirror).

Warm up the engine and bring it to partial load mode (speed 2000 min-1). Close all doors and windows, set the recirculation mode. Select the air distribution mode for the footwell and the heated glass mode. Set the temperature and fan speed to maximum. Warm up the air in the passenger compartment to 40°C and turn on the air conditioning compressor.

At an ambient temperature of +20 to +40°C, pressure within the following limits is considered normal:

- at the inlet 1.0–2.2 bar (kgf/cm2);

- outlet 12.0–22.0 bar (kgf/cm2).

Possible options for instrument readings, the causes of the malfunction and how to eliminate them are given below.

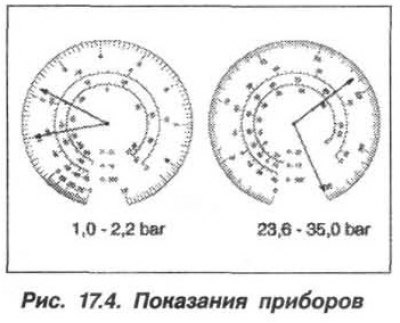

Normal inlet pressure (1.0–2.2 bar) and high outlet pressure (23.6–35.0 bar) indicates that the system is overfilled with R134a refrigerant, the condenser is dirty, or the auxiliary fan is faulty (pic. 17.4).

To eliminate it is necessary:

- drain, vacuum and refill the air conditioner;

- clean the outside of the condenser;

- check and, if necessary, replace the auxiliary fan.

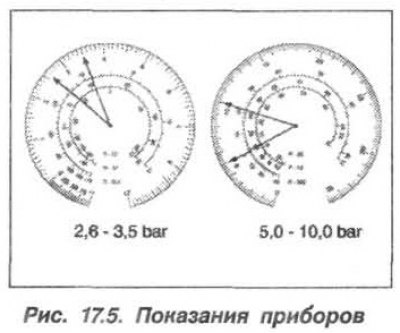

High inlet pressure (2.6–3.5 bar) and low outlet pressure (5.0–10.0 bar) indicates a compressor failure (pic. 17.5). To fix the problem, the compressor must be replaced.

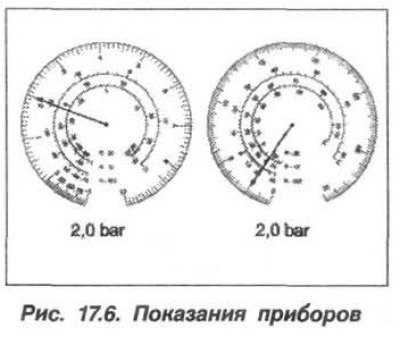

With equal inlet pressure (2.0 bar) and at the exit (2.0 bar), the compressor does not work (pic. 17.6).

To troubleshoot it is necessary:

- if the compressor anti-icing protection has tripped, check the air conditioner evaporator sensor and the power supply to the compressor clutch;

- check the compressor clutch by turning it by hand.

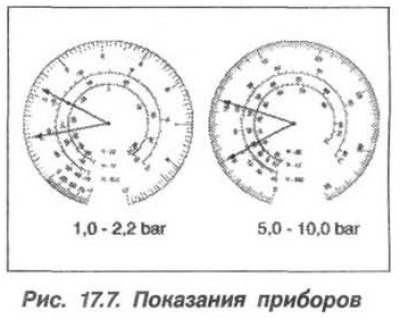

Normal inlet pressure (1.0–2.2 bar) and low outlet pressure (5.0–10.0 bar) indicates a low level of R134a refrigerant in the system (pic. 17.7).

To troubleshoot it is necessary:

- pump out R134a refrigerant from the system and measure its quantity (440±10 g.);

- if the pumped out quantity is correct, check the safety valve for permeability and, if necessary, replace it;

- then evacuate and refill the air conditioner with R134a refrigerant.

- drain, vacuum and refill the air conditioner;

- clean the outside of the condenser;

- check and, if necessary, replace the auxiliary fan.

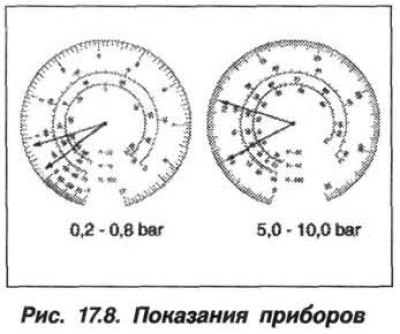

Low inlet pressure (0.2–0.8 bar) and at the exit (5.0–10.0 bar) indicates evaporator icing or blockage on the high pressure side downstream of the condenser or on the low pressure side (pic. 17.8).

To eliminate it is necessary:

- check and, if necessary, replace the evaporator sensor;

- check the patency of the dryer, safety valve and pipelines in these areas, clean or replace them if necessary.

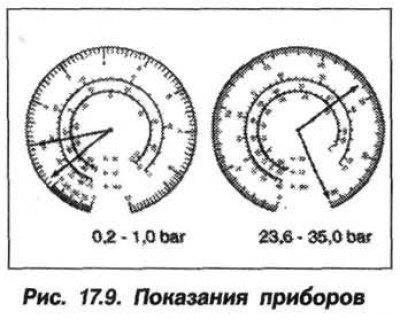

Low inlet pressure (0.2–1.0 bar) and high outlet pressure (23.6–35.0 bar) indicates blockage in the condenser section (pic. 17.9).

To eliminate it, it is necessary to check the patency of the condenser and, if necessary, clean it or replace it.