Withdrawal

1. Disconnect the negative cable from the battery. Remove the cylinder head cover.

2. Remove drive belts (see Section Replacing drive belts and their tensioners).

3. Drain the engine cooling system.

4. Remove the vacuum pump (see Section Removal and installation of the vacuum pump).

5. Remove the lower engine guards and loosen the turbocharger bracket bolts.

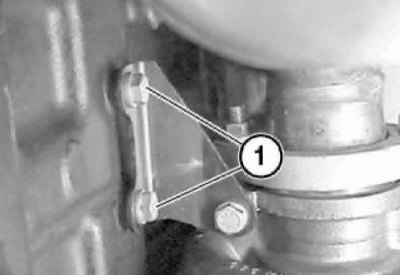

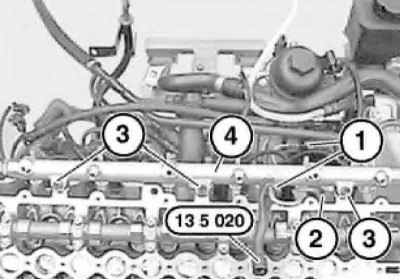

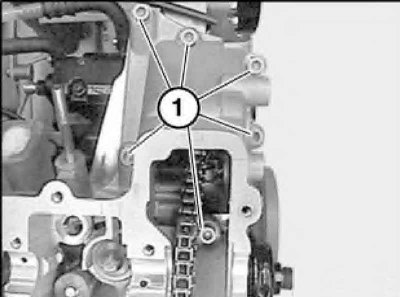

6. Using special tool no. 13 5 020, remove the high pressure pipe (1).

When installing, make sure the rubber cushion is in the correct position (2). Remove the bolts (3) and remove the fuel rail (4).

7. Disconnect the turbocharger from the exhaust manifold.

Installation will require a new turbocharger gasket; lubricate the threads with copper-containing grease.

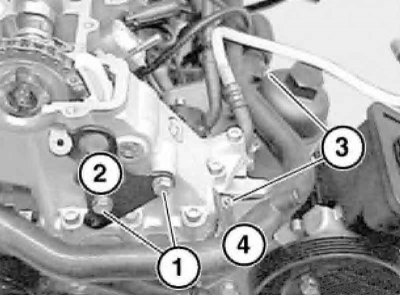

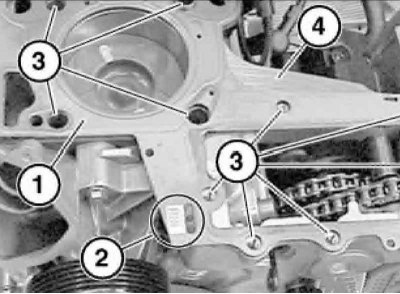

8. Remove screws 1 and 3 and remove eyelet 2 and return tube 4.

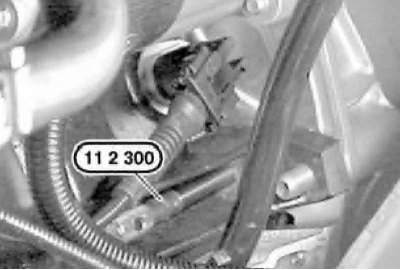

9. Remove the plug from the rear of the crankcase, below the starter, and turn the engine clockwise using tool no. 11 6 480 on the front of the vibration damper. Fix the engine in the position of the piston of the first cylinder at TDC of the end of the compression stroke by inserting tool No. 11 2 300 into the hole opened under the plug.

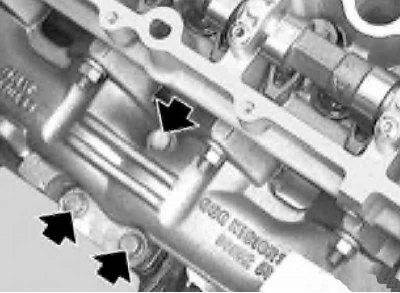

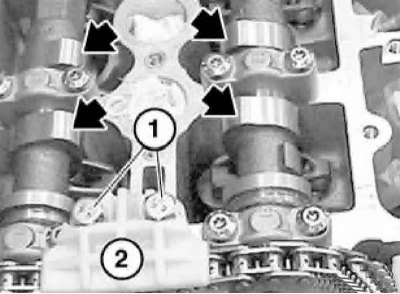

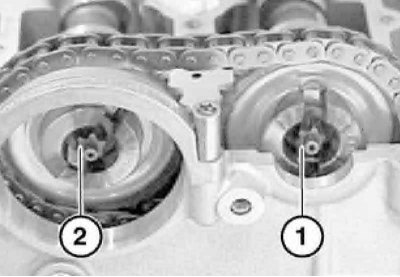

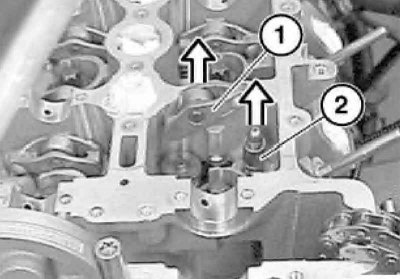

10. In the TDC position, the tops of the camshaft cams that control the valves of the first cylinder must be directed towards each other (arrows). Remove the screws (1) and remove the guide (2) timing chains.

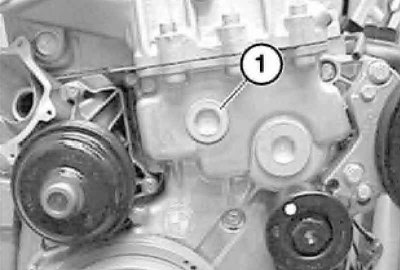

11. Remove the screw plug.

12. Relieve pressure by loosening the chain tensioner bolt.

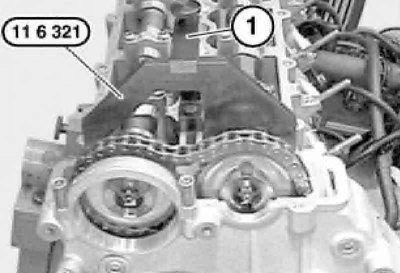

13. Install tool No. 11 6 322 on the cylinder head (1), place special tool no. 11 6 321 on intake camshaft and secure with special tool no. 11 6 322.

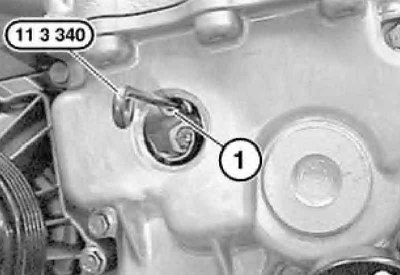

14. Slowly turn the exhaust camshaft on the sprocket mounting bolt clockwise until the chain tensioner is fully compressed, then install tool No. 11 3 340 in the chain tensioner (see illustration).

When removing one or both sprockets without first locking the chain tensioner, the tensioner piston may slip outward, which is a very laborious operation to put back in place.

15. Loosen the bolt (1) on the intake camshaft, and then completely remove the bolt (2) on the exhaust camshaft.

16. Move the exhaust camshaft sprocket forward, lift the chain above it (1) and remove the star (2) in the direction of the arrow.

17. Turn out a bolt of fastening of an asterisk of a camshaft of inlet valves and remove an asterisk.

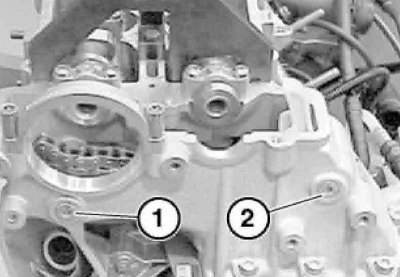

18. Turn out the support pin (1) chain tensioner bars and support pin (2) chain guide.

When installing, replace the removal pins. Pull up the tensioner bar and timing chain guide. Remove tools no. 11 6 321, 11 6 322.

To avoid damage to the valves during the subsequent installation of the camshafts, none of the pistons should be in the TDC position.

19. Remove the tool for fixing the engine in the TDC position (№ 11 2 300). Pull the timing chain up and hold it taut so that the engine can be cranked. Rotate the engine at the vibration damper with special tool no. 11 6 480 by approx. 45° against hour hand.

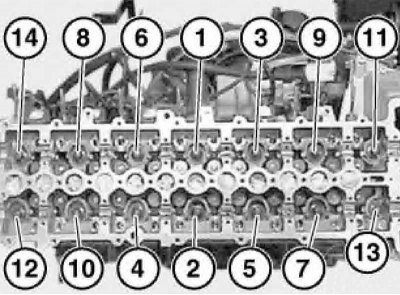

20. Evenly, in several half-turn steps, unscrew the bolts securing the camshaft bearing caps in sequence from the edges to the middle. Remove the bearing caps and set them aside, arranging them in such a way that the bearing caps can be refitted later.

21. Remove the intake camshaft first, and then the exhaust valve shaft.

22. Remove all rockers (1) and hydraulic valve clearance compensators and arrange them in a manner that allows subsequent installation in their original places.

23. Turn out bolts.

24. Turn out bolts of fastening of a head of the block of cylinders in reverse sequences.

The cylinder head bolts must not be reused.

Be careful not to damage the glow plugs protruding from the plane of the cylinder head.

25. If necessary, remove the glow plugs.

26. Remove the gasket (1) cylinder heads, pay attention to the number of holes (2) in the lining. Clean all blind threaded holes (3) from oil, coolant and dirt. Clean the mating surface (4).

Installation

1. If no work has been carried out on the cylinder block that causes a change in the protrusion of the piston bottom, then you should use new head gasket with the same marking (1 cm illustration) thickness as on the old gasket. Otherwise, the repair thickness of the gasket should be re-determined by measuring the protrusion of the bottom of all pistons relative to the plane of the cylinder block. When protruding from 0.92 to 1.03 mm use gasket with 2nd holes, and when protruding over 1.03 mm - With 3rd holes.

2. Check the centering sleeves in the cylinder block for damage and correct installation; replace bushings if necessary.

3. Install new cylinder head gasket and secure the head to the cylinder block new bolts by tightening them in the sequence shown (see illustration).

4. Tighten the bolts (see illustration).

5. Lubricate the beds and bearing caps of the camshafts with engine oil. Reinstall all rocker arms and hydraulic lifters in their original locations.

6. Install camshafts.

Marked on intake shaft «E», and at graduation «A»; bearing caps have the same letter designations, as well as numeric designations indicating the location of the cap, counting from the exhaust side. Establish covers of bearings of camshafts and tighten their fixing bolts.

7. Turn the camshafts by the hexagons so that the tops of the cams of the intake and exhaust valves of the 1st cylinder point to each other.

8. Install the tensioner and timing chain guide bar and secure them new fingers.

9. Center the intake camshaft and fix it with tools No. 11 6 321 and 11 6 322 at the first cylinder piston position at TDC of the end of the compression stroke.

10. Install the fuel distribution line and high pressure fuel pipes.

11. Put the timing chain on the intake camshaft sprocket, slide the sprocket onto the shaft and secure it with a bolt, tightening it to a snug fit and then loosening it by half a turn.

An arbitrary position of the sprocket relative to the camshaft is allowed. Install the exhaust camshaft sprocket in the same way.

12. Install the timing chain guide between the sprockets with a new gasket and tighten the exhaust camshaft sprocket bolt, holding the shaft from turning by the hexagon.

13. Slowly turn the exhaust camshaft clockwise to fully compress the timing chain tensioner and remove the tensioner retainer.

14. Again give on a half-turn a bolt of fastening of an asterisk of a final camshaft.

15. Tighten the chain tensioner bolt and screw in the tensioner service port plug with a new O-ring.

16. Turn the engine clockwise at the vibration damper from 45°before TDC to TDC.

17. Block the crankshaft at TDC using special tool No. 11 2 300.

18. Install tool No. 11 6 321 on the intake camshaft and fix it. Tighten the shaft sprocket bolt using tool no. 00 9 120. Tighten the exhaust camshaft sprocket bolt in the same way.

19. Remove tool No. 11 6 321 from the exhaust camshaft.

20. Pull tool no. 11 2 300 back far enough to free the flywheel (see illustration).

21. Turn the engine with tool no. 11 6 480 twice in the direction of rotation to the first cylinder piston position just before TDC of the end of the compression stroke.

22. Turn the engine in the direction of rotation to the TDC position until tool no. 11 2 300 (fixing pin) locked into place with an audible click.

It is not allowed to turn the engine in the opposite direction.

23. Block the crankshaft in the position corresponding to the TDC of the piston of the first cylinder using tool No. 11 2 300 (see illustration).

24. Fit tool no. 11 6 321 to the intake camshaft.

Special tool no. 11 6 321 must rest without play on the cylinder head.

25. Install tool No. 11 6 321 on the exhaust camshaft so that it rests against the cylinder head without play.

26. Remove tool No. 11 6 321 from the exhaust camshaft. Remove tools no. 11 6 322 and no. 11 2 300.

27. Insert a plug into the service hole to block the flywheel.

28. Install a new seal.

29. Install the turbocharger.

Lubricate the threads with copper paste.

30. Install return tube and lifting eye (see illustration).

31. Tighten the mounting bolts (1) turbocharger bracket.