After installation, it is necessary to bleed the power supply system, preventing the high-pressure fuel pump from running without fuel (dry).

Models with M51 engine

1. Disconnect the negative cable from the battery.

2. Remove the engine crankcase protection.

3. Remove the fan and its shroud (see chapter Engine cooling, heating, ventilation and air conditioning systems).

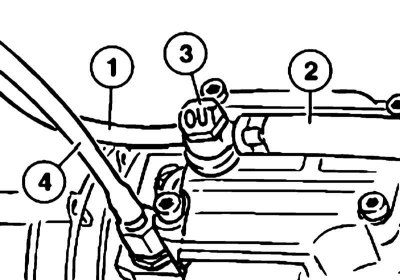

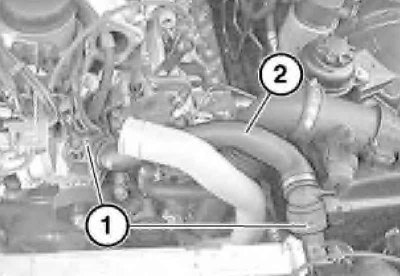

4. Remove the inlet pipeline (see Engine).

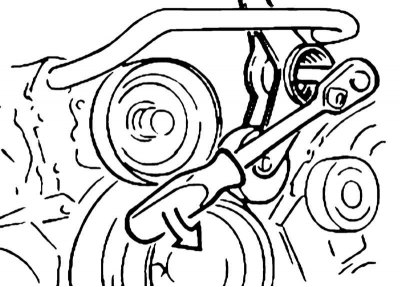

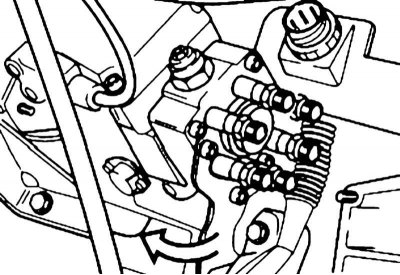

5. Disconnect the hose (1) oil drain, remove the drain pipe (2) and disconnect the fuel line (4).

Replace oil drain hoses.

6. Using a special split key, disconnect the distribution pipelines from the nozzles and from the injection pump. Plug the open holes of the injectors and injection pump.

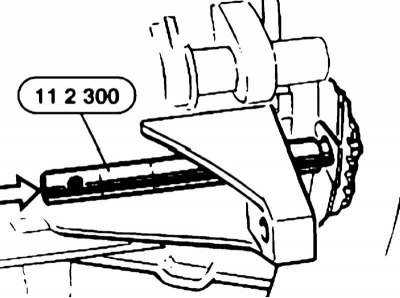

7. Block the engine in the position of the piston of the 1st cylinder at the TDC of the end of the compression stroke by installing tool No. 11 2 300 for this. To make sure that the TDC is set correctly, remove the oil filler cap: the camshaft cam should point up.

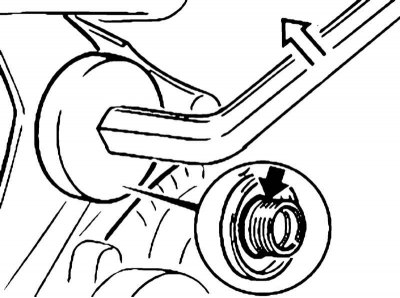

8. Remove the cap nut of the toothed belt tensioner.

During installation, check and, if necessary, replace the O-ring.

9. Give the central nut and screw in its place adaptation No. 13 5 120 without the ejector screw.

10. Remove the generator air blower supply channel.

11. Separate a socket on TNVD.

12. Remove a dustproof cap and give a nut.

13. Turn out bolts on TNVD.

When installing, pay attention to the installation of spacers.

14. Turning the ejector screw into tool no. 13 5 120, separate the injection pump from the sprocket.

Leave tool no. 13 5 120 screwed in until the next installation of the injection pump, otherwise the sprocket will fall and the engine will have to be disassembled. Before installing the injection pump, the ejector screw of tool no. 13 5 120 must be fully unscrewed.

15. Rotate the injection pump clockwise so that the bracket can be passed past the engine support bracket. Remove the injection pump.

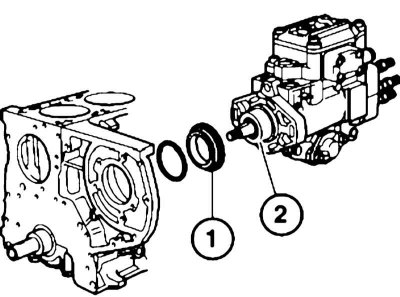

When installing, replace the O-ring on the pump flange.

16. Installation is carried out in the reverse order.

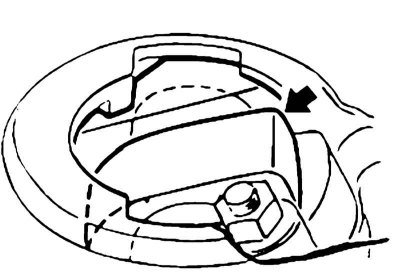

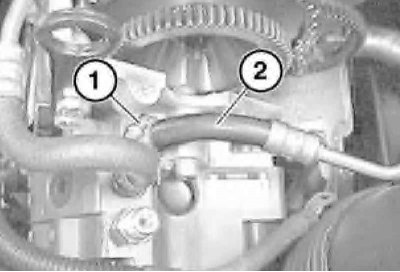

17. Depending on the support of the injection pump, when installing under the mounting hole in the support, it is necessary to install a sealing ring. If the bore diameter (2) equals 68 mm, remove the spacer ring (1).

18. If the injection pump is removed for replacement, move the mounting elements to the new pump.

Models with M57 engine

Close the generator from hit on it of working liquids. The position of the injection pump relative to the timing does not affect its functioning. After disconnecting the pressure pipes, be sure to plug the holes in the injection pump.

1. Remove the inlet pipeline (see chapter Engine).

2. Drain the coolant from the radiator of the cooling system (see chapter Vehicle settings and routine maintenance).

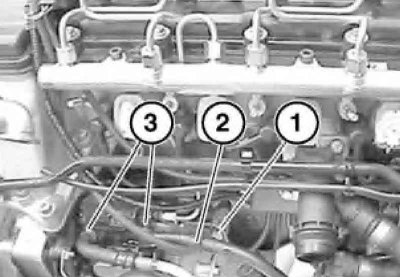

3. Turn out bolts (1), disconnect the water hoses from the return pipe (2) and take it off.

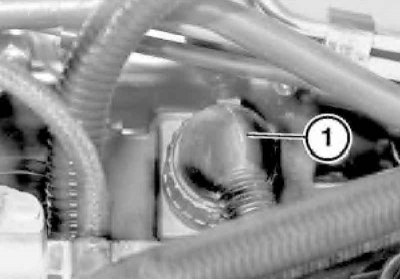

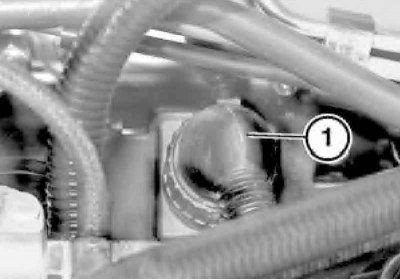

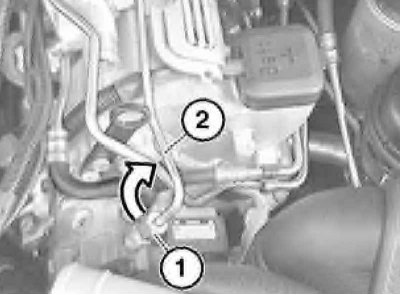

4. Disconnect the connector (1) from the injection pump pressure regulator, loosen the clamps (3) and disconnect the supply and return fuel hoses (2).

When installing, replace the clamps.

5. Disconnect the connector (2) glow plugs. Give the cap nuts (1) fixing the pump piping with special tool no. 13 5 020 and remove the piping.

When installing, pay attention to the correct installation of the rubber-metal hinge (3).

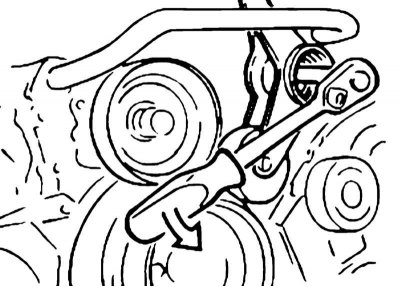

6. Give the nuts for fastening the injection pump and remove the alternator drive belt from the tensioner roller (see chapter Engine).

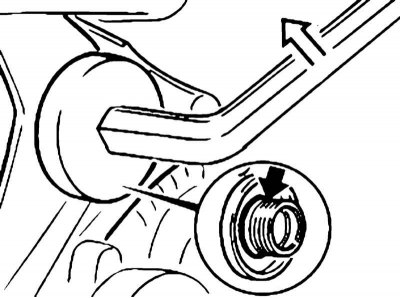

7. Remove the screw plug.

When installing, replace the O-ring.

8. Loosen the injection pump drive sprocket nut, located under the screw plug, and screw tool No. 13 5 192 into its place.

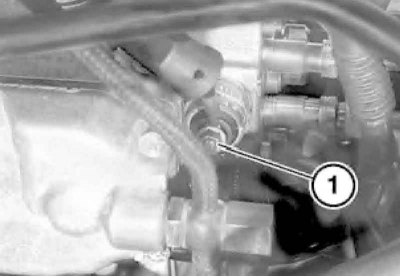

9. Install tool no. 13 5 191 without ejector bolt on the injection pump sprocket, then screw in the ejector bolt (1) first to a tight fit, and then so much that the injection pump separates from the sprocket.

10. Remove the injection pump.

To fix the sprocket, tool no. 13 5 190 must be left on the vehicle and must not be removed under any circumstances.

11. Installation is carried out in the reverse order. To install the high pressure injection pump, remove the ejector screw. Clean mating surfaces and replace injection pump gasket.

12. After installation, to remove air from the power system, turn on the ignition for about 1 minute. During this time, the fuel priming pump is activated and the fuel system is filled with air-displacing fuel.

Models with M67 engine

If the installed charge air hoses are not degreased and damp, the supercharger may fail. After disconnecting the pressure pipes, be sure to plug the holes in the injection pump. The position of the injection pump relative to the timing does not affect its functioning.

1. Remove the engine top covers.

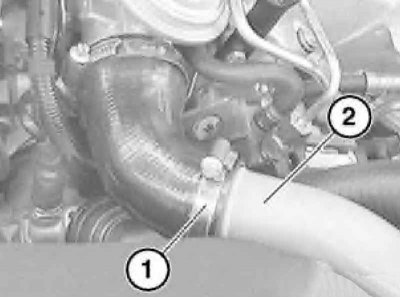

2. Loosen clamp (1) and pull out the pressure tube (2) from the pressure hose.

3. Remove the radiator shroud (see chapter Engine cooling, heating, ventilation and air conditioning systems).

4. Drain the coolant from the radiator of the engine cooling system (see chapter Engine cooling, heating, ventilation and air conditioning systems).

5. Open the latches (1) water hose (2) and take it off.

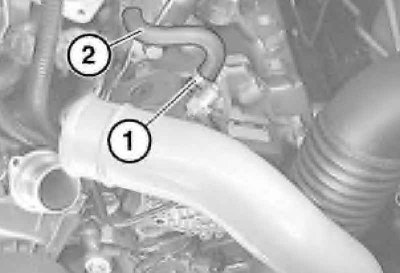

6. Give the union nut (1) and slightly raise the pressure pipe (2).

7. Loosen clamps (1) and disconnect the fuel lines (2).

When installing, replace the hose clamps.

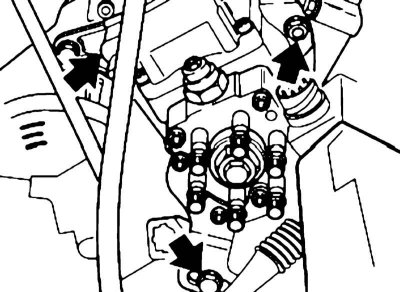

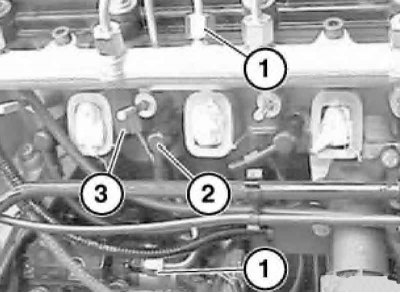

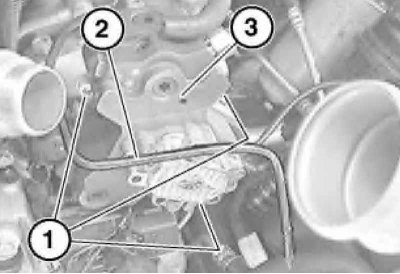

8. Turn out bolts of fastening (1) HPFP and disconnect the shut-off valve connector from the HPFP. Set aside the wire (2) and remove the injection pump (3).

9. Installation is carried out in the reverse order. Replace damaged injection pump sealing ring.