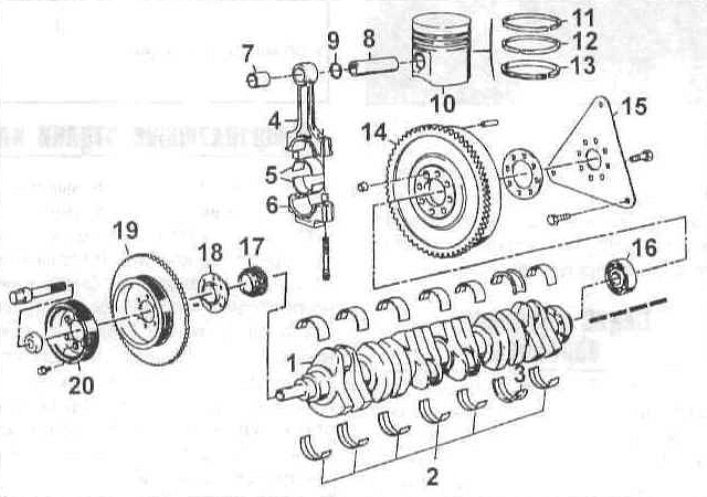

Typical elements of a crank mechanism

1 - crankshaft;

2 - liners of main bearings;

3 - thrust liners;

4 - connecting rod;

5 - connecting rod bearing shell;

6 - connecting rod cover;

7 - bushing of the upper head of the connecting rod;

8 - piston pin;

9 - retaining ring;

10 - piston;

11 - top compression ring;

12 - lower compression ring;

13 - oil scraper ring;

14 - flywheel;

15 - leading flange;

16 - bearing;

17 - crankshaft sprocket;

18 - clutch;

19 - torsional vibration damper;

20 - pulley.

Attention: Before removing the pistons with connecting rods, remove the cylinder head, oil sump and oil pump.

Check with your fingernail for a deposit of carbon deposits at the top of the piston ring travel (about 5 mm below the top of the cylinder). If rollers have formed due to carbon deposits or wear of the cylinder walls, they must be completely removed using a special tool. If the rollers are not removed, then when removing the pistons with connecting rods, the piston can be damaged.

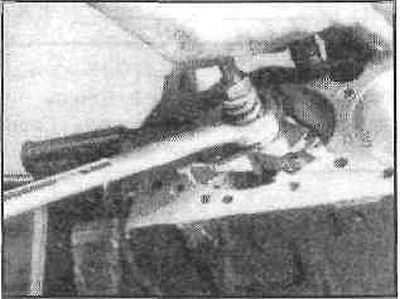

Removing a roller using a reamer

After the rollers are removed, rotate the engine so that the crankshaft is on top.

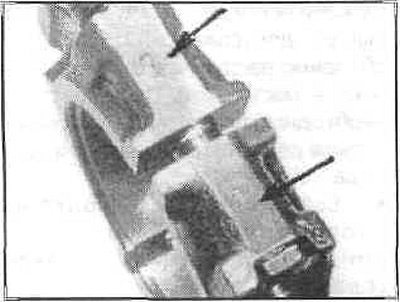

Before removing the connecting rods, check their backlash with feeler gauges. Insert them between the first connecting rod and the shaft crank until all the play is taken out. If the backlash exceeds the limit repair value, then it is necessary to replace the connecting rods. If new connecting rods are installed (or new crankshaft), the play may become less than the minimum allowable. In this case, the connecting rods must be machined - if necessary, consult a car workshop. Repeat the procedure for the rest of the connecting rods.

Check for identification marks on the connecting rods and connecting rod caps.

If they are not visible, use a small punch to mark the appropriate number of marks on each connecting rod and cap (1, 2, etc. according to cylinder no).

Loosen each connecting rod cap nut in 1/2 turn increments until they can be twisted by hand. Remove the #1 connecting rod cap together with the bearing shell - do not drop the shell.

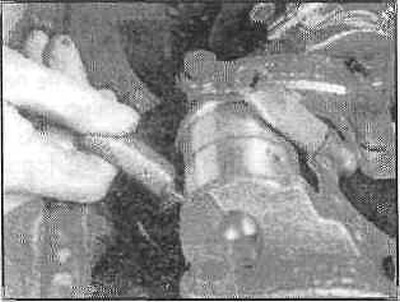

Pull a piece of plastic or rubber hose over each connecting rod cap bolt so as not to damage the crankshaft journal and cylinder bore when the piston is pulled out.

Pull out the bearing shell and push the connecting rod with the piston out through the top of the engine. Push, resting with the wooden handle of the hammer against the surface of the upper bearing of the connecting rod. If resistance is felt, check again that the roller is completely removed from the cylinder wall.

Repeat this operation for the remaining cylinders.

After removing, assemble the connecting rods by installing the bearing shell and caps, and tighten the nuts with your fingers.

Do not disconnect pistons from connecting rods.