M52 series engine oil pump - removal and installation

Withdrawal

Attention: To check the operation of the pressure reducing valve, it is enough to remove the oil sump. The oil pump cannot be removed.

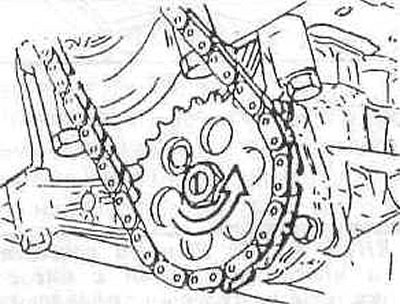

Remove the oil pump. Unscrew the nut, remove the oil pump sprocket along with the chain. At the same time, release the chain tensioner (press it down).

Attention: The nut has a left-hand thread, so to unscrew it, you need to turn it to the right.

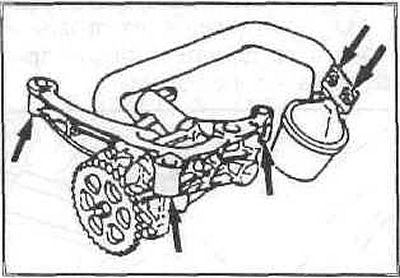

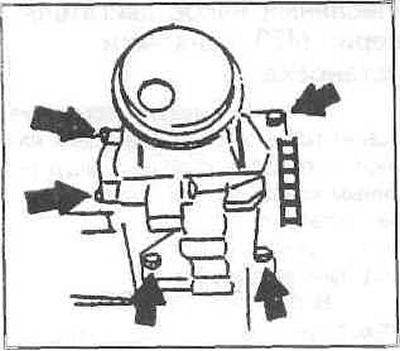

Loosen the oil pump mounting bolts (arrows) and remove the oil pump. Pay attention to the position of the two guide bushings on the cylinder block.

Pull the oil pump back and remove it.

Examination

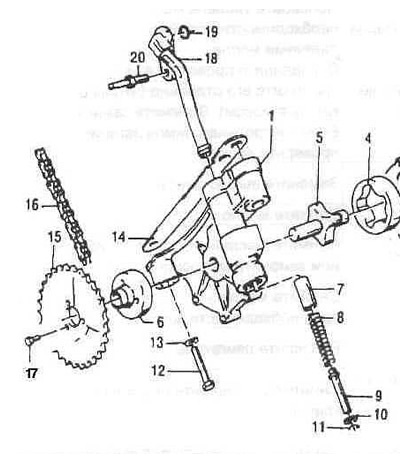

If necessary, disassemble and clean the oil pump in the following order: unscrew the bolts (13) and remove the oil pickup, unscrew the bolts (5) pump housing. Don't Lose the Guide Bushings (4).

Check the rotors (2) And (3) for wear and damage, replace if necessary.

Technical data

The radial play between the outer rotor and the pump housing is 0.18 mm.

Axial play of the inner rotor - no more than 0.08 mm; outer rotor - no more than 0.09 mm.

Remove retaining ring (10) and remove the relief valve. Check the length of the unloaded spring, replace if necessary. The length of the spring should be 84.1 mm.

Attention: O-ring (8) must always be changed. Carefully insert the pressure reducing valve, install the circlip.

Install the oil pickup with a new gasket, the protrusion on the gasket should be directed towards the oil pickup screen.

Lubricate all parts with engine oil, install the oil pump cover and tighten its bolts to 10 Nm.

Installation

Insert the oil pump, tighten its mounting bolts to 20 Nm. Between the cylinder block and the oil pump housing, two centering sleeves must be located. Install the chain sprocket and tighten the left-hand threaded nut to 25 Nm. If removed, install chain tensioner.

Install the oil pan.

M30 series engine oil pump - removal and installation

The oil pump is located at the bottom of the oil sump and is attached to the engine block. The pump is driven by a single row roller chain. To adjust the chain tension, plates can be inserted between the engine block and the pump.

The pressure reducing valve is mounted directly on the pump housing.

Attention: To remove the pump, the oil sump must be removed.

Withdrawal

Raise the car and drain the oil.

Remove the underbody protection.

Disconnect the ground wire from the battery.

Remove the generator.

Remove the water pump, while the wires remain connected.

Unscrew and remove the oil sump forward. Rotate the crankshaft accordingly.

Unscrew the chain sprocket from the oil pump and remove it from the chain. Carefully remove the pads. Remove the pressure reducing valve by unscrewing the mounting bolt.

Unscrew the pump cover. Remove the outer rotor. Rinse all parts.

Examination

Visually check the pump parts for wear.

Install the outer rotor and check the clearance of the rotors.

Required clearances

- Axial clearance rotor-pump housing: 0.04-0.1 mm.

- Gap external-internal rotor: 0.12-0.20mm.

If these clearances are exceeded or there are pits on the parts, the pump must be replaced as a set. The length of the pressure reducing valve spring must be 68 mm, the shorter spring must be replaced.

Installation

The pump is installed in the reverse order, taking into account the following:

With the pump bolted to the engine block, check that the pump moves freely (chain drive not installed yet). If it sticks, then the pump housing is warped. The old pump should be replaced.

Check the flatness of the mounting surface of the new pump. The adjusting plate must be replaced. Select the adjusting plate so that the chain has a play of 3-5 mm on the branch.

The chain must never be overstretched.

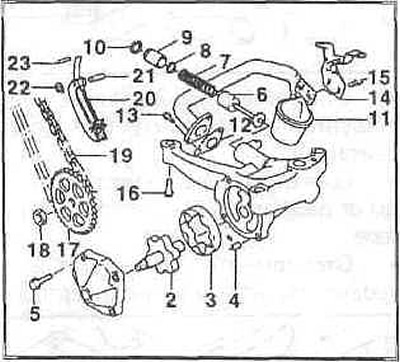

Elements of the oil pump of the M30 series engine

1 - oil pump housing;

2 - cover;

3 - metal gasket;

4 - outer rotor;

5 - internal rotor;

6 - hub;

7 - piston;

8 - clamping spring;

9 - guide tube;

10 - safety ring;

11 - spring washer;

12 - hex bolt;

13 - spring washer;

14 - remote laying (available in 0.1 and 0.6 mm thickness);

15 - asterisk;

16 - chain;

17 - hex bolt;

18 - discharge pipeline;

19 - O-ring;

20 - mounting pin;

21 - hex bolt;

22 - spring washer.

M70 series engine oil pump - removal and installation

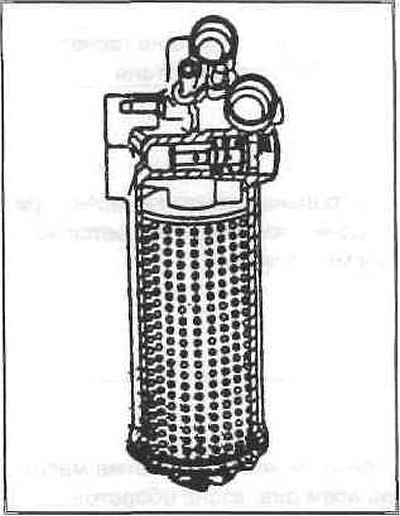

The lubrication system consists of a suction and discharge pump in the sump with a pressure reducing valve, an oil filter with a thermostatic valve and an oil cooler located above the water cooler.

The pump is driven by the crankshaft through a roller chain.

The rear of the pump draws oil from the crankcase and conveys it forward to the discharger. Thanks to this, the engine receives a non-foamed oil, which is absolutely necessary for the perfect operation of the hydraulic tappets.

The pressure reducing valve limits the maximum oil pressure.

At very low temperatures, the valve opens at an oil pressure above 10 bar.

Starting at an oil temperature of 95°C, the thermostat valve in the filter housing allows oil to pass through the oil cooler.

The oil pump can be reached from below after unscrewing the oil sump.

Withdrawal

Attention: The installation sequence shown must be observed.

Loosen the chain sprocket nuts and remove the chain sprocket.

Unscrew the oil line to the oil sump from behind.

Remove the three mounting bolts. Take out the pump.

Unscrew the back cover and take out the rotors. Remove the wedge of the inner rotor from the shaft.

Loosen the front cover and remove the rotors along with the shaft.

The front inner rotor is pressed onto the shaft and must not separate from it.

If there is visible wear, replace the pump as a set.

Screw in the pressure reducing valve plunger and remove the retaining ring with a collet.

Remove plunger with spring.

Examination

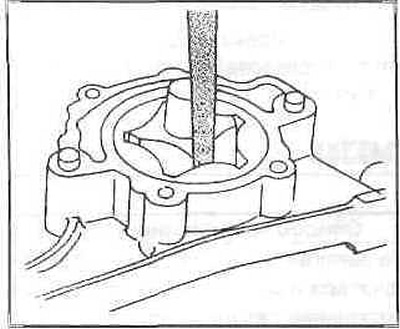

Degrease all parts. Insert the outer rotors into the housing and measure the radial and axial clearances with a flat feeler gauge.

- Axial clearance: 0.04-0.09 mm.

- Radial clearance: 0.12-0.20mm.

To measure the axial clearance, place a ground ruler on the mating surface.

Repeat the measurement with the inner rotor. The axial clearance can be 0.02-0.065 mm.

The pressure relief valve plunger should slide easily into the bore.

The inner rotor of the rear suction pump must sit without play on the wedge shaft.

If there is a very large gap or visible wear, the pump assembly should be replaced.

Installation

The pump is installed in the reverse order of removal.