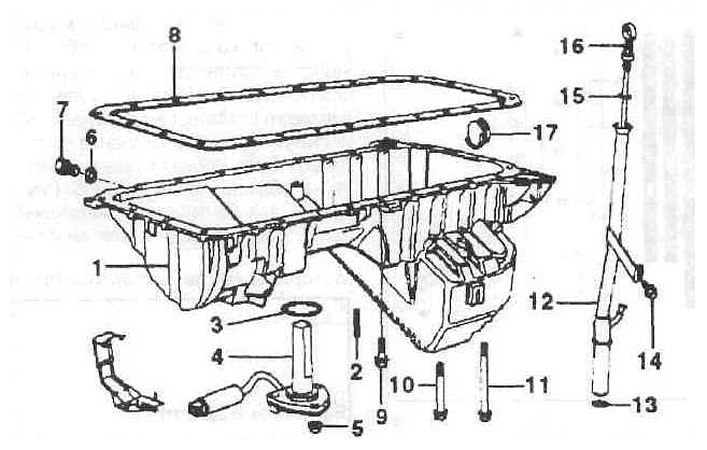

M52 series engine oil sump

1 - oil sump;

2 - hairpin;

3 - sealing ring;

4 - oil level sensor;

5 - nut;

6 - sealing ring size Al2x15.5-AL;

7 - bolt for draining oil;

8 - oil crankcase gasket;

9-11 - bolts;

12 - guide tube oil dipstick;

13 - sealing ring;

14 — a bolt with a six-sided head;

15 - sealing ring;

16 - oil dipstick;

17 - cover.

Withdrawal

Disconnect the ground wire from the battery.

Attention: Due to lack of space to remove the oil sump, both engine mounts must be loosened and the front axle carrier lowered.

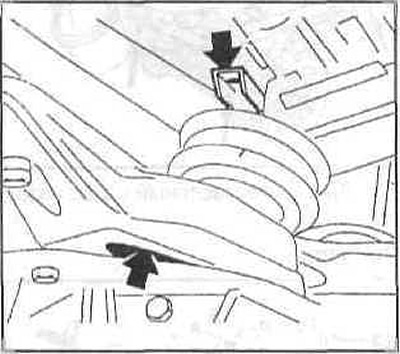

Remove the air filter housing with intake duct from the air filter housing with intake duct from the throttle body and remove it.

Raise and support the vehicle with stands. Remove the lower mudguard of the engine compartment.

Drain the engine oil.

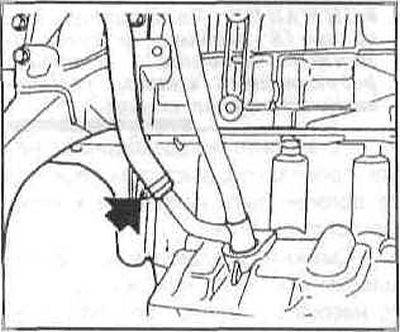

Detach the oil return hose from the oil separator on the dipstick guide tube by loosening the clamp.

Remove the oil dipstick tube bolt from the holder. Pull the guide tube up out of the oil pan, paying attention to the O-ring.

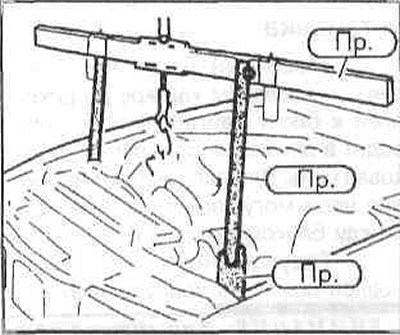

Attach the engine to the winch (lift) and lift it up. If there is no hoist, run a suitable wire through the lugs on the engine, thread a strong pipe through the cable and support it on suitable stands or on the wing supports.

Attention: Do not rest the pipe on the wings! Raise the engine slowly, making sure that the wires and hoses are not stretched or pinched. The engine lift is installed on the left and right.

Raise the engine slowly with a hoist about 5 mm.

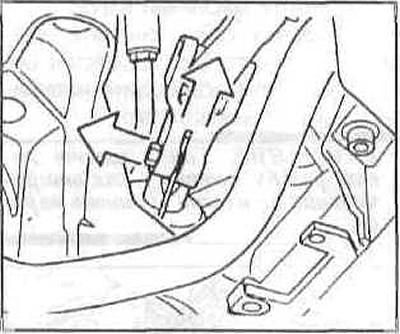

Disconnect the steering shaft from the steering gear (reiki). To do this, unscrew the clamping bolt and remove the cardan joint from the steering mechanism.

Loosen the power steering pump mounting bolts and hang it on the engine with the connected mechanisms using a piece of wire.

Caution: The hoses remain connected to the power steering pump or fluid will leak out. If parts of the hydraulic system are exposed, then great attention must be paid to cleanly those, because. Dirt that gets inside can damage the amplifier.

Loosen the left and right engine mounts from above about four turns.

From the underside of the vehicle, unscrew the bottom nuts of both engine mounts.

If there is, unhook the oil lines from the holders on the oil pan.

Disconnect the oil level sensor plug on the oil sump.

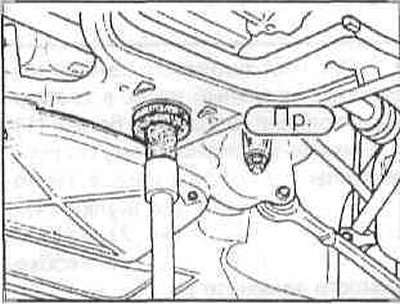

Support the front axle beam with a floor jack and a special support. The figure shows a special tool.

Loosen the front axle beam mounting bolts and lower it as low as possible.

Attention: The steering gear and front suspension arms do not need to be disconnected from the front axle beam.

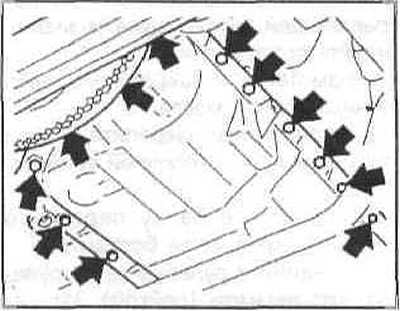

Loosen the crankcase mounting bolts front and rear.

Tilt the oil sump and pull it back.

Attention: If you cannot drag the crankcase, then remove those rods from the stabilizer bar on the left and right and lower the rear axle beam even more.

Installation

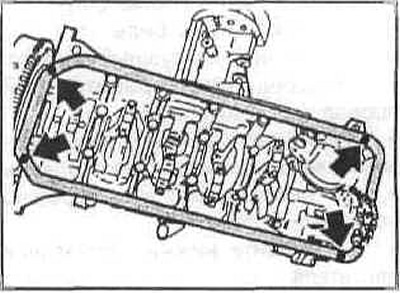

Clean the mating surfaces of the oil sump and cylinder block.

Lubricate the joints on the sprocket housing cover and on the cover with an elastic sealant. The sealant layer should be about 3mm wide and 2mm high.

Lubricate the new oil pan gasket and check for proper seating.

Caution: The gasket must always be replaced.

Install the oil pan.

Install the crankcase bolts, but do not tighten them yet. Tighten the bolts on the gearbox first, then on the engine. Finally, tighten the bolts to a torque of 10 Nm, i.e. not much. If you overtighten the bolts, the gasket will pinch and become loose.

If so, insert the oil lines into the mounts on the crankcase. Insert the dipstick guide tube together with the O-ring and secure with the bolt. A damaged O-ring must always be replaced.

Attach the oil return hose from the oil separator to the dipstick guide tube and secure it with a clamp.

Wind up and fasten the plug of the oil level sensor.

Install and secure the anti-roll bars.

Raise the front axle beam and secure it with bolts.

Connect the steering shaft to the steering gear (lath). Tighten the clamping bolt to 20 Nm.

Lower the engine, remove the lift. Tighten fasteners both engine mounts with a torque of 6m.

Attention: The following tightening torques are used for tightening the nuts/bolts and motor mounts: parts with M8 thread are tightened with a torque of 25 Nm, and with M40 threads with a torque of 45 Nm.

Install the power steering pump.

Fill the engine with oil. There are two marks on the dipstick that indicate the amount of oil in the engine. The difference between the minimum and maximum levels corresponds to 1 liter. Lower the car. Install the air filter. Connect the negative cable to the battery.

After the test run, check the oil sump for tightness and, if necessary, tighten the bolts carefully.

Install the lower engine mudguard.