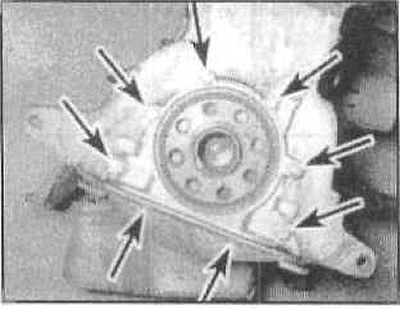

Remove the bolts and/or nuts securing the stuffing box to the engine block. Don't forget to remove the two bolts (from below), connecting the back of the oil sump to the base of the stuffing box.

Pass a sharp, thin knife between the crankcase gasket and the stuffing box. Be very careful not to damage or contaminate the gasket so that it can be reused.

Tap the body with a plastic mallet or piece of wood. Do not pry the housing away from the engine block with a screwdriver as this may damage the contact surfaces.

Using a scraper, remove all traces of old sealant from the contact surfaces of the housing and engine block and wipe them with a rag moistened with solvent.

Caution: Be very careful not to scratch the soft aluminum surfaces.

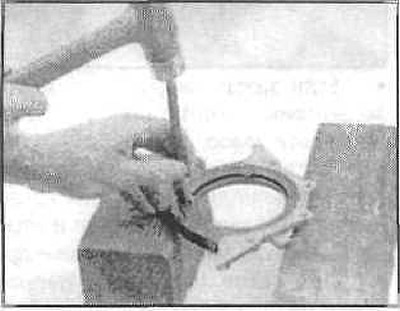

Place the housing on two pieces of wood and knock out the oil seal with a hammer and screwdriver.

Be very careful not to damage the walls of the gland mounting hole.

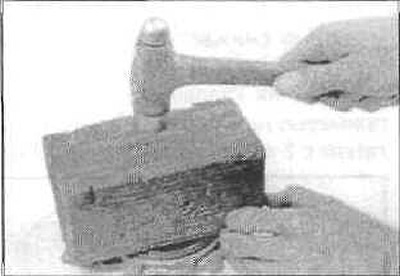

Coat the outer edge and sealing lip of the new oil seal with multipurpose grease and drive the oil seal into the housing using a hammer and block of wood.

Apply a thin coat of special sealant to the oil pan gasket where it contacts the oil seal housing. Apply additional sealant to the edges of the gasket adjacent to the engine block.

Coat both sides of the new gasket with sealant, then apply it to the stuffing box. Mount the housing on the back of the motor, insert the bolts and tighten to the correct torque. Work in a diagonal sequence.

Attention: First tighten the bolts securing the housing to the engine block, then the bolts securing it to the oil sump.

Install flywheel/drive. Install the gearbox.