Attention: The DDE control unit is equipped with a fault code memory that stores fault codes for the electrical part of the fuel injection system. In a specialized workshop, you can read the fault codes using a diagnostic tool, and then erase them from the memory.

Checking glow plugs

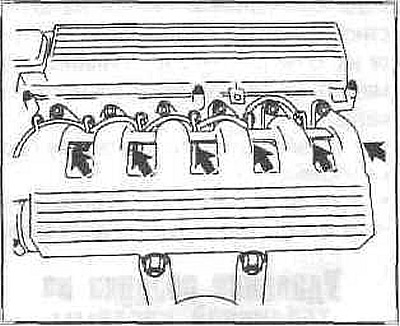

Remove the engine covers and the charge air pipe above the glow plugs.

The spark plugs are under the intake ports.

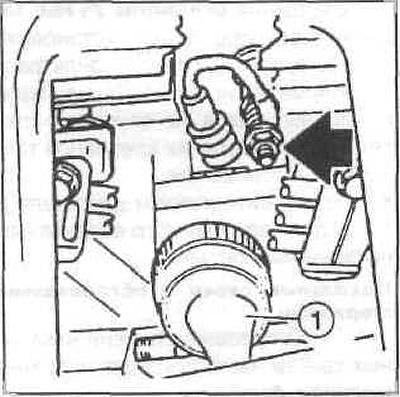

Loosen the nut and disconnect the wire from the glow plug.

Connect a voltage tester to the positive voltage point on the intake manifold, and connect the other wire to each glow plug in turn. The probe LED lights up: the glow plugs are good. For an accurate check, check the current drawn with an ammeter (In workshop).

LED does not light up, glow plug is defective, replace it.

Withdrawal

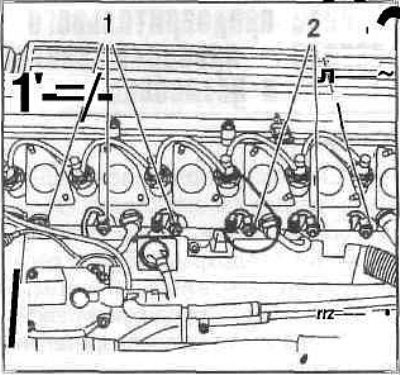

Remove the intake manifold.

Disconnect the wires (1) And (2), unscrew the glow plugs and check them visually.

Installation

Lubricate the threads of the glow plugs with high temperature copper based paste. Screw in glow plugs. The tightening torque is

Attention: The tightening torque must not be exceeded, otherwise the O-ring between the glow plug and the threaded part may be deformed.

Connect the wires to the glow plugs and tighten the nuts to 5 Nm.

Install the intake manifold on the block head and tighten its fastening nuts to a torque of 25 Nm, replace all gaskets. Install the oil filter housing support and the exhaust gas recirculation pipe to the intake manifold and tighten them also to 25 Nm.

Install the engine shrouds and charge air pipe over the glow plugs.

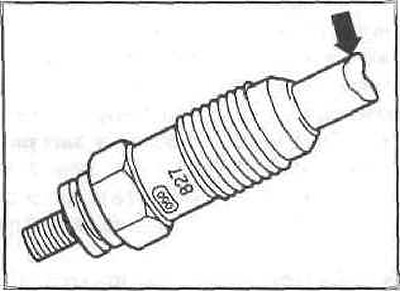

Glow plugs with burnt stems

Burnt glow plug rods often lead to injector damage.

If such glow plugs are found during diagnostics (arrow), it is not enough just to replace them. It is necessary to check the nozzles for the shape of the jet, uniformity, pressure and density in the workshop.