Checking the vacuum brake booster

The brake booster should be tested for function if the brake pedal force required to stop the vehicle is unusually high.

With the engine off, firmly depress the brake pedal at least 10 times, and then start the engine with the pedal depressed. The pedal should drop slightly under the force of the foot. In this case, the brake booster works normally.

If not, unscrew the vacuum hose from the brake booster. Start the engine. Putting your finger on the end of the vacuum hose, check if there is a vacuum (underpressure).

If there is no vacuum: check the vacuum hose for leaks and damage, replace if necessary. Tighten all clamps firmly.

Diesel engine: Pull the vacuum hose off the vacuum pump and check if there is vacuum at the hose connection.

If there is vacuum: measure it, if necessary, have the brake booster replaced by a workshop.

Attention: When doing this, always replace the non-return valve in the vacuum hose, as the diaphragm in the brake booster can be damaged due to incoming fuel vapors (for a gasoline engine and a faulty check valve). The arrow on the check valve must point towards the intake manifold.

Hydraulic brake booster - check, removal and installation

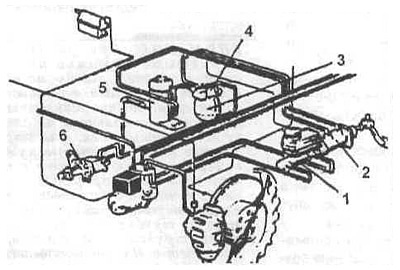

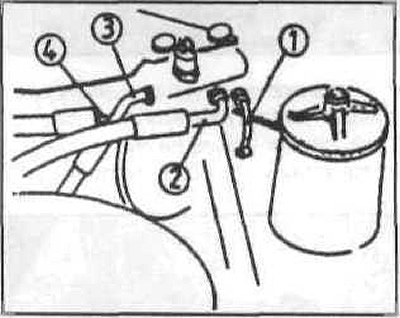

Elements of the brake system with hydraulic brake booster

1 — the main brake cylinder;

2 - brake booster;

3 - hydraulic accumulator;

4 - DS battery;

5 - expansion tank;

6 - booster pump.

With the engine off, press the brake pedal 20 times.

While holding the pedal, start the engine.

If the pedal goes down, the system is OK. If the pedal does not go down, there may be the following problems:

- the pump is faulty;

- defective DS controller;

- faulty hydraulic accumulator;

- brake booster defective.

Checking the hydraulic part

Empty the accumulator - press the brake pedal 20 times.

Disconnect the cable from the switch and remove the DS controller.

Install the connecting element in place of the switch.

Connect a pressure gauge to the connecting element, close both valves.

Checking the tightness of the DS controller and the brake booster

Start the engine while watching the pressure gauge.

After reaching the upper overpressure, stop the engine.

If the pressure drops by more than 5 bar within 5 minutes, loosen the return line on the DS controller.

If oil appears in the return line to the DS controller, the DS controller is leaking and must be replaced.

If no oil comes out and the pressure drops, the cause is an internal leak in the brake booster, which should be replaced.

Checking the operation of the accumulator

Release the pressure in the accumulator by depressing the brake pedal 20 times - the pressure gauge is at 0.

Start the engine and watch the pressure gauge.

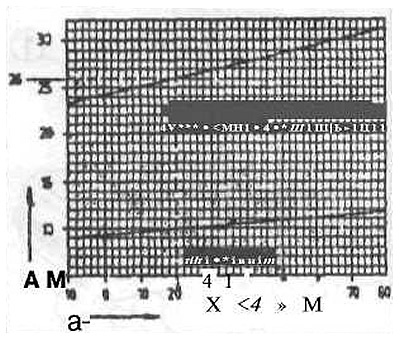

The pressure gauge should read according to the chart below. If this value is not reached or exceeded, the accumulator must be replaced.

Pressure chart

A is the gas filling pressure;

B is the temperature of the accumulator,°С.

Checking the operation of the DS controller

Start the engine. The pressure will rise to the overpressure cut-off value.

Reduce accumulator pressure (by pressure gauge) to the cut-in pressure by depressing the brake pedal while the engine is running.

The DS controller will then switch on again for «battery charging». The pressure will rise again.

If the test value is not reached, the DS controller must be replaced.

Working pressure 130 bar.

Upper switching pressure 52-57 bar.

Lower switching pressure 36-41 bar.

Release accumulator pressure by depressing the brake pedal 20 times.

Remove the test pressure gauge, remove the connector and install the switch.

Plug in the cable.

Check and top up the oil level.

Checking the operation of the brake booster / brake master cylinder

Remove the air outlet bolt on one brake caliper.

Connect a pressure gauge and bleed air.

Attach a pedal force gauge to the brake pedal. Engine running (full hydraulic accumulator) load the brake pedal with a force of 200 N. In this case, the pressure gauge should show a pressure of 70-90 bar.

If the pressure is not reached and the rest of the system is OK, the brake booster should be replaced.

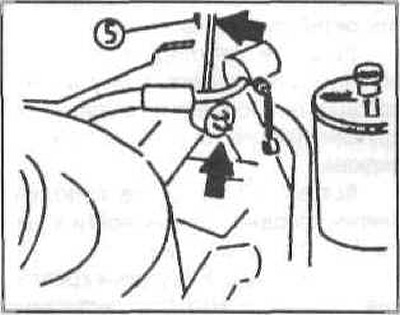

Removing the brake booster

Press the brake pedal 20 times (empty the accumulator).

Remove the brake fluid from the expansion tank.

Remove left lower instrument panel trim.

Disconnect the brake pedal spring. Separate the pedal-brake device connection.

Disconnect the compensation tank from the brake cylinder and plug it immediately. Avoid any pollution.

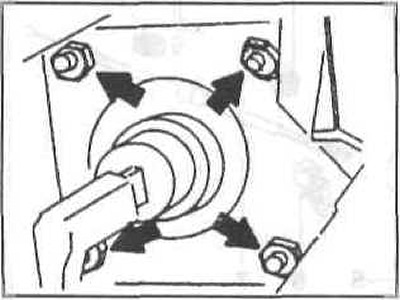

Disconnect the brake booster from the arm support.

Installation is carried out in reverse order.

Brake booster replacement

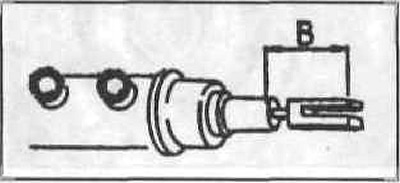

Disconnect the brake booster from the cylinder.

Determine the B dimension on the amplifier and remove the plug.

Install the fork on the new brake booster, keeping dimension B.

Removal and installation of the DS-regulator

Clear the environment of the DS controller.

Empty the accumulator by applying the brakes 20 times.

Disconnect the cable from the bypass pressure switch.

Unplug and plug immediately:

- pipeline DS regulator to the tank;

- pipeline (2) from DS controller to steering gear;

- pipeline (3) from the DS controller to the pump;

- pipeline (4) from the DS controller to the brake booster.

Attention: Due to solid particles of dirt, the operation of the DS-controller may be disturbed, which can lead to failure of the brake and power steering. Therefore, make sure that pipes and hoses are free from contamination.

When installing, the pipelines should be tightened with a torque wrench, observing the tightening torque.

Remove air from the system.