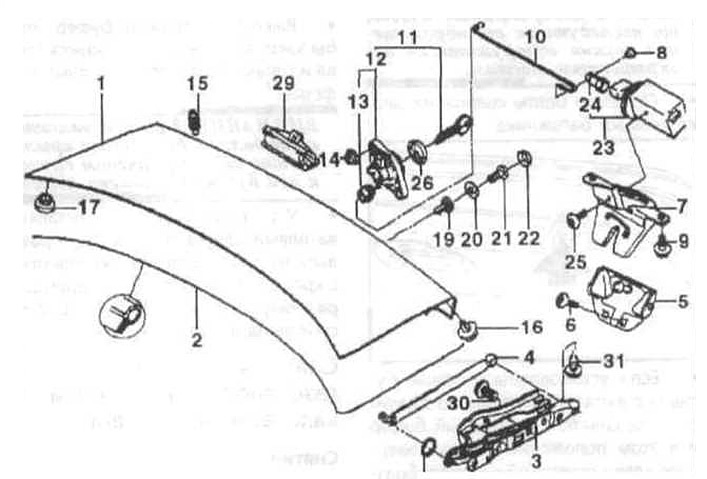

1 - trunk lid;

2 - seal;

3 - loop;

4 - gas-filled rack;

5 - lock latch;

6 - TORX bolt with washer;

7 - lock;

8 - sleeve;

9 - TORX bolt with washer;

10 - connecting rod;

11 - lock with a key;

12 - constipation with a code;

13 - rod mount;

14 - lock nut;

15 - thrust buffer with ejector;

16 - thrust buffer;

17 - rubber stopper;

18 - fastening washer;

19 - inserted nut;

20 - adjusting washer;

21 - self-tapping bolt;

22 - protective cap;

23 - actuator;

24 - connecting piece;

25 - TORX bolt for plastic;

26 - gasket;

27 - emphasis;

28 - buffer;

29 - key;

30, 31 - TORX bolt with washer.

Withdrawal

Remove the cover.

Pull the wiring harness out of the trunk lid. To do this, disconnect the plugs from the license plate lights and central locking. Tie a rope to the plugs and pull out the wire harness.

Attention: The rope remains in the trunk lid and serves to secure the installation.

Mark the position of the hinged trunk lid by tracing the plate with a felt-tip pen.

Support the trunk lid securely or have an assistant hold it.

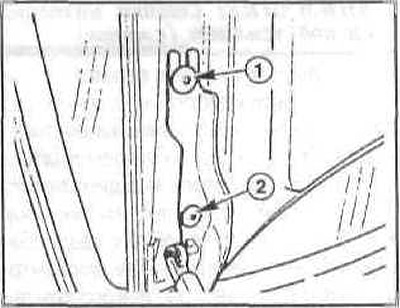

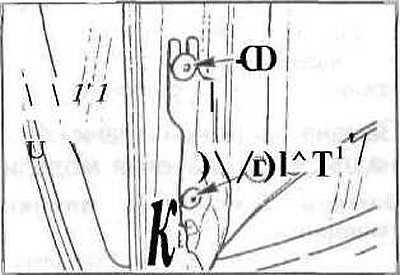

Loosen left and right bolts (1), unscrew the bolts (2).

Remove the trunk lid together with an assistant.

Installation

Put the trunk lid together with an assistant. Tighten the bolts (1), without tightening them.

Align the trunk lid in accordance with the marks made during removal. If the trunk lid is being replaced, adjust it position.

Insert the electric wires for the license plate light and for the central locking with a rope into the trunk lid and secure them.

Fix facing, replace the damaged clips. Trunk lid adjustment

Attention: Since the trunk lid is adjustable and mounted in an unpainted body, subsequent movements of the trunk can be detected as painted.

Loosen the trunk lid lock bolts.

If stop buffers with ejectors are installed, press the ejector into the stop buffer and in this position turn slightly to the left with a Phillips screwdriver. Due to this, the ejectors will be blocked in the stop buffers.

Unscrew the stop buffer.

Attention: Secure the trunk lid with the gas strut removed so that it does not fall.

Remove gas strut

Loosen left and right bolts.

Loosen the fasteners of the lower part of the trunk lid lock so that it can move in height. To do this, pry up the shield in the rear lining of the trunk.

Carefully close the trunk lid and move it sideways so that the gap to the right and left fenders is the same and runs parallel (allowable spread±1 mm).

Carefully open the trunk lid.

Tighten the fasteners on the bottom of the lock.

Close the trunk lid and check the adjustment, repeat if necessary.

Open the trunk lid.

Check for faults on the sliding parts at the bottom of the trunk lid lock, replace if necessary.

Close the trunk lid.

Check the height of the trunk lid relative to the rear fenders. She should be level with the wings (tolerance±1 mm).

Check adjustment, repeat if necessary.

Open the trunk lid.

Unscrew the stop buffer so that the closed trunk lid on the left and right rests on the stop buffers.

Attention: The trunk lid must not be higher than the fenders, otherwise.

For stop buffers with ejectors, turn the ejector slightly to the right using a Phillips screwdriver. Due to this, the persistent buffer will be released and come out.

Removal and installation of a gas-filled rack of a cowl/trunk lid

Withdrawal

Open the lid (hood).

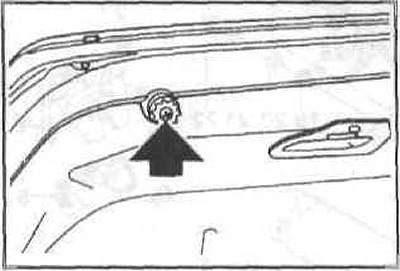

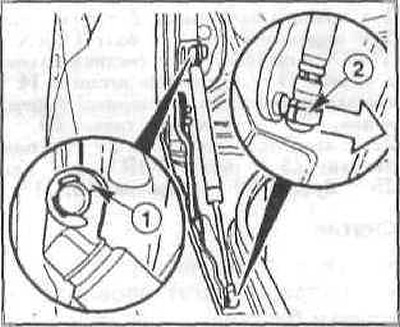

Trunk lid: press the top fastening washer to the side (1).

Pry off the spring clip with a screwdriver.

Wring out a rack below from a spherical head.

Attention: the stand is under stress (compressed).

Installation

Press the gas-filled strut onto the ball head, first inserting the mounting bracket from the end into the groove. Press the stand onto the ball head and press the mounting bracket upwards with a screwdriver.

Put the stand on your finger and secure with the fastening spring.

Replacing the protective bar / model designation lettering

Protective bar replacement (molding)

The protective strips are fixed with plastic expanding brackets on the body parts.

Pull the bar off by hand or pry it off with a wide plastic spatula.

As a rule, when removing the bar, the plastic bushings are pulled out along with the brackets. Therefore, remove the bushings from the pins and insert them into the holes of the body parts.

Straighten bent strips before installation.

Then install the protective strips with staples over the corresponding holes and push them in. If necessary, hammer the pins with fist blows.

Replacing the inscription with the model designation

Divide the adhesive joint between the decal and the bodywork with a thin nylon string (fishing line) and remove the caption. To facilitate the work, lubricate the fishing line (cord) liquid detergent and wind the ends of the fishing line around the wooden blocks. Lightly heat the lettering with a hair dryer.

Remove adhesive residue with alcohol or a special compound.

Heat the new lettering to about 50°C with a hair dryer, remove the protective paper, align the lettering and press it against the body for about 10 seconds.

BMW emblem replacement

Pry off the BMW emblem by placing a cloth under it to protect the paintwork.

Apply a non-hardening sealant to the back of the badge for better adhesion.