Withdrawal

Raise the car.

Remove the complete exhaust system.

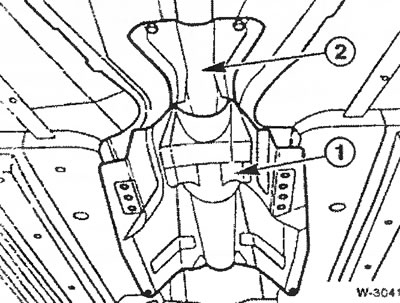

Remove the heat shields -1- and -2- from the bottom of the vehicle.

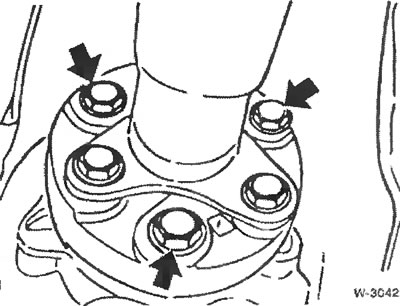

Unbolt the disc joint at the gearbox. To prevent the cardan shaft from turning, it must be held with a band wrench.

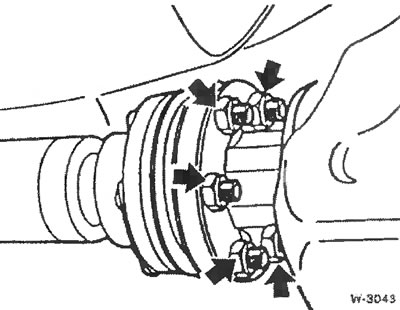

Loosen the propshaft mounting nuts at the final drive.

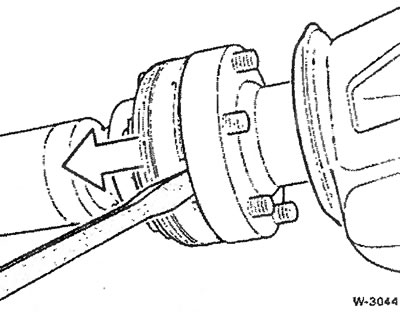

In the groove area, use a screwdriver to press the cardan joint of equal angular velocities from the flange.

Attention: Do not allow the cardan shaft to fall on the hinges. In this case, especially at the cardan joint of equal angular velocities, the rubber cuff is squeezed.

While holding the intermediate bearing, unscrew the fastening nuts.

Pull the cardan shaft down at the intermediate bearing and remove it from the dowel pin at the gearbox.

Note: Protect the CV joint against dirt with a transport cover or plastic bag.

Installation

If there are vibrations and noises coming from the cardan shaft, you can check its balance in the workshop. In addition, you should make sure that the hinges are working.

Attention: Cardan shafts are balanced as an assembly, so they can only be replaced as a set. Worn cardan shafts must be replaced.

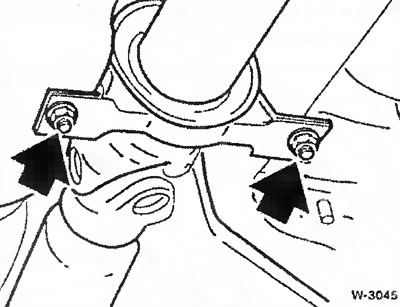

If the disc joint is worn, it must be replaced by loosening the bolts -arrows-. Install the new disc joint so that the arrows marked on the perimeter point towards the respective flange lugs.

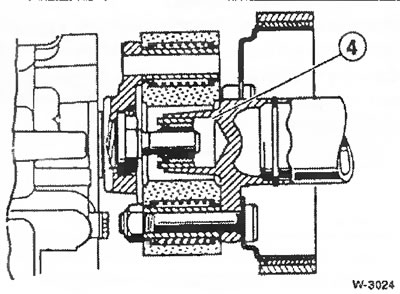

Before installing, check alignment of propshaft -4- at disc joint. If necessary, lubricate centering parts with Molykote Longtherm 2 grease. Replace damaged centering parts.

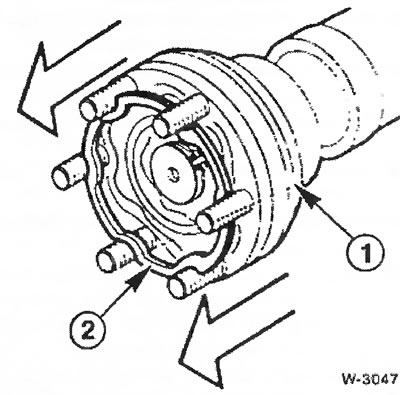

Pull out universal joint -1- as far as it will go. If the grease has been wiped off, it is necessary to replenish the joint with grease prescribed by BMW.

Replace seal -2-. Clean the pre-sealing surfaces of the CV joint and the flange from grease with a cloth soaked in alcohol.

Push the cardan shaft with the cardan joint extended from it onto the flange at the final drive.

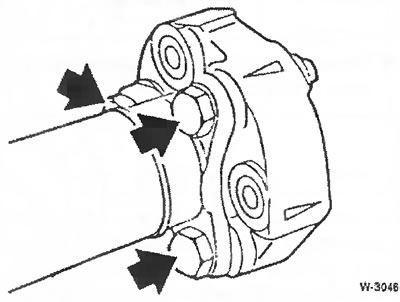

Attention: During installation, the cardan joint must not slide onto the cardan shaft, as in this case, the grease can squeeze out the sealing gasket, as a result of which the tightness of the hinge will not be ensured. By pressing from all sides around the perimeter on the cardan joint, evenly tighten the cardan shaft to the final drive flange. Use new self-locking nuts, tighten fastening to 70 Nm.

Bolt disc joint to gearbox flange. Tightening torques for mounting bolts: M8 - 45 Nm; M10 - 70 Nm; M12 - 80 Nm.

Tighten intermediate bearing bracket to 22 Nm.

Screw on the heat shields of the exhaust system

Install exhaust system.

Lower the car.