To check, a compression tester is required, which is offered quite inexpensively in specialized stores for gasoline engines.

Attention: For diesel engines, a compression gauge with an extended measuring range is required.

The greatest information gives the pressure difference in individual cylinders. It must not exceed 1.5 bar. If one or more cylinders have a pressure that differs from the pressure in other cylinders by more than 1.5 bar, this indicates a valve defect, worn piston rings or cylinder working surfaces. If the wear has reached the limit value, the engine must be repaired or replaced.

For gasoline engines, it is necessary to turn out the spark plugs; this work operation is recommended to be combined with the scheduled replacement of the spark plugs. In a diesel engine, the glow plugs are turned out to check the compression.

The value of the displayed compression pressure is indirect, since it, among other things, depends on the device used. This value must be at least 10 bar for petrol engines and at least 20 bar for diesel engines.

A prerequisite for testing is a charged battery.

To check the compression, the gasoline engine must be warmed up to operating temperature, and the diesel engine must be cold.

Gas engine

Warm up the engine while driving until the coolant temperature gauge shows normal operating temperature. Stop the engine, turn off the ignition.

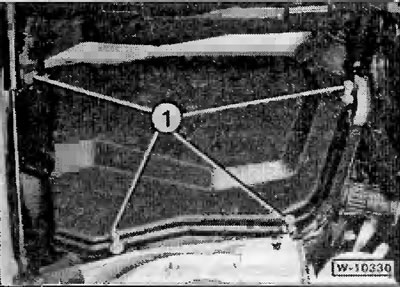

Remove the air microfilter housing located on the right in the engine compartment in order to gain access to the electronics unit.

Unscrew fasteners -arrows- and remove electronics cover.

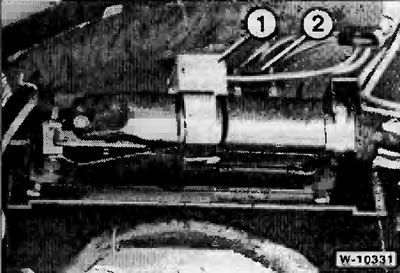

To exclude fuel injection during the test, remove the main relay -1- of the DME system (electronic digital engine management system), -2- DME system fuses.

Remove all spark plugs, see section "Maintenance work".

Attention: The transmission must be in neutral and the handbrake applied. Turn the engine crankshaft a couple of cuts with a starter to throw carbon and soot out of the cylinder.

Press or screw the compression tester into the spark plug hole in accordance with the operating instructions.

Ask an assistant to press the accelerator pedal all the way down and hold it with your foot during the entire check.

Rotate the engine about 8 revolutions until the pointer on the compression gauge no longer indicates an increase in pressure.

Check all cylinders one by one and compare the obtained pressures with the prescribed values.

Then install the spark plugs, see section "Maintenance work".

Replace the main relay, close the electronics box with a cover.

Install the microfilter housing to clean the air entering the passenger compartment.

Diesel engine

Remove the air microfilter housing located on the right in the engine compartment in order to gain access to the electronics unit.

Remove the cover of the electronics box.

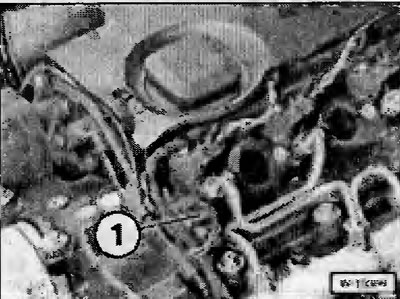

520d, 530d: To prevent the engine from starting, unplug the connector -1- for the camshaft pulse sender.

525tde: Remove the preheating relay. For parts location, see p. 60.

Unscrew the electrical cable from the glow plugs and unscrew the glow plugs with a suitable socket wrench.

Screw in the compression gauge instead of the glow plug.

Turn the engine shaft with a starter until the arrow on the compression gauge scale stops showing an increase in pressure. Record the measured pressure value. Check all cylinders one by one.

After checking, screw in the glow plugs and tighten to 25 Nm. Pretreat the threads of the glow plugs with CRC high temperature copper grease available from a BMW workshop.

Tighten the electrical cable to the glow plugs to 5 Nm.

Insert the relay for the preheating system.

Close the cover of the electronics box. Install the microfilter housing to clean the air entering the passenger compartment.