Always use a torque wrench to tighten the wheel bolts. This ensures that the wheel bolts are evenly and firmly tightened.

Attention: When changing and removing tubeless tires, for safety reasons, it is imperative to replace the valve with a rubberized body.

Loosen the wheel bolts when the vehicle is on the ground with all wheels. To prevent the car from rolling, apply the handbrake or engage first gear.

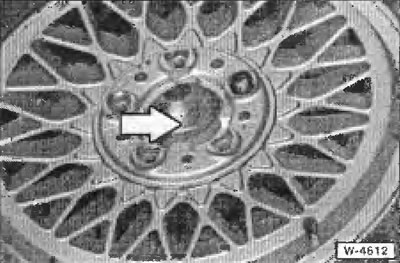

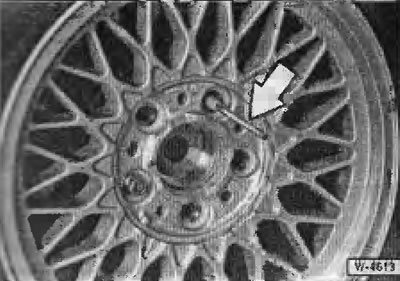

On lockable wheel bolts, use a screwdriver to pry off the protective caps. Insert the key into the lock of the bolt until it stops, while the key slot is parallel to the oval recess. Turn the key by 90°and remove it together with the locking piece. Installation is carried out in the reverse order. When removing the key, the sleeve must be pressed against the wheel bolt. Put on the protective cap.

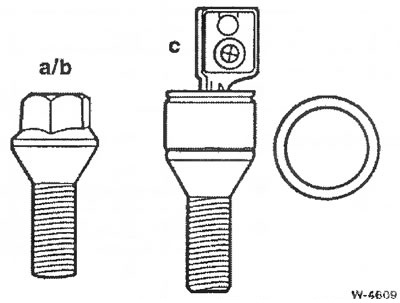

- a/b - galvanized / black chrome plated wheel bolt;

- c - lockable wheel bolt, black chrome plated.

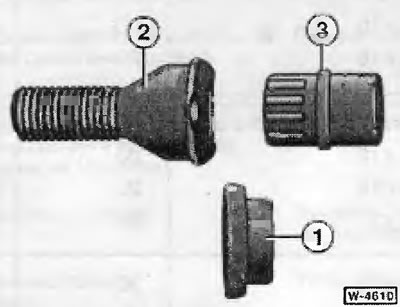

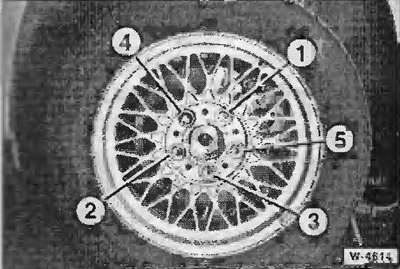

If available, remove anti-tightening tool as follows: cap -1- can be easily turned to the left with a wheel bolt wrench and removed. Then insert the adapter -3- into the wheel bolt -2- and unscrew the wheel bolt.

Attention: The adapter -3- must be included in the on-board tool kit.

Raise the car.

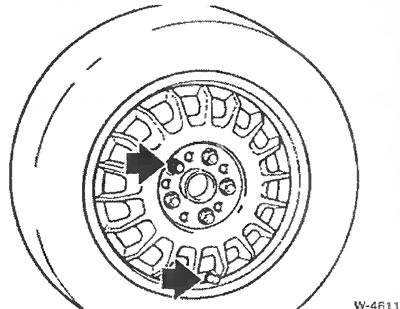

Turn the wheel so that the valve -lower arrow- is at the bottom.

Before removing the mutual position of the wheel disk and the hub, mark with a felt-tip pen so that the balanced wheel can be installed in the same position during assembly.

Attention: Depending on the design of the disc wheel, different wheel bolts are used. Be sure to use only bolts specified by BMW.

When fitting light alloy disc wheels other than original BMW wheels, the appropriate wheel bolts must also be used instead of BMW wheel bolts. It is recommended to include the appropriate BMW spare wheel bolts in the on-board tool kit.

Light alloy rims are protected against corrosion by clear varnish. When changing wheels, make sure not to damage the protective layer, otherwise restore the protective coating.

Before each installation of the wheel, clean the place of centering of the wheel disk on the hub and the contact surface of the wheel disk from dirt and oil deposits. Apply a thin film of rolling bearing grease to the centering point.

Clean dirty bolts. Replace bolts with damaged threads or rust. Do not lubricate the threads of the wheel bolts.

Before installing the disk wheel, insert the mounting plate provided in the on-board tool kit into the upper threaded hole for the wheel bolt. After screwing in a few wheel bolts, remove the mounting pin.

Tighten the wheel bolts crosswise in several steps. The tightening torque for all wheel bolts is 100 Nm.

Attention: If the wheel bolts are tightened one-sidedly or unevenly, increased stresses can occur in the wheel and/or wheel hub. If new disc wheels are installed, after driving 1000 km, tighten the wheel bolts to the specified tightening torque.