Withdrawal

1. Block the front wheels, then jack up the rear of the vehicle and place it securely on axle stands. Remove the exhaust system (see chapter Exhaust system). Remove the exhaust system heat shield.

2. At the sliding sleeve, loosen the clamping sleeve (if provided) a few turns, but do not remove it.

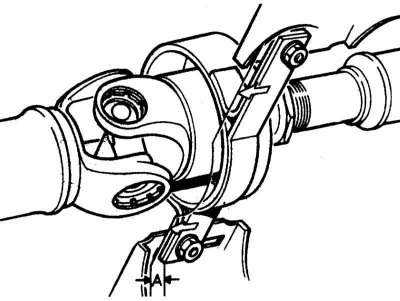

3. Latest models are not equipped with clamping sleeve. Apply paint, center punch or scriber to mark the alignment on the transmission flange and flexible coupling (or front universal joint on some models), as well as on the rear universal joint and the input flange of the differential, in order to be able to install the transmission in its previous position during assembly...

...and also on the rear universal joint and differential input flange

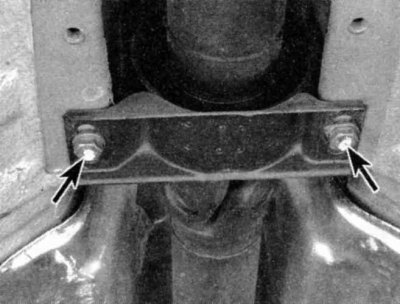

4. Give bolts and nuts of fastening of an elastic coupling (see illustration) or cardan joint (see illustration above) to the output flange of the transmission. Do not separate the cardan shaft from the flange yet.

5. On models with CV joints, first use a suitable jack to support the transmission. Loosen the mounting nuts and bolts of the rear transmission support (see chapter Manual gearbox (RKPP)), then move the support back and give the six nuts and bolts securing the CV joint to the transmission support. Give nuts and bolts on the rear flange of the cardan shaft (see illustration above).

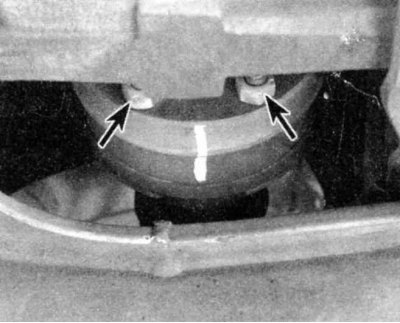

6. Support the cardan shaft at the central bearing and give the bolts (indicated by arrows) on bearing assembly

7. Tilt the driveshaft down at the center bearing, then remove it from the center pin on the transmission flange - remove the splined sleeve as well if more space is needed, but do not separate the driveshaft sections.

On vibration damper models, rotate the damper assembly 60°before removing it from the center pin on the transmission flange.

8. If you are going to clean the splined coupling or replace the rubber bush, mark both sections of the propeller shaft before separating the coupling. After cleaning the splines before reassembly, lubricate them with molybdenum disulphide grease. If you divided the cardan shaft sections without marking them, assemble the splined coupling so that the cardan joints are in the same plane. If the cardan shaft vibrates after installation, then you have installed its sections incorrectly. In this case, remove the cardan shaft, separate it at the splined coupling, and rotate one section 180°before installation.

Installation

Installation basically repeats the removal procedure in reverse order. However, you need to pay attention to the points listed below.

1. Apply a thin coat of molybdenum disulphide grease to the center pin on the transmission flange.

2. Position the driveshaft against the differential input flange first, slide it onto the center pin on the transmission flange, then place the center bearing against the pin and loosely screw in the mounting bolts. Where CV joints are installed, make sure that the gaskets are in working order, otherwise replace. Align the marks made during removal on the rear universal joint flange and differential input flange. Install the rear driveshaft section into the differential input flange with NEW self-locking nuts and tighten the nuts to the specified torque.

Do not reuse self-locking nuts.

3. Align the marks made during dismantling on the front of the driveshaft and connect the flexible coupling, universal joint or CV joint to the transmission output shaft using new self-locking nuts. Tighten the bolts to the required torque.

Here, different classes of bolts are used, which are tightened with different forces; the class of the bolt is marked on its head.

To avoid overloading the flexible coupling while tightening the bolts, hold the bolt with a wrench and tighten the nut on the flange side.

It will be easier to install the bolts on the flexible coupling by wrapping a large hose clamp around it and lightly tightening it, squeezing the coupling.

4. Preload the center bearing by moving it forward 4 ÷ 6 mm (for cardan shafts with sliding central element) or by 2 ÷ 4 mm (for shafts without sliding element) from its loose position, then tighten the mounting bolts to the required torque.

5. On models with a CV joint, move the rear transmission bracket forward and tighten the mounting bolts. Remove the jack from under the transmission.

6. Tighten the clamping sleeve on the spline.

7. Perform the rest of the installation procedure in the reverse order of removal.