All three transmission seals can be replaced without disassembling the transmission; two of them can be replaced even without removing the transmission.

If a seal is suspected to be leaking, carefully inspect the seals while working under the transmission. Install it on stands. Be sure to place chocks under the rear wheels to prevent the vehicle from rolling.

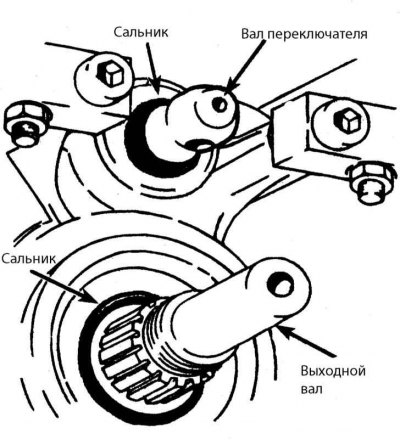

Don't confuse engine oil leaks with transmission leaks - hypoid oil, for example, has a peculiar odor and can be easily distinguished from engine oil. If oil coats the front of the driveshaft, either the switch shaft seal or the output shaft seal is leaking. If oil is found on the bottom of the clutch housing, then the input shaft oil seal is probably leaking (of course, the crankshaft rear oil seal can also cause engine oil in the bottom of the clutch housing). Whenever deciding to replace the oil seal, check the ventilation device at the top of the transmission case first. A clogged or damaged vent can cause the pressure inside the transmission to build up, causing the oil to be squeezed out through the seals. If you simply replace the stuffing box without clearing the clogged vent, the new stuffing box will soon lead to failure as well.

Output shaft seal

1. Raise the front of the car and place it on stands. Be sure to place chocks under the rear wheels to prevent the vehicle from rolling.

2. If necessary to provide access, remove the exhaust system (see chapter Supply system).

3. Remove the cardan shaft (see chapter transmission line). If measures are taken against creating a load on the cardan joints, then the cardan shaft can not be disconnected from the rear axle.

4. Bend the lock plate tabs out of their grooves and remove the lock plate. holding flange (if necessary, bolt the long plate), use a 30 mm thin wall socket to remove the flange nut. Remove the flange from the output shaft. Use a puller if necessary.

5. Use an oil seal remover or a small screwdriver to carefully pry out the old oil seal. Make sure the oil seal recess is not damaged when the oil seal is removed.

6. Lightly coat the lip of the new oil seal and clean the end of the output shaft. Place the stuffing box on the shaft and carefully install the stuffing box in place with a short piece of pipe with an outer diameter slightly smaller than the outer diameter of the stuffing box.

7. Install the flange. Apply sealant to the flange-facing side of the nut to prevent leakage. Tighten the flange nut to the torque specified in Table of sizes and adjustment data at the end of the Guide. Note that on Getrag transmissions the nut should be tightened in three steps. Thread compound must be applied to the threads on ZF transmissions. Install a new lock plate and bend its protrusions into the corresponding grooves.

8. Otherwise, installation is the reverse of removal.

Switch shaft seal

1. Follow steps 1-5 above.

2. On early models, to disengage the selector shaft from the selector shaft, remove the bushing retaining ring, then drive out the pin with a small punch.

3. On later models, to disengage the selector shaft from the selector shaft, shift into 3rd gear, pull back on the spring bushing and drive out the pin.

4. Use an oil seal remover or a small screwdriver to pry the oil seal (see picture). Make sure that when removing the oil seal, the oil seal recess will not be damaged.

5. Lubricate the collar of the new oil seal, then slide the oil seal onto the end of the switch shaft. Hammer the gland into place with a socket head or a piece of pipe of suitable dimensions.

6. Attach the switch stem to the switch shaft.

7. Install the flange (see above). The rest of the installation is the reverse of removal.

Input shaft seal

1. Remove the transmission (see Section Removal and installation of transmission).

2. Remove clutch release bearing and lever (see chapter Clutch).

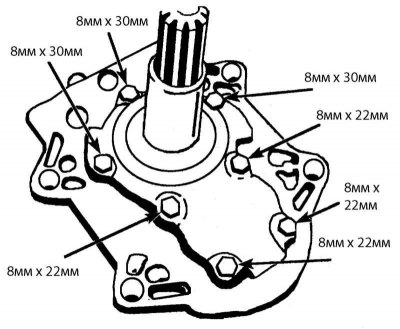

3. Remove the clutch guide bolts. On some models, the bolts are not the same size, so pay attention to the location of the bolts. Remove the clutch and all spacers underneath.

Guide Coupling Bolt Location (shown by arrows). Getrag 265 transmission shown.

4. Use an oil seal remover or screwdriver to remove the old oil seal. Do not damage the oil seal recess.

5. Lubricate the collar of the new oil seal and hammer it into place with a piece of pipe of suitable size. If applicable, replace the rubber o-ring in the coupling groove.

6. Clean the mounting bolts and sealing surfaces of the guide sleeve, as well as the bolt threads in the crankcase. On Getrag transmissions without an O-ring, apply a suitable sealant to the sealing surface of the guide sleeve. Install guide sleeve and spacer (spacers).

7. Apply sealant to the bolt shoulders, install the bolts and tighten them.

8. Otherwise, installation is the reverse of removal.

All seals

1. Check the gear oil level and add the recommended oil if necessary (see chapter Car maintenance).

2. Lower the vehicle, perform a proof test and check for leaks.