2. If the valves at this stage of the test seem satisfactory, measure the diameter of the valve stem at several points with a micrometer. Any noticeable difference in the meter reading is indicative of valve stem wear. If any of these conditions occur, the valve (valves) should be replaced.

3. If the valves are in good condition, they should be lapped into their respective seats to ensure tightness. If the seat has minor dents or has already been bored, these should be rubbed in with a fine polishing paste. Generally coarse polishing paste is not used unless the saddle has severe burns or deep dents. In such a case, the cylinder head and valves must be checked by a specialist in order to decide whether to bore the seat or even replace the valve or seat.

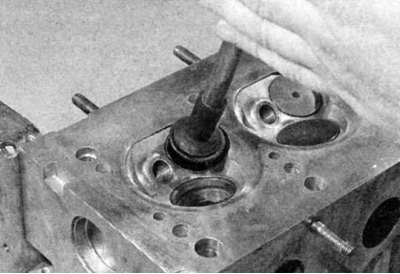

4. Lapping of valves is carried out as follows. Turn the head over and set it on a workbench, placing blocks of wood on both sides to provide clearance with the valve stems.

5. Apply a small amount of polishing paste of the appropriate grit to the valve seat bevel and attach the suction cup of the polishing tool to the valve head. Lap the valve head to the seat with a reciprocating-rotary motion, periodically lifting the valve to redistribute the polishing paste. Do not overdo it.

If a soft spring is installed under the valve head, then the lapping operation will be noticeably facilitated.

6. If a coarse polishing paste is used, then lapping until a smooth matte surface is achieved on the seat and valve, then remove the paste and repeat the process with a fine polishing paste. The lapping operation will be completed when the valve and seat have smooth, light gray matte surfaces without breaks. Do not lap the valves more than necessary.

7. After lapping all valves before assembling the cylinder head, thoroughly wash off all traces of lapping paste using kerosene or a suitable solvent.