If you don't have enough tools or don't want to do honing, most machine shops will do the job for a reasonable price.

1. Before honing the cylinders, install the main bearing caps and tighten the bolts to the torque given in Table of sizes and adjustment data at the end of the Guide.

2. Two kinds of hone are usually available: flexible hone or type "bottle brushes" and the most common grinding hone with spring-loaded abrasive stones. Both types of hon are suitable for this job, however, for the less experienced hon type mechanic "bottle brushes", might be easier to handle. You will also need several liters of kerosene or honing oil, rags and an electric drill. Proceed as follows.

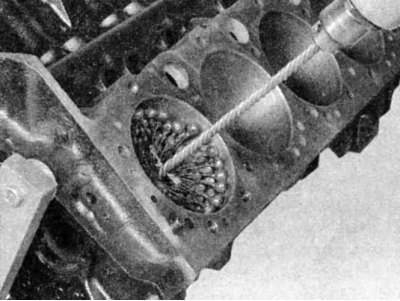

3. Install the hone in the drill, compress the stones into one bundle and insert the bundle into the first cylinder. Don't forget to wear safety goggles or a mask.

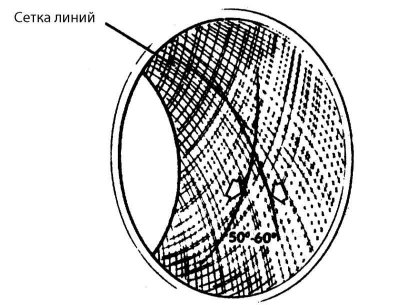

4. Lubricate the cylinder with sufficient honing oil, turn on the drill and move the honing tool up and down so that a fine network of intersecting lines forms on the cylinder wall. Ideally, the grid lines intersect at an angle of approximately 60°. Make sure there is enough lubrication and do not remove more material than is necessary to obtain the desired surface.

Piston ring manufacturers may set a smaller crossover angle than the usual 60°- read and follow the instructions provided with new rings.

5. Do not remove the hone while it is rotating from the cylinder. On the contrary, turn off the drill and continue to move the hon up and down until it stops completely, then compress the stones into one bundle and remove the hon. If hone type is used "bottle brushes", then turn off the drill and, removing the hone from the cylinder, rotate the chuck in the normal direction.

6. Remove oil from the cylinder and repeat the operation for the remaining cylinders.

7. After finishing honing with a small file, chamfer the upper edges of the cylinders so that the piston rings do not jam during installation. Be very careful not to scratch the cylinder walls with the end of the file.

8. The entire cylinder block must be washed again very thoroughly with warm, soapy water to remove the abrasive sand formed during honing.

Cylinders can be considered clean when a white, lint-free cloth soaked with clean motor oil, which is rubbed on the cylinder, no longer collects grit residue, leaving gray spots on the cloth. Do not forget to brush all the holes and channels of the oil lines with a brush and rinse them with running water.