General description

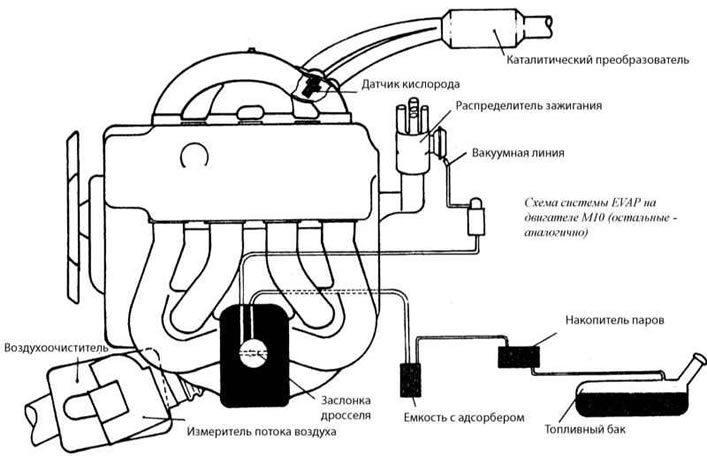

Diagram of the EVAP system on the M10 engine (the rest are the same)

This system is usually installed on vehicles equipped with a catalytic converter.

When the engine is turned off, the fuel in the fuel tank evaporates, creating vapor pressure. The gasoline vapor recovery system collects these vapors in a container with an adsorber. On the move, the vapor removal valve opens slightly and fuel vapors gradually enter the intake manifold and burn out. When starting a cold engine or when the engine is idling, the evaporative valve prevents vapors from entering the intake manifold and enriching the fuel mixture beyond measure.

There are two types of vapor removal valves: electrically operated and vacuum operated. To determine which valve your vehicle has, trace the hose from the canister container until you locate the valve. Some valves are installed on the inlet pipeline, others - near the adsorber tank. See if there is an electrical connector on the valve or if there is a vacuum line going to it.

A faulty EVAP system only affects the driving performance of the engine when it is warm. The EVAP system is not usually the cause of difficult cold starts or other problems on a cold engine.

Examination

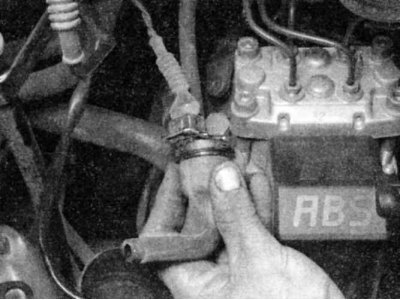

Vacuum Controlled Vapor Removal Valve

1. Disconnect the vacuum line from the valve and blow into the larger valve port. The valve must be closed and air must pass.

Some models have a thermal vacuum valve that prevents vapors from escaping until the coolant temperature reaches approximately 46°C. Test this valve to make sure it is vacuum operated at the correct temperature. The valve is usually located in the intake manifold near the temperature switch and coolant temperature sensor.

2. Disconnect a thin vacuum hose from the vapor removal valve and use a hand vacuum pump to create a vacuum at the valve inlet. The valve should open and allow air to pass through.

3. If the test is negative, replace the valve.

Electrically Operated Vapor Valve

1. Disconnect all lines from the valve (except for electrical connector) and move it to a convenient place for testing.

2. Check that the valve makes a click when the ignition is switched on.

3. If the valve does not make a click, disconnect the connector from the valve and check the power supply with a test lamp or voltmeter.

4. If battery voltage is present but the valve is not working, replace it. If there is no voltage, check the Motronic control unit and wires.

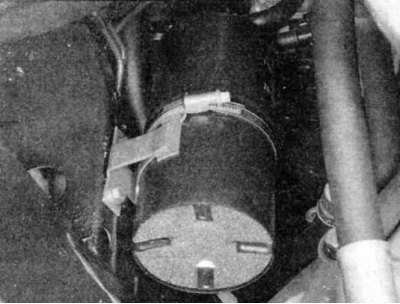

Container with adsorber

1. Mark the location of all hoses, then disconnect them from the container.

2. Slide the container out of the mounting collar. On some models it is necessary to loosen the clamp.

3. Visually inspect the container for leaks and damage.

4. If leaks or damage are found, replace container.