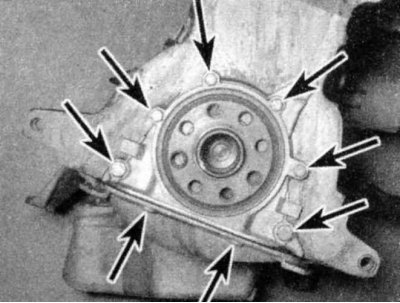

2. Give bolts and/or nuts of fastening of the holder of an epiploon to the block of cylinders. Don't forget to give two bolts (at the bottom) securing the rear of the oil pan to the bottom of the oil seal holder.

3. Pass a thin, sharp knife between the oil pan gasket and the front cover, thus separating the gasket from the cover. Be very careful not to damage or stain the gasket so that you can use it again later.

4. Destroy the gasket sealant between the holder and the cylinder block by tapping the cover with a rubber-faced hammer or an ordinary hammer, applying a wooden block. Do not poke anything between the cover and the block to avoid damaging the gasket surfaces.

5. Using a scraper, remove all traces of the old gasket material from the mating surfaces of the holder and cylinder block. There are commercially available, and may be useful, special solvents for removing gaskets. Once the gasket material has been completely removed, the gasket surfaces can be degreased by wiping them with a cloth soaked in a suitable solvent.

Be extremely careful not to damage or scratch the soft aluminum surfaces. Also, be careful not to damage or stain the oil pan gasket.

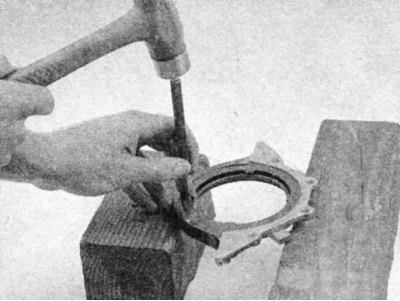

6. Support the holder with two pieces of wood and knock out the oil seal from the back with a hammer and screwdriver.

7. Be careful not to damage the gland hole during operation.

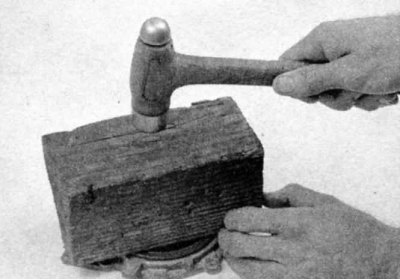

8. Coat the outside diameter and lip of the new oil seal with multipurpose grease and install the oil seal into the holder using a hammer and block of wood.

9. Apply a light coat of RTV type sealant to the oil pan gasket surface mating with the gland retainer. Apply more sealant to the edges where the gasket meets the cylinder block.

If the oil pan gasket is damaged, then instead of completely replacing the gasket, you can try cutting off the front of the gasket where it meets the cylinder block, then cutting off the front of the new gasket so that it is exactly the same size. Cover the inside of the sump with a piece of rag, then scrape off any traces of old gasket material from the mating surfaces. Attach a piece of new gasket to the pan with special adhesive, then apply RTV sealant as described at the beginning of this paragraph.

10. Lubricate both sides of the new gasket with RTV sealant, then connect the gasket to the gland retainer. Install the holder on the back of the engine, then fit the bolts and tighten them to the required torque. Tighten the bolts one by one in a crosswise pattern to do so evenly.

First tighten the bolts securing the holder to the cylinder block, then the bolts securing the oil pan to the cover. If the gasket is protruding over the lid-to-block connection or is wrinkling at the lid-to-sump connection, cut it to fit properly.

Once the RTV sealant has been applied, assembly must be completed within 10 minutes to allow the sealant to cure.

11. Install flywheel/drive plate (see Section Removal and installation of a flywheel/drive disk).

12. Install the transmission (for vehicles with manual transmission see chapter Manual gearbox (RKPP); for vehicles with automatic transmission, see chapter automatic transmission (AT)).