Mount the gearbox on stand 23.0.160 and drain the oil from it. Remove the front cover of the gearbox housing, being careful not to damage the adjusting rings (shown by arrows in the photo).

Remove the retaining ring, thrust washer and adjusting ring from the end of the input shaft.

Press the input shaft rear ball bearing out of the crankcase seat using puller 23.2.020, taking care not to damage the spacer sleeve.

Press the front ball bearing of the intermediate shaft out of the crankcase seat using puller 23.2.050.

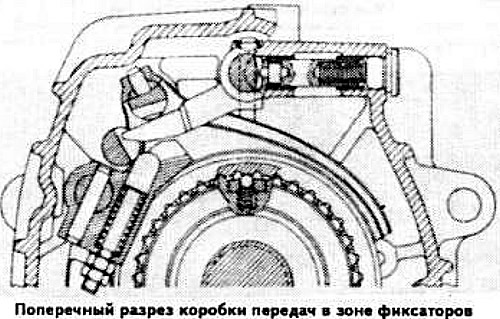

Unscrew cap 1 (see photo) the lock of the gear selection rod, remove the spring 2 and the blocking cracker 3.

Unscrew the reverse light switch being careful not to damage the gasket.

Remove the front part of the rear gearbox housing cover.

Remove primary and secondary shafts.

Disassemble the output shaft.

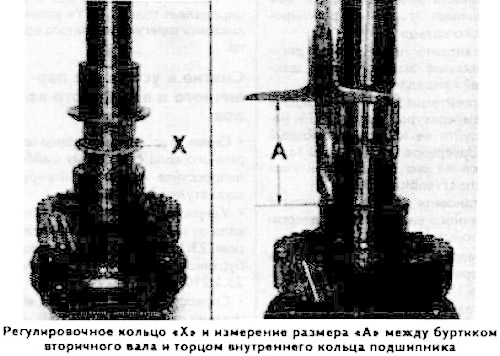

Determine the thickness of the adjusting ring «X» (see photo) in the following way:

Put on the secondary shaft:

- 3rd gear gear with needle bearing, 3rd gear synchronizer blocking ring, sliding clutch and synchronizer blocking ring;

- 2nd gear gear with a needle bearing, a shoulder sleeve and an inner bearing race, preheating the ring to a temperature of about 80°C.

Determine the distance «A» (see photo) between the shoulder of the output shaft and the end face of the inner ring of the bearing.

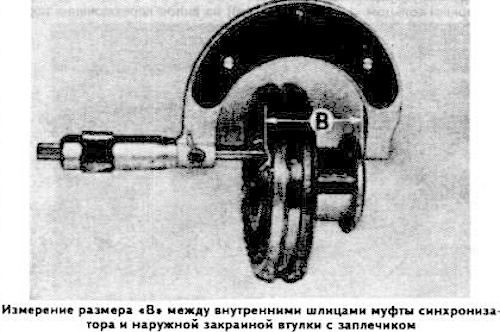

Determine the distance «IN» (see photo) between the inner splines of the sliding sleeve of the synchronizer and the outer flange of the sleeve with a shoulder.

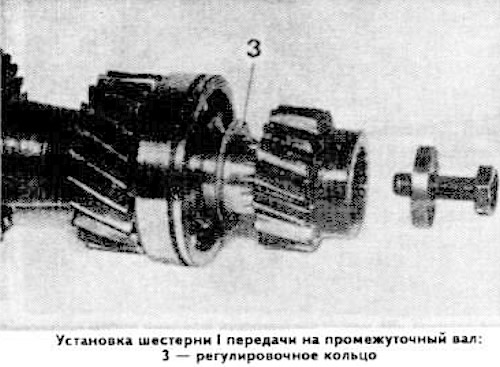

Remove bolt 1 (see photo), remove the washer 2, remove the 1st gear gear with two screwdrivers, taking care not to damage the adjusting ring 3.

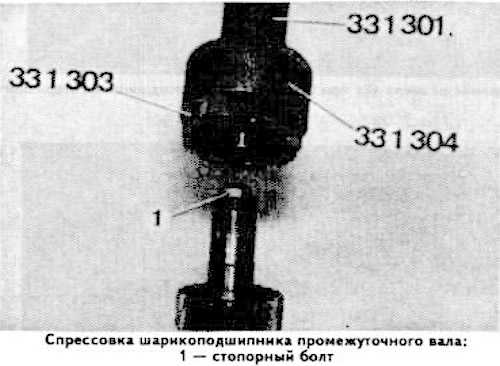

Press the ball bearing off the intermediate shaft using puller 33.1.301, removable cups 33.1.303 and ring 33.1.304.

Warning. To avoid damage to the thread of the bolt 1 (see photo) tighten it all the way.

Press a new bearing onto the intermediate shaft.

measure distance «WITH» between the end of the intermediate shaft and the end of the ball bearing.

Measure your height «D» gears of the 1st gear of the intermediate shaft.

Size difference «WITH» And «D» determines the thickness of the adjusting ring 3.

Install the selected adjusting ring in front of the 1st gear gear.

Heat the 1st gear gear to a temperature of about 80°C and press it onto the intermediate shaft. Screw the bolt into the end of the shaft, applying Loctite type glue to its threads «Frenbloc».

Install the output shaft ball bearing between the crankcase and support ring.

Measure the depth «E» crankcase socket, which should be equal to 13.1 mm.

Insert the ball bearing into the support ring.

measure distance «F» between the outer end of the bearing and the support ring.

Size difference «E» And «F» determines the thickness «Y» adjustable adjusting ring.