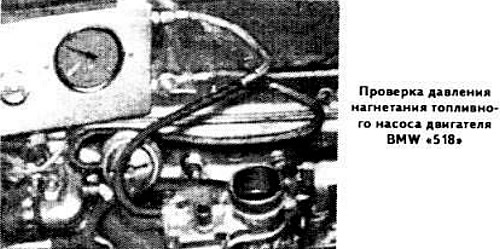

«518»

Connect the test fixture as shown in the photo. If the vacuum generated by the fuel pump is less than 0.5 kg/cm2, replace the pump.

With the engine off, pressurize the fuel system to 0.29-0.30 kg/cm2 by turning the knob of the control device. With the carburetor needle valve closed, the fuel pressure in the system should not drop.

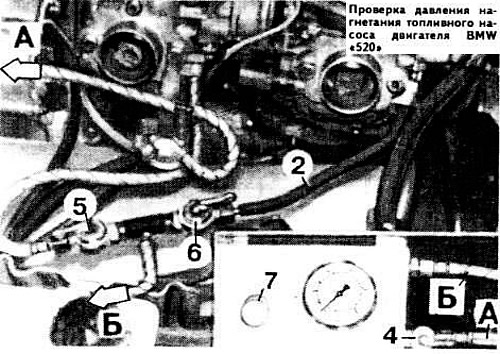

«520»

Connect the test fixture as shown in the photo. Start the engine, bring the engine speed to 4000 rpm and measure the fuel pump discharge pressure, which should be equal to 0.30 kg/cm2.

Close valve 4 and check the tightness of the needle valve of the front carburettor. With the engine off, use handle 7 of the tool to set the fuel pressure in the system within 0.29-0.30 kg/cm2. Close tap 6: the pressure must not drop.

Proceeding in the same way with valve 4 closed and valves 5 and 6 of the device open, set the fuel pressure in the system to 0.29-0.30 kg/cm2. Close valve 5 of the tool: if the needle valve of the rear carburetor is in good condition, the fuel pressure in the system does not drop.

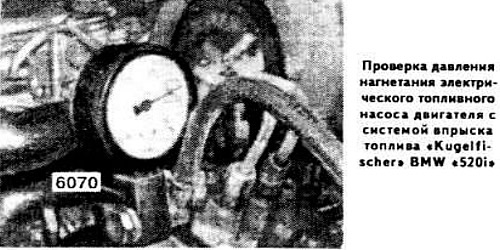

«520i»

Install the pressure gauge and bracket 6070 as shown in the photo. Switch on the ignition and read the pressure gauge, which should read 2 kg/cm2.

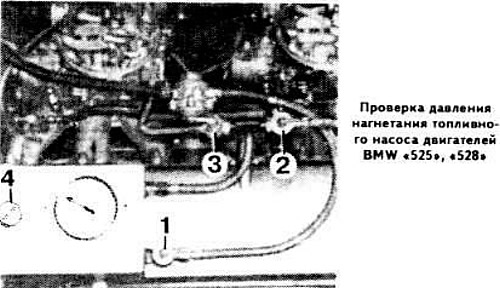

«525», «528»

Connect the control fixture as shown in the photo and open taps 1, 2, 3 of the fixture. Start the engine, bring the crankshaft speed to 4000 rpm and measure the fuel pump discharge pressure, which should be 0.21-0.25 kg / cm2.

With the engine off, check the front carburetor needle valve for leaks. Close valve 1 of the tool and use knob 4 to set the fuel pressure in the system to 0.29-0.30 kg/cm2, which should not fall after closing the needle valve.

Check the rear carburetor needle valve for leaks. Open valve 3 of the device, close valve 2, set the fuel pressure in the system to 0.29-0.30 kg / cm2. This pressure must not decrease after the needle valve is closed.