Fuel supply system

The constancy of the fuel level in each of the carburetor float chambers is ensured by adjusting the action of the floats on the needle valves. The preparation of the fuel-air mixture and the fuel consumption depend on the air pressure in the float chambers. In this regard, channels are made in the carburetor cover connecting the float chambers with the carburetor inlet, to which the pressure of the air purified in the air filter is supplied, i.e. the ventilation of the float chambers is closed. This achieves an almost constant composition of the fuel-air mixture, regardless of the degree of contamination of the air filter element. A shut-off valve is installed in front of the needle valve of the 2nd chamber, which opens and closes under the action of vacuum. This valve eliminates fuel leakage through the needle valve when the 2nd chamber is blocked at idle and at an average crankshaft speed.

Automatic starter

The enrichment of the combustible mixture required during cold start and engine warm-up is ensured by closing the air damper with an offset axis, the amount of fuel-air emulsion is adjusted by the throttle valve of the 1st chamber. An idle air jet with a movable needle simultaneously provides an enrichment of the combustible mixture at idle and in transient conditions. The needle of the jet is connected by a lever to the axis of the air damper.

The electronic idle control circuit compensates for the influence of intake air and coolant temperature, atmospheric pressure and engine load.

The microprocessor of the controller processes the input signals and controls the actuating motors of the servo drives of the air damper and the throttle damper of the 1st chamber.

The signals for correcting the filling of the cylinders are processed by the throttle valve of the 1st chamber, driven by an electro-pneumatic servo drive.

At the starting position (before turning on the ignition) automatic starter controller, sensors and choke servo are on, the choke rests on the needle of the idle air jet, the throttle valve of the 1st chamber is completely closed under the influence of the servo.

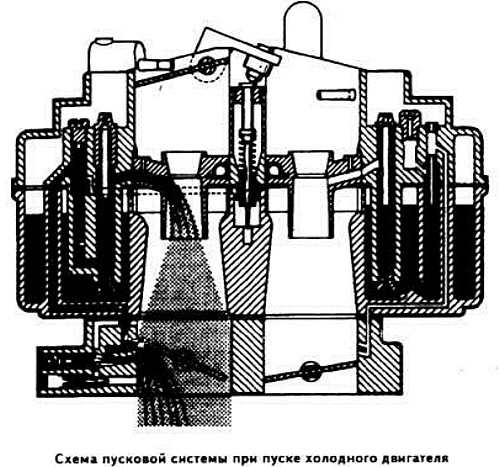

1st phase of the automatic starter (cold start)

At the moment of starting the engine, the controller processes the signals from the temperature sensors, the angular position of the throttle valve of the 1st chamber and the reference point (engine speed), and outputs control signals to the servomotors of the air damper and throttle damper of the 1st chamber.

The air damper is closed depending on the temperature. Under the action of the vacuum created in the space under the air damper, the air-fuel emulsion is sucked through the main fuel jet, the idle fuel jet and the transition system. The degree of opening of the air damper, which has an offset axis, is regulated under the action of vacuum depending on the engine speed.

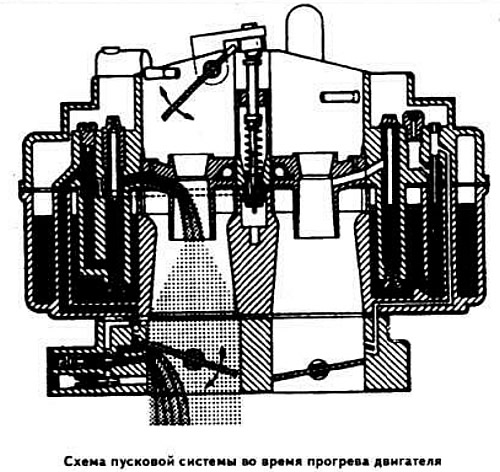

2nd phase of the automatic starter (engine warm-up)

After starting the engine, in order to lean the combustible mixture, the controller issues a command to reduce the moment of closing the air damper servo, which opens slightly at the appropriate angle. To prevent an excessive increase in the number of engine revolutions after starting, the controller issues a control signal to the throttle valve servo drive of the 1st chamber, which turns 8 to the closing side.

At idle and at modes close to idle, at medium coolant temperatures, the composition of the fuel-air mixture is controlled by moving the needle of the idle air jet depending on the position of the air damper.

Idle system and transition system of the 1st chamber

After the engine warms up, the air damper is open and the enrichment of the combustible mixture stops. Based on the information about the engine speed, the controller issues a control signal to the throttle servo of the 1st chamber, which is completely closed. The idle system of the 2BE carburetor operates in the same way as conventional carburetors. The fuel-air emulsion enters the transitional system of the 1st chamber through the transitional slotted channel before switching on the main dosing system.

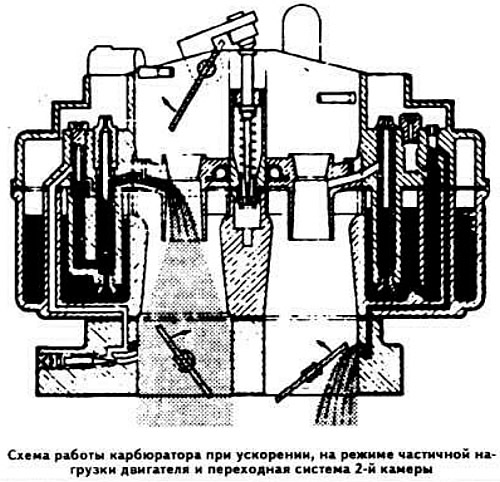

Acceleration

When the engine speed increases, the controller solves the problem of adapting the amount of fuel supplied to the carburetor with the growing amount of incoming air, i.e. when preparing the fuel-air mixture, it is necessary to compensate for the amount of fuel that condenses on the walls of the carburetor due to an increase in vacuum in the intake manifold.

In the 1st chamber, a pressure drop is created, the magnitude of which depends on the duration and moment of closing. applied to the air damper by a servo drive according to the controller commands. As a result, the amount of fuel entering the main metering system through the main fuel jet increases. The degree of enrichment of the combustible mixture during acceleration depends on temperature, engine speed, position and opening speed of the throttle valve of the 1st chamber.

There is no accelerator pump in the design of the 2BE carburetor.

Partial load mode

At partial engine load, the main dosing system of the 1st chamber is switched on. The movement of the air damper to enrich the combustible mixture is carried out according to the program embedded in the controller, depending on the position of the throttle valve of the 1st chamber, which in turn depends on the number of revolutions and engine load.

Transition system 2nd chamber

The throttle valve of the 2nd chamber is moved under the action of a pneumatic drive, and the degree of its opening is determined by the opening angle of the throttle valve of the 1st chamber and the amount of intake air. The lever system of a special design ensures smooth opening of the throttle valve of the 2nd chamber, depending on the position of the lock lever, only after the throttle valve of the 1st chamber has opened 2/3 of the full flow area. To prevent damage to the carburetor elements, the throttle valve returns to its original state during the closing of the throttle valve of the 1st chamber. At the moment the throttle valve of the 2nd chamber begins to open, the transition system compensates for the inclusion of the main dosing system. When the accelerator pedal is depressed so that the throttle valve is open more than 2/3, the throttle valve of the 2nd chamber opens. This causes a partial closing of the air damper on the commands of the controller. Instant enrichment of the combustible mixture provides a smooth transition to the operation of the 2nd chamber in power modes.

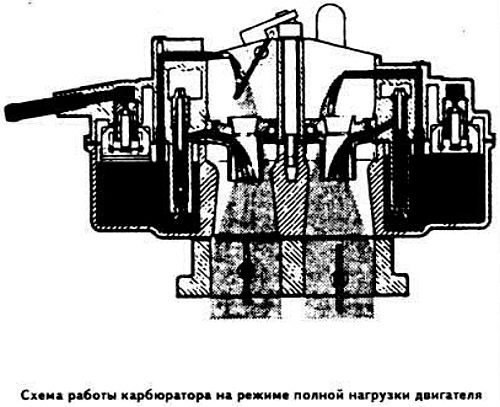

At full engine load, the degree of opening of the throttle valve of the 2nd chamber is determined only by the amount of intake air, which in turn depends on the engine speed. The opening speed of the throttle valve of the 2nd chamber is determined by the flow area of the damper nozzle installed in the intake manifold and controlled by a thermostatic valve.

Engine full load mode

At full load and starting from intermediate engine modes, the main dosing systems and economizers of the power modes of the 1st and 2nd chambers are switched on. The power mode economizer tubes are located in a vacuum zone located higher than the emulsion tubes of the main dosing systems. As a result, power mode economizers are switched on only when there is a significant air flow.

Forced idle mode and engine stop

With a decrease in the speed of the crankshaft, the throttle valve of the 1st chamber closes under the action of a servo. At engine speeds above 1400 rpm, the fuel supply is interrupted. In this case, the emulsion exit hole from the idle system is located above the edge of the throttle valve of the 1st chamber, i.e. in the atmospheric pressure zone, and the idle system is turned off.

When the ignition is turned off, the fuel supply stops, which makes it impossible to continue the rotation of the engine crankshaft. At the same time, when the throttle valve of the 1st chamber is closed, under the action of vacuum in the intake manifold, the air valve of the engine braking system opens, which limits the vacuum in the intake manifold during engine braking at high speeds.

After opening this valve, the interior of the air filter communicates with the intake manifold. Such a purge contributes to the afterburning of unburned gases in the exhaust tract.