2. Clean the drive shaft and clamp it in a vise.

Telescopic drive shaft

3. On some models, the inner CV joint is mounted on a short shaft that can move inside the drive shaft. Remove the two inner joint boot clamps, then remove the boot from the joint.

4. Mark the relative position of the CV joint shaft and the drive shaft, then remove the CV joint shaft from the drive shaft (pic. 5.4).

5. Remove the two collars of the outer pivot boot and remove both boots from the inner end of the input shaft.

Other drive shafts

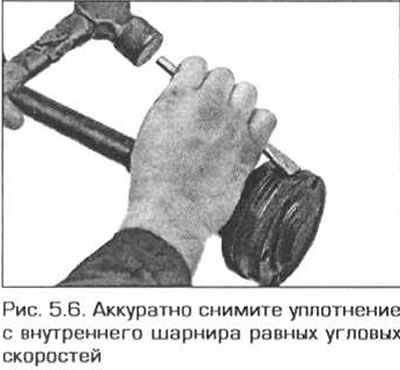

6. Remove the sealing cap from the inner CV joint (pic. 5.6).

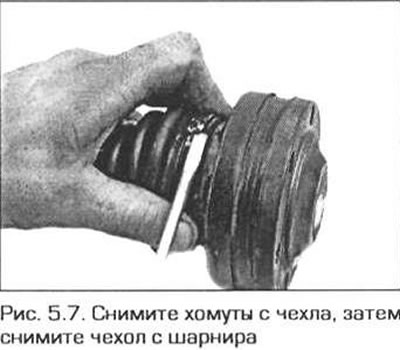

7. Remove two collars from a cover of the internal hinge and slide a cover and anther from the hinge on a shaft (pic. 5.7).

8. Remove grease, then remove the inner pivot retaining ring (pic. 5.8).

9. Fasten the hinge components securely, then remove it from the drive shaft (pic. 5.9). If the hinge cannot be removed, use a suitable puller. Do not disassemble the hinge.

10. After removing the hinge, remove the cover and boot from the drive shaft (pic. 5.10).

11. Remove the clamps from the outer pivot boot, then remove the boot from the inner end of the input shaft.

All drive shafts

12. Rinse hinges thoroughly in kerosene or other suitable solvent and dry. Inspect the hinges as follows.

13. Rock the inner link and watch the balls. The balls must not show signs of wear or damage.

14. Inspect the tracks of the balls. Tracks should not show signs of wear. Examine the separator windows. Windows must not be damaged or worn.

15. If any of the components is worn or damaged, it must be replaced. The inner joint can be replaced separately, however, if the outer joint is defective, the drive shaft assembly must be replaced. If the hinges are in good condition, purchase a repair kit that contains boots, clamps, an inner hinge retaining ring, and the required amount of lubricant.

Telescopic drive shaft

16. Put new boots on the inner end of the input shaft. Note that the outer hinge boot is 55 mm long and the inner hinge boot is 65 mm long.

17. Fill both hinges with the grease provided in the repair kit.

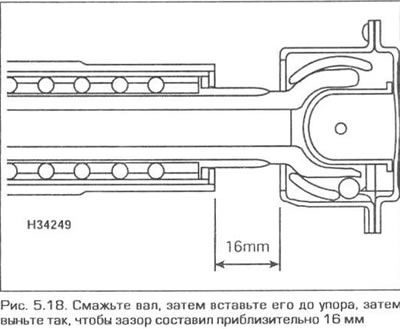

18. Lubricate the splines of the inner joint shaft. Align the marks made earlier, insert the inner joint shaft into the drive shaft until it stops, then remove it like this. so that the end of the hinge is at a certain distance from the drive shaft (pic. 5.18).

19. Put the covers on the hinges so that their edges take the desired position on the shaft and on the hinges. Raise the outer edges of the covers to equalize the air pressure inside the covers.

20. Put the clamps on the inner hinge cover so that their locks are located on the same line with the rivet on the flange. Tighten the clamps.

21. Put the clamps on the outer hinge cover so that their locks are rotated 180°relative to the locks of the inner hinge boot.

Other drive shafts

22. Tape the splines of the input shaft.

23. Put on a new cover of an external hinge on a leading shaft.

24. Fill the outer joint with grease from the repair kit. At the same time, shake the hinge so that the lubricant gets inside it. Put the rest of the grease inside the cover.

25. Put on the cover and make sure that its edges are in the right places. Pry up the outer edge of the case to equalize the air pressure inside the case.

26. Put a large metal clamp on the case, tighten it. then fold back and cut off the excess. Tighten the smaller diameter clamp in the same way.

27. Put on the inner joint cover on the boot, then put them on the drive shaft.

28. Remove the tape from the splines of the input shaft and put on the inner hinge. Slide the joint onto the drive shaft until it stops and secure with a circlip.

29. Completely fill the inner joint and boot with grease (pic. 5.29 a. b).

30. Put on the cover, then put the boot on the hinge. Make sure the mounting bolt holes are aligned. Pry up the outer edge of the boot to equalize air pressure, then secure the boot with zip ties (see point 26).

31. Apply some sealant and put a new sealing cap on the inner hinge.

All drive shafts

32. Check that both joints turn smoothly and easily, then install the drive shaft on the vehicle (see paragraph 4).