General information

1. Proper spark plug performance is vital to engine performance and power output. Obviously the spark plugs need to match the engine (the recommended type of candles is indicated at the beginning of this chapter). If this type of spark plug is used and the engine is in good condition, the spark plugs do not require attention until they are scheduled to be replaced. Spark plug cleaning is rarely required. You should not start cleaning candles without special tools, because without such tools the candle is easily damaged.

M43TU engine

2. Candles are located on the right side of the cylinder head.

3. For easier access to the spark plugs, remove the ignition coil mounting bolts and move the coil to the side (if necessary, contact for details chapter 5B).

4. If the high-voltage wires are not numbered, mark them yourself with numbers from 1 to 4 in accordance with the cylinder numbers (Cylinder numbering starts at the timing chain side). Pull the tips of the high-voltage wires from the candles. Do not pull on the wire, pull only on the rubber insulator (pic. 19.4).

5. Before turning out the candles, clean their nests of dirt with a brush, vacuum cleaner or compressed air so that this dirt does not get into the cylinders.

6. Unscrew the spark plugs with a special spark plug wrench or a high socket wrench (pic. 19.6). When removing the spark plug, hold the key straight, otherwise the ceramic insulator may be damaged. When all the candles are turned out, inspect them as follows.

7. Inspection of candles allows you to learn a lot about the condition of the engine. If the tip of the insulator is clean and white, without any plaque. means the engine is running lean, or the spark plug is overheating (a hot candle transfers heat from the electrodes worse than a cold one).

8. If the tip of the insulator is covered with black deposits, then the mixture was too rich. If black deposits have an oily appearance, then the engine is also worn out.

9. If the tip of the insulator is covered with gray or brown scum, then the mixture has a normal composition, and the engine is most likely in good condition.

10. When buying new spark plugs, it's important that they match your car's type.

11. If the candle has several electrodes, then the gap between the central and each of the side electrodes cannot be adjusted. If there is only one side electrode, then the spark plug gap can be adjusted. If the gap is too large or too small, then the length and power of the spark may not be sufficient to reliably ignite the mixture. The gap should be adjusted according to the manufacturer's recommendations (pic. 19.11).

12. To adjust the gap in a spark plug with one ground electrode, first measure it (pic. 19.12). Then bend the side electrode until the required gap is reached. Never bend the central electrode - in this case, the insulator will almost inevitably crack and the candle can be thrown away. When using a flat feeler gauge, the clearance is considered to be properly adjusted if the feeler gauge passes through it with some friction.

13. You can use a special tool to adjust the gaps of the candles. Such a tool can be purchased at related stores.

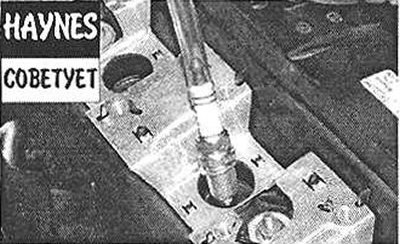

14. Before installing new spark plugs into the engine, make sure that the threaded ends on the outer ends of the spark plugs are securely tightened. Clean the outer surfaces of the spark plug, including its threads, from dirt and protective grease. Sometimes it can be difficult to start screwing in the spark plug so that the threads of the spark plug fit into the threaded hole in the cylinder head without distortion. In order not to damage the threads, put a piece of hose of a suitable diameter on the outer insulator of the spark plug (see Haynes advises).

It is often difficult to screw in a spark plug without tilting it. To avoid the undesirable consequences of such a distortion, put a piece of rubber or plastic hose with an internal diameter of 8 mm on the insulator. The flexible hose works like a universal joint, helping to guide the spark plug threads into the threaded hole. If the threads are skewed, the hose will simply slip along the candle body and will not allow the threads to be stripped.

15. Remove the rubber tube (if you have used it) and tighten the spark plug with a torque wrench, setting it to the torque specified in the Technical Data. Do the same with the rest of the candles.

16. Connect the high-voltage wires to the spark plugs and reinstall the ignition coil (if it was removed).

N42 engine

17. The spark plugs are located under the ignition coils on the right side of the cylinder head.

18. Remove the ignition coils as indicated in chapter 5B.

19. Follow the steps indicated in p.p. 5-15 of this paragraph.

20. Reinstall the ignition coils.

6 cylinder engine

21. Candles are located under the ignition coils in the center of the cylinder head.

22. Remove the ignition coils as directed in chapter 5B.

23. Remove dirt from the ignition coil seats with a brush, vacuum cleaner or compressed air so that this dirt does not get into the cylinders.

24. Unscrew the candles with a special candle wrench, or a socket wrench with a high head (see fig. 19.8). Do not twist the key so as not to break the spark plug insulator.

25. Follow the steps described in p.p. 7-15 of this paragraph.

26. Replace the ignition coils (see chapter 5B).