Attention! Always change pads on both front brakes at the same time. Replacing pads on only one of the wheels can lead to uneven braking. Dust generated during pad wear may contain asbestos, which is very hazardous to health. Do not blow off dust with compressed air and do not inhale air containing asbestos. Use a respirator when working on the brakes. Don't use gasoline (or gasoline-based solvents) for dust cleaning. Use brake fluid or methyl alcohol.

1. Apply the parking brake, then raise the front of the car and place it on stands (cm. "Lifting and placing the car on supports"). Remove the front wheels.

2. Using a screwdriver, carefully unhook the anti-noise spring from the side wall of the caliper, remembering its location (pic. 4.2, a, b).

3. Remove the wear sensor from the pad (if it exists), then remove it from the caliper hole (pic. 4.3, a, b).

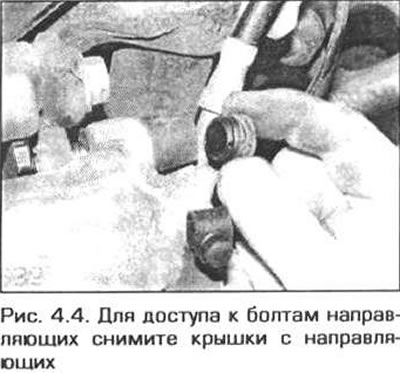

4. To access the guide bolts, remove the plastic covers from the caliper guides (pic. 4.4).

5. Using a hex wrench, loosen the tightening and remove the guide bolts. Remove the caliper from the bracket and secure it to the suspension strut with a piece of wire (pic. 4.5, a-c). Do not allow tension on the caliper hose.

6. Disconnect the inner pad from the piston, then remove the outer pad from the caliper bracket (pic. 4.6, a, b).

7. First of all, measure the lining thickness of each pad (pic. 4.7). If in any place the thickness of any of the pads has a limit value (or below it), then you need to replace all four pads. The pads should also be replaced if any of them are oily, as there is no reliable way to remove such contamination from the friction material. If one of the pads is unevenly worn or contaminated with oil, the cause of this must be identified and eliminated before starting the assembly.

If the pads are in satisfactory condition, clean them thoroughly with a soft brush (or something similar), not forgetting the sides and back of the metal base. Clean the grooves on the lining surface (if they exist) and remove large particles of dirt or wear products that have penetrated into the material. Thoroughly clean the pad mounting locations in the caliper and support bracket.

9. Before installing the pads, make sure that the guide pins are tight enough to slide freely in the caliper bracket. Brush off dust and dirt from the caliper and piston. Do not inhale the dust - it is hazardous to health. Inspect the piston dust seal for damage and the piston for leaks, corrosion, or damage. If any of these components require attention, please contact paragraph 8.

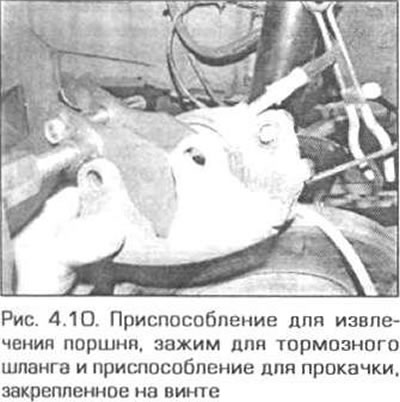

10. If you are installing new brake pads, the caliper piston must be pressed into the cylinder to provide space for the pads. Use a clamp or a wooden block as a lever for this. Clamp the caliper brake hose and connect the brake bleed kit to the bleed screw. After that, unscrew the bleeder screw and press the piston into the cylinder. The brake fluid displaced by this will collect in the reservoir of the bleed kit (pic. 4.10). Before. once you have finished pushing the piston in, tighten the bleed screw. These measures will prevent air from entering the brake system.

Note. ABS systems are very sensitive to the presence of dirt in the brake fluid. Even small particles of dirt can cause clogging of the system. The method described above for sinking the piston. avoids the risk of contamination of the system and damage to the seals of the master cylinder.

11. Apply brake grease to the back of each pad. Do not apply too much lubricant or allow it to come into contact with the friction material.

12. Insert the outer pad into the caliper bracket with the working side facing the brake disc (pic. 4.12).

13. Install the inner pad on the piston, then install the caliper in place (pic. 4.13).

14. Screw in bolts of fastening of directing fingers and tighten them the demanded moment. Put the covers on the rails.

15. Install a wear sensor on the outer shoe. Make sure. that its wiring is routed correctly (see fig. 4.3, a, b).

16. Attach the anti-noise spring to the caliper (pic. 4.16). Press the brake pedal several times to bring the pads to the disc and restore the brake pedal stroke.

17. Repeat the above procedure for the other front brake.

New pads do not provide maximum braking performance until they are worn in. With this in mind, if possible, avoid sudden braking for several hundred kilometers after replacing the pads.