To check the compression of a diesel engine, a special compression gauge is required, which is screwed into the threaded hole of the glow plugs. The diesel engine compression test is not described here.

The difference between the compression pressures of the individual cylinders must not exceed 1.0 bar for a petrol engine and 3.0 bar for a diesel engine.

If one or more cylinders have a higher pressure than the others, this indicates damaged valves, worn piston rings, or damaged cylinder head gaskets. In this case, the engine must be repaired or replaced.

The pressure value is of secondary importance, since it depends, among other things, on the measuring device used. For gasoline engines, it should not be less than 10 bar.

Examination

1. Test condition is a charged battery.

2. Turn off the ignition.

3. Disconnect the main relay of the electronic control system of the engine to exclude fuel injection during the test. The location of the control system relay is shown in the Specifications Chapter Onboard electrical equipment.

If the engine control system relay does not disconnect, the main control system relay output stage may be damaged.

4. Remove all spark plugs, refer to Section Checking fluid levels.

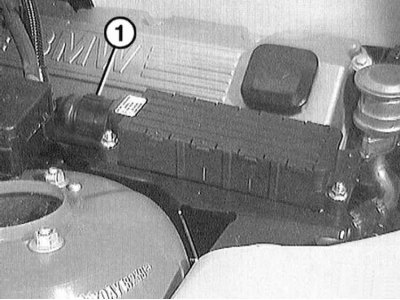

5. Models 316i, 318i: Disconnect the multi-pole connector of the ignition coils, for which turn the handle -1- to the left.

6. Set the manual transmission to neutral, automatic to "R". Apply the parking brake.

Do not lean over the engine if it is cranking with the spark plugs removed. There is a risk of injury due to soot particles escaping!

7. Insert or screw the compression tester into the spark plug hole according to the instruction manual.

8. Ask an assistant to fully depress the gas pedal and hold it in this position during the entire test.

9. Turn the engine about 8 revolutions so that the increase in pressure on the compression gauge stops.

10. Thus, sequentially check all cylinders.

11. If the compression in one or more cylinders is below the wear limit, pour in some engine oil through the spark plug hole and measure the pressure again with a compression gauge. If the pressure then rises, this indicates wear on the piston rings and/or cylinder sliding surface. If the pressure does not rise, then the valve or cylinder head gasket is usually damaged

12. Install spark plugs, refer to Section Checking fluid levels.

13. Models 316i, 318i: Mate the multi-pole connector of the ignition coils while turning the knob to the right.

14. Install the main relay of the engine control system, refer to the Specifications of the Chapter Onboard electrical equipment.