Withdrawal

Loosen the wheel bolts with the vehicle on the ground.

Mark with paint the relative position of the disk and the wheel hub in order to subsequently install the balanced wheel in its original place.

Raise the car and remove the wheel.

Screw in wheel bolt and secure to wheel bolt and coil spring, see illustration. With such a suspension, the hub will not fall after unscrewing the bolts.

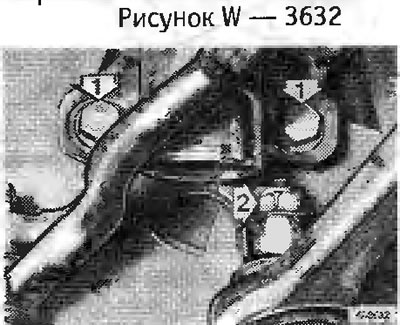

Loosen the bolt -2- of the ball joint until it rests on the suspension strut.

Loosen lower bolts -1- for suspension strut. Clean threaded holes with a wire brush.

Loosen centering bolt -2-, while marking the position of the washers (at both sides) for their subsequent installation.

Press the ball joint with a suitable puller, e.g. HAZET 779.

Remove screws -1- from bottom.

From the upper side, unscrew the ball joint nut -2- on the axle beam. Knock out the ball joint with a plastic hammer. Remove transverse link.

Installation

Thoroughly clean and degrease the ball bearing journals and corresponding bores with solvent before installing the control arm.

Be sure to replace self-locking nuts.

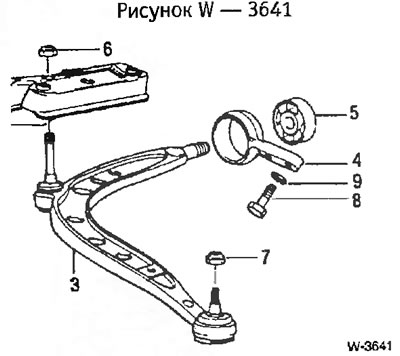

Insert transverse link. To install the nut -6- on the front axle beam, press the transverse lever upwards from the ball joint with a jack. In this case, use a wooden gasket.

Tighten bolts -8- and new self-locking nut -6- to 50 Nm.

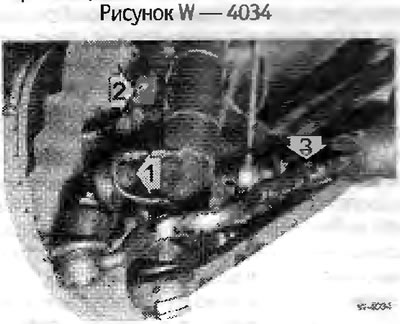

Insert the centering bolt -2- from below, observing the correct installation position of the washers (Drawing W 4034). Screw on a new self-locking nut and tighten it to 110 Nm. (Drawing W 3632) Screw the suspension strut on from below with new bolts to a tightening torque of 110 Nm. The bolts have a locking coating and must be replaced after each loosening.

Tighten a new self-locking nut -7- on the outer ball joint of the control arm to a torque of 65 Nm (Drawing W 3641). Remove wire hanger.

Screw on the wheel, observing the markings made during removal. Lower vehicle and tighten wheel bolts crosswise to 110 Nm.