Withdrawal

Attention: If the valve actuator parts are to be installed again, they must be installed in their original positions. To do this, when removing them, they must be folded in the order of installation.

Remove cylinder head.

Remove camshaft.

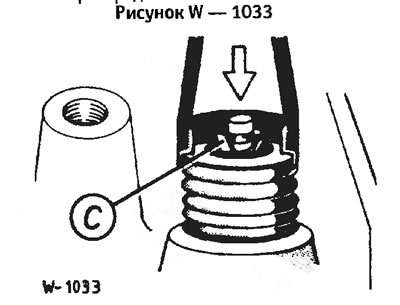

Compress the valve springs and remove the cotters -C-. You can use a conventional valve presser to compress the springs. Depending on the tool used, it may be necessary to remove the exhaust manifold.

Unload the springs and remove the upper spring cup, valve spring, and lower spring cup.

Remove the oil seals with a special tool. The 791-5 flinger pliers or the 791-2 inertial puller from HAZET are best suited for this.

Pull the valve out of the cylinder head towards the combustion chamber.

Remove the next valve.

Installation

Before installing the valves, check the valve guides, it is possible to grind the valve seats.

Attention: When installing a new valve, lapping of the valve seat is mandatory.

Remove burrs from the contact surface of the valve stem with crackers.

Lightly coat the valve stem and guide with engine oil, and insert the valve.

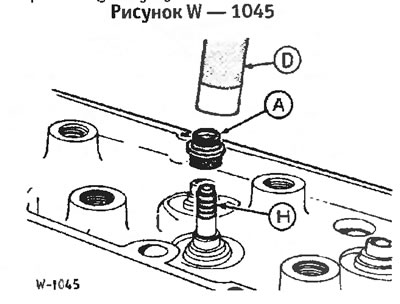

Lightly lubricate with engine oil and fit flinger -A- using appropriate tool -D- or stop.

Caution: To prevent damage to the oil flinger, put mounting sleeve -H- on the valve stem before installing it. If there is no mounting sleeve, cover the contact surfaces of the valve cotters with smooth adhesive tape. After installing the sticky, remove the tape.

Insert the lower valve spring cup.

Insert spring and upper valve spring cup.

Caution: If the spring is damaged, both valve springs must be replaced (inner and outer spring). Install springs only with the same manufacturer's markings, the same wire thickness and spring length.

Insert the top valve spring cup.

Compress the valve spring and insert crackers. Slowly unload the valve spring, while ensuring the correct seating of the cotters.

Then install the next valve. At the same time, do not interchange the intake and exhaust valves.

Install the cylinder head.

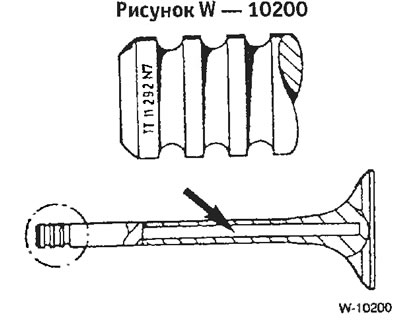

Attention: The exhaust valves of the 4 cylinder engine are filled with sodium to improve heat dissipation. They should not burn through and be used as a tool (like punches). Explosive! Also, these valves should not just be thrown away. To dispose of them, cut the valves with a hacksaw in the middle of the valve stem into 2 parts. At the same time, do not allow the valve to come into contact with water and then discard it.

Caution: When sodium comes into contact with water, a rapid chemical reaction occurs, during which the sodium burns out. Therefore, step aside and protect your eyes.