Since some of the connections under the vehicle also need to be removed, the vehicle must be lifted and placed on secure stands. Before assembly work in the engine compartment, the front fenders must be covered.

Electrical wires, as well as vacuum and water hoses, can be routed differently in the engine compartment depending on the year of manufacture and the composition of the equipment. Since it is impossible to give a detailed description of each of the routing options, I recommend that you mark the wires and hoses when they are disconnected.

Describes engine removal on models 316i, 318i (4and also on models 3201.325t (6-cylinder engines). Engines installed in the 316i, 318i models from September 1993 have changes associated with a new ignition system without a distributor and a modified intake pipe.

Withdrawal

Remove gearbox.

Raise the car.

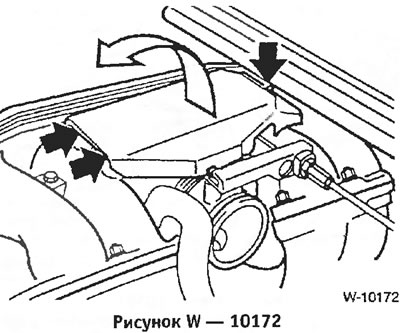

Place the engine compartment hood in the installation position, i.e. vertically. To do this, unhook -arrow- and press bonnet upwards. Press the hinge hinge and release the hood.

Attention: When the hood of the engine compartment is installed in the installation position, it is forbidden to turn on the wiper. The windshield wiper does not have freedom of movement and scratches the hood. It is recommended to pull out the wiper fuse.

Disconnect the ground wire from the battery.

Attention: When the battery is disconnected, the information in the electronic memory devices, such as the engine trouble memory or the radio security code memory, is erased. When disconnecting the battery, follow the instructions in sections "Radio" And "Removing and installing the battery".

Attention: On vehicles with six-cylinder engines, the battery is located in the luggage compartment next to the spare wheel.

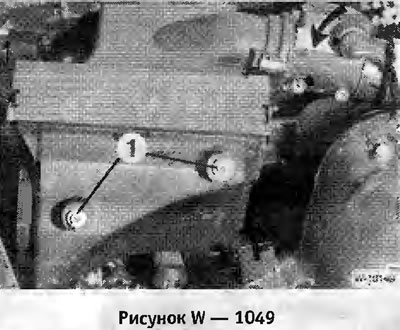

Remove the air filter and air mass meter. To do this, turn the knurled nut on the connector to the left and remove the connector. Unscrew bolts -1- and loosen hose clamp and pull out air filter box.

Six-cylinder engine: Unscrew the coolant/intake air thermostat and pull out the sensor

Disconnect the idle air control valve and crankcase breather hoses from the intake hose. Four-cylinder engine: remove the electrical wires from the intake hose.

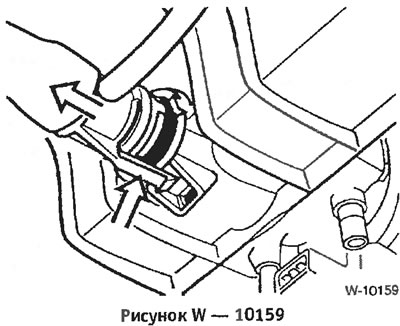

Six-cylinder engine: Unscrew alternator air duct -arrows- and pull out.

Drain coolant.

Remove radiator.

Attention: If the hoses are fastened with clamps, cut them off and install screw clamps during installation.

Four cylinder engine

Disconnect the water hoses from the thermostat housing, after releasing the hose clamps.

Disconnect the hose from the engine going to the expansion tank of the cooling system.

Remove the throttle lever cover. To do this, unscrew the bolt, lift the cover and unscrew the 2 front bolts.

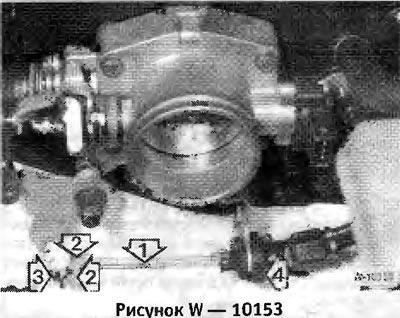

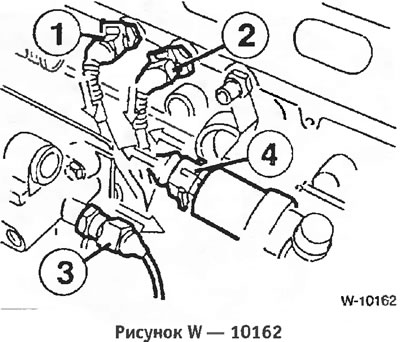

Disconnect the throttle cable -1-, to do this release the clip in the direction of the arrow. If equipped with automatic transmission, also disconnect cable -2-.

Unscrew bolts -3- and lay cables with fasteners to one side.

Disconnect connector -4- for idle speed regulator and vacuum hoses -5- and -6-.

Disconnect the water hoses from the heater tap and from the heater, after releasing the clamps.

Remove the heater fresh air intake duct.

Disconnect the vacuum hose from the brake booster. Removal requires force.

Attention: Close the opening on the hydraulic booster with a clean cloth.

Six-cylinder engine

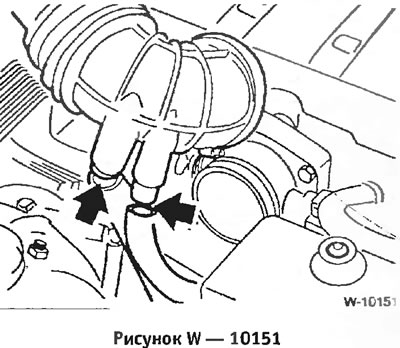

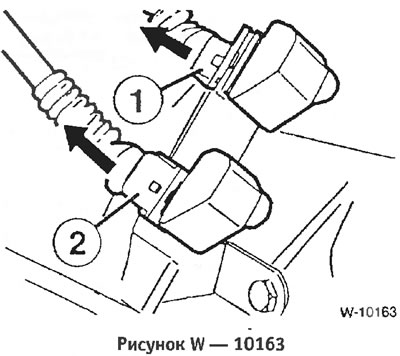

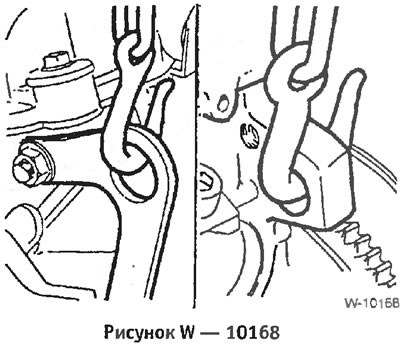

Detach throttle cable -1- from throttle lever. To do this, press the throttle lever in the direction of the cable, release the nipple -3- with a narrow screwdriver. Press tabs -2- on clips together and pull out of throttle lever. Pull the throttle cable down from the slot in the throttle lever. If present, remove the second cable in the same way (with a special composition of the equipment of the speed control system, see figure).

Remove the oil filler cap.

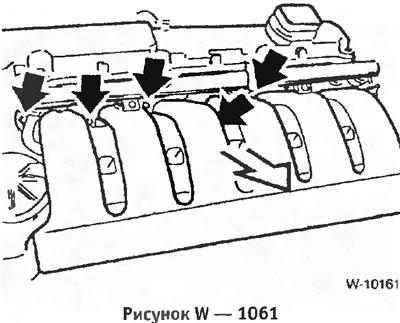

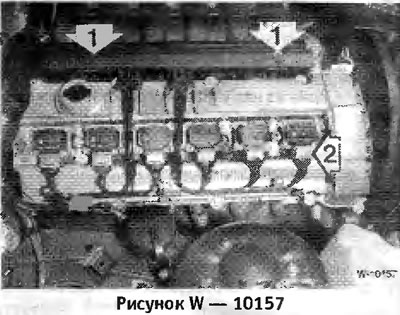

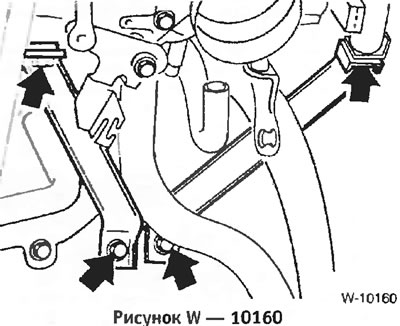

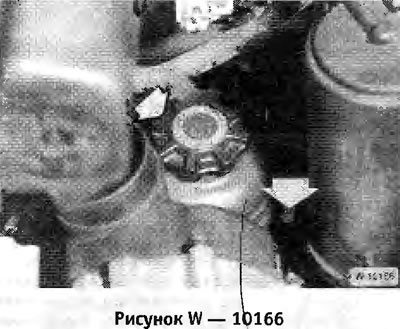

Lever out the small plugs -arrows- with a screwdriver and remove the bolts underneath. Remove 2 plastic trims from cylinder head.

Unscrew earth bar -1- from front of cylinder head.

Detach the breather fitting -2- from the cylinder head by lifting the tab on the fitting with a screwdriver.

Unscrew 2 bolts -1 and pull up the block with a connector. Note the position of the rubber pads for subsequent installation.

On each ignition coil, pull up the metal clip -2- and disconnect the connector, see illustration. Remove the connector block along with the wires.

Disconnect the following hoses and connectors from the throttle body. It is advisable to mark the hoses and wires and their connection points before disconnecting, so as not to confuse them during subsequent installation. Release the hose clamps, compress the fixing brackets of the connectors. -1- throttle switch connector, -2- air temperature sensor connector, -3- throttle body heater water hoses, -4- fuel tank vent hose, -6- fuel feed hose (white fitting), -7- fuel return hose (black fitting).

Caution: Fire hazard, do not smoke. Wipe up leaking fuel with a cloth.

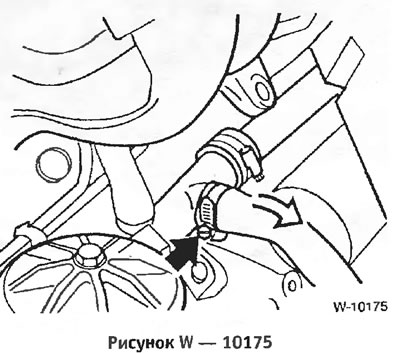

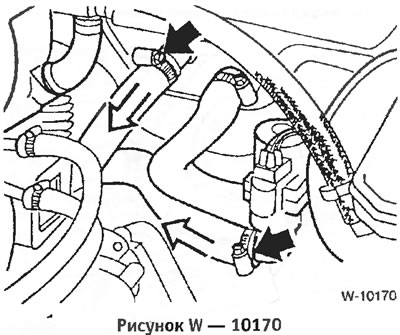

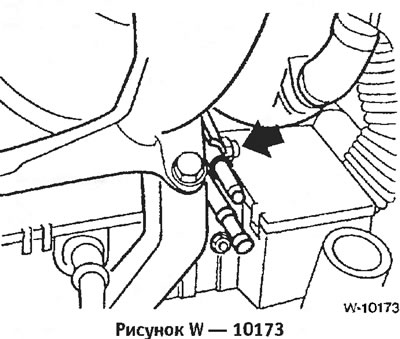

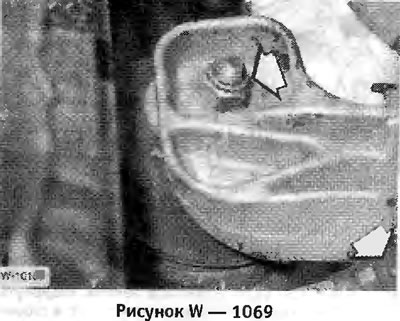

Six-cylinder engine: Disconnect the idle air control valve hose from the underside of the intake pipe. Caution: The locking tabs break easily. The connection point is not visible from above, the figure shows the view of the inlet pipe from below.

Four cylinder engine

Six-cylinder engine

Unbolt intake pipe support.

Unbolt intake manifold from cylinder head.

Caution: Do not allow any objects to enter the inlet. Objects not removed can cause severe engine damage.

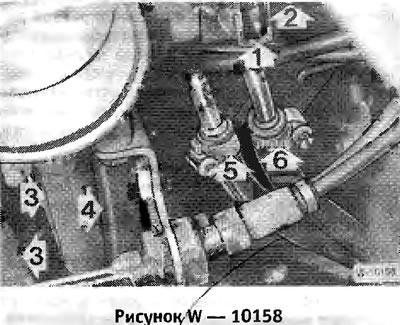

While pressing the wire clamps, disconnect the connectors. -1- temperature sensor, -2- temperature gauge sensor, -3- oil pressure switch, -4- idle speed control valve.

- On a four-cylinder engine, additionally disconnect the following connectors: ignition wires from the ignition coil, detachable injector connections (at the end of the cable channel), tank vent valve plug connection (in the line between the activated carbon tank and the inlet pipe).

Four-cylinder engine: Unscrew bracket for fuel hoses.

Disconnect the connectors on the flywheel housing: -1 - cylinder identification sensor (black); -2- pulse sensor DME (Motronic, gray).

Disconnect the alternator and starter wires.

Unscrew the cable duct from the engine block and set the engine wiring harness aside.

Four cylinder engine

Six-cylinder engine

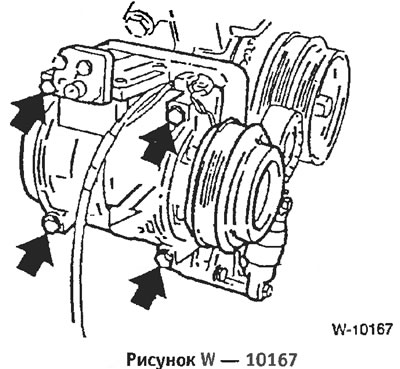

Vehicles with power steering: Remove the V-belt, unscrew the power steering pump and lay it aside with the hoses connected.

Caution: If the hydraulic system opens, it will need to be vented after installation.

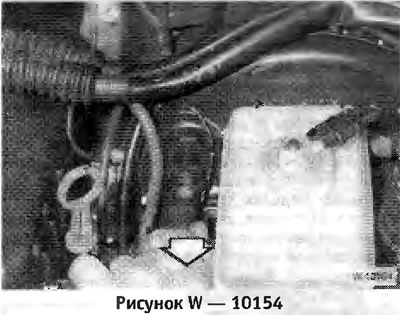

Unscrew the 2 bolts of the fixed power steering reservoir on the left engine support beam and hang the reservoir on the wire.

Vehicles equipped with air conditioning: Unscrew the air conditioning compressor and lay it aside with the hoses connected. Attention: Do not open the air conditioning circuit under any circumstances, as the release of freon can cause frostbite.

Hook up the engine with a rope. To do this, attach a rope or chain to the lifting eyes -arrow- of the engine. Raise the engine slightly with a crane.

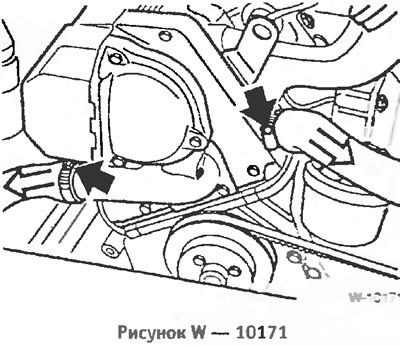

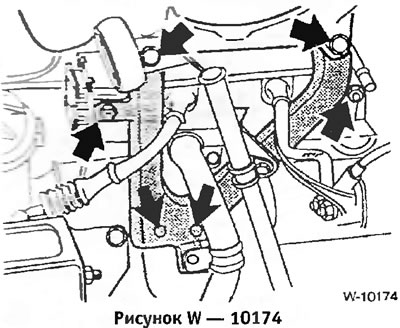

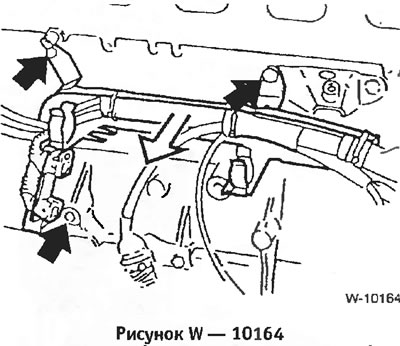

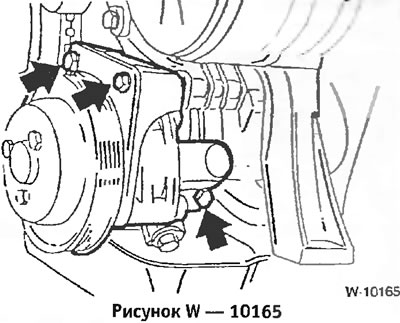

Unscrew nuts on right engine mount and earth strap -arrows.

Loosen the nuts on the left engine mount in the same way.

Check that all hoses and wires connecting the engine to the body are disconnected, and then pull the engine out

Attention: To avoid damage to the bodywork, drive the engine carefully.

The removed engine must not be left upside down for more than 10 minutes, as the hydraulic valve clearance adjusters will be emptied and become inoperable. If it is necessary to turn the engine over, remove the hydraulic valve clearance adjusters.

Installation

Check engine mounts, water, oil and fuel hoses for ruptures and cracks and replace if necessary.

Check the ease of rotation of the crankshaft bearing and clutch release bearing and the ease of movement of the clutch release fork.

Check the thickness and condition of the clutch disc friction lining.

Carefully guide the engine into the engine compartment. To avoid damage to the drive shaft, clutch and body, use the engine very carefully when lowering.

Screw, without tightening, the nuts of the engine mounts.

Raise the car.

Install gearbox.

Lower the car.

Pulling on the engine, align it. Then tighten the engine mounts to 45 Nm.

If removed, install A/C compressor.

Screw on the power steering pump.

Install and tighten the V-belt.

Connect the connectors of the cylinder recognition sensor and the DME encoder on the flywheel housing. Connect the connectors of the temperature sensor, temperature gauge sensor, oil pressure switch and idle air control valve.

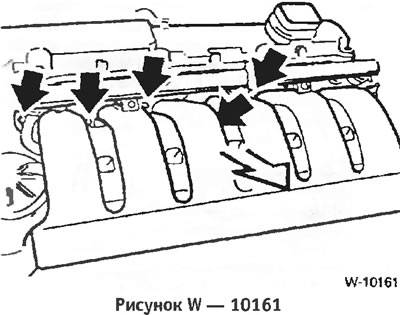

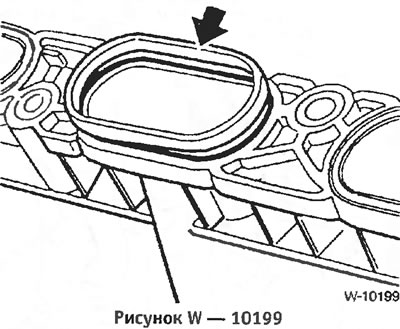

Six-cylinder engine: Insert intake pipe into cylinder head and screw down. Replace all gaskets -arrows- before installing.

Screw on intake pipe support.

Connect all electrical wires, vacuum, water and fuel hoses in accordance with the markings made during removal, to the throttle valve fitting, as well as to the cylinder head. Secure hoses with clamps. Fix electrical wires with cable clamps.

Install and screw the connector block on the cylinder head.

Fit and screw on the cylinder head cover.

Reconnect all removed connectors and hoses. Fasten hoses with clamps

Connect the throttle cable and, if equipped, the automatic transmission cable.

Connect the vacuum hose to the brake booster.

Insert and screw the heater fresh air supply duct.

Screw the electrical wires to the generator.

Screw on the generator cover.

Check the air filter element, knock it out or replace if necessary. Install the air filter.

Connect and secure the heater water hoses with clamps.

Install the radiator.

Install fan.

Check the frost protection properties of the coolant and, if necessary, add a concentrate.

Check the oil level in the engine and gearbox and top up if necessary.

Connect the wires to the battery.

Start the engine and warm up to operating temperature, check the coolant level and the tightness of all hose connections.

Install the protective tray of the power unit.