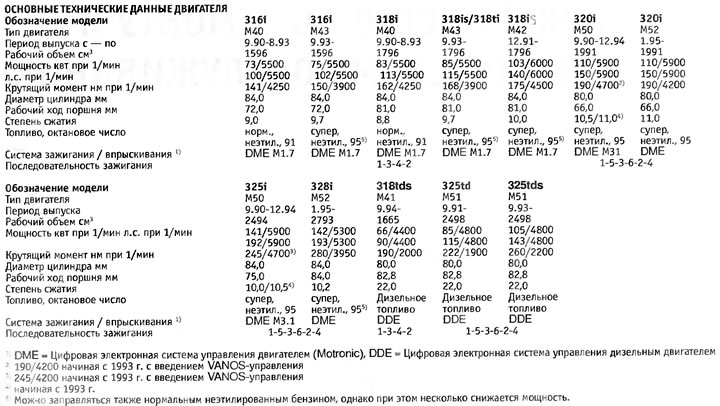

Depending on the model, the following power units are installed:

Model 316i/318ti:

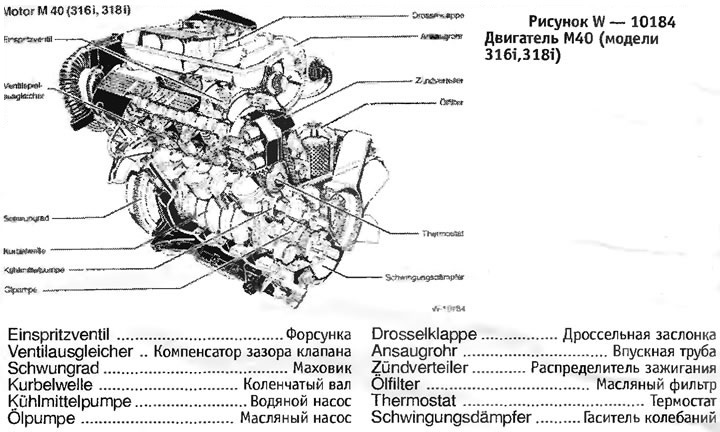

- 4-cylinder M40 engine with a displacement of 1.6 and 1.8 liters. Since September 1990, modified to the M43 engine (timing chain, ignition system, intake pipe).

Models 318i/318ti:

- 4-cylinder 4-valve M42 engine with a displacement of 1.8 liters.

Models 320i/325i:

- 6-cylinder 4-valve M50 engine with a displacement of 2.0 liters or 2.5 liters. Since January 1995, an aluminum cylinder block has been installed. Engine designation M52.

Model 318tds:

- 4-cylinder turbo diesel engine M41 with a displacement of 1.8 liters.

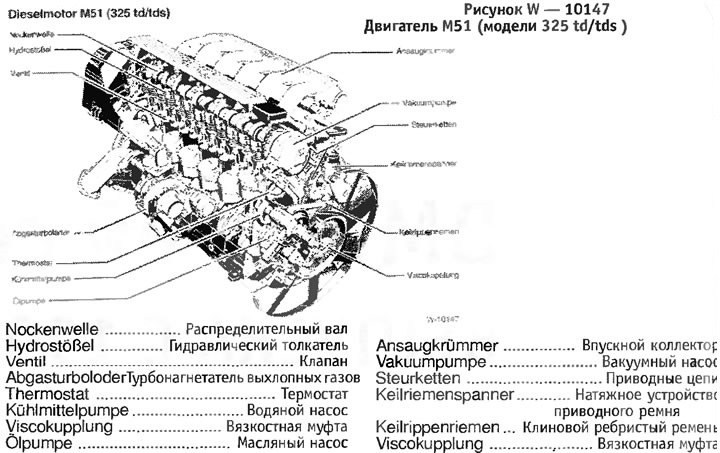

Models 325td/325tds:

- 6-cylinder M51 turbodiesel engine with a displacement of 2.5 liters.

The gray cast iron engine block has cylinder bores. With significant wear or scratches on the cylinder walls, the cylinders can be honed, that is, ground in a special workshop. After that, only oversized pistons should be installed. At the bottom of the engine block is a crankshaft mounted on its bearings. The connecting rods that communicate with the pistons are mounted on the crankshaft on plain bearings. The lower part of the engine is completed by the oil sump, which collects the oil needed to lubricate and cool the engine. On top of the engine block, a cylinder head made of light metal alloys is bolted. It is aluminum, since this metal, in comparison with cast iron, has a higher thermal conductivity and a lower specific gravity.

The cylinder head is built according to the so-called cross-flow principle. This means that the freshly prepared air-fuel mixture enters the cylinder head from one side, while the burnt gases are pushed out from the other side of the cylinder head. The cross flow design guarantees faster gas exchange. At the top of the cylinder head is the camshaft. The camshaft is driven on M40 engines from the crankshaft through a toothed belt. The camshaft controls the valves through rocker arms supported on the side opposite the valve by the valve clearance compensators. 4-valve gasoline engines have two camshafts, one of them controls the operation of the intake valves, and the other controls the exhaust valves. As with diesel engines, the camshaft is driven through a roller chain. The intake and exhaust valves are controlled by hydraulic tappets that require no maintenance. On all engines, valve clearance adjustment is not required as part of maintenance.

Since September 1992, the 6-cylinder petrol engines have been further developed, among other things, they are equipped with a variable camshaft control system, abbreviated as VANOS. In this case, with the help of an adjusting element, depending on the engine speed, the intake camshaft is rotated by a certain angle relative to the chain, as a result of which the optimum ignition moment is maintained. The setting element is controlled by the engine control unit. Other improvements have been to ensure the smoothest possible operation of the engine, torque characteristics, exhaust gas composition and fuel consumption: an increase in the compression ratio in conjunction with selective knock control, the installation of simple valve springs with low spring forces, lightweight pistons with extended connecting rods.

Engine lubrication is provided by an oil pump mounted on the 6-cylinder petrol engine at the front of the engine crankcase and driven through a chain drive. On 4-cylinder and diesel engines, the oil pump is located in the timing case cover and the end of the crankshaft and is connected to the last gear train. Oil from the oil sump enters through drillings and channels to the bearings of the crankshaft and camshaft, as well as to the working surfaces of the cylinders.

The water pump is located at the front of the engine block; its shaft at the appropriate temperature is connected by a viscous coupling to the radiator fan. The water pump is driven on 4-valve engines and on diesel engines through a V-belt, which also serves as a generator drive, and on the M40 engine through a camshaft toothed belt. It should be borne in mind that the cooling system must be filled with a mixture of antifreeze and anti-corrosion concentrate with lime-free water throughout the year

The ignitable air-fuel mixture is prepared by an electronic ignition and fuel injection device, which guarantees a stable composition of the exhaust gases.

On models 316i, 318i produced before August 1993, a so-called high voltage distributor is installed from the front of the cylinder head, instead of a conventional ignition distributor, which is driven directly from the camshaft. On all other gasoline engines, the ignition system does not have a distributor at all, that is, on these engines, there are no moving parts in the ignition system. On diesel engines, fuel metering is also controlled electronically using the DDE system (Digital Diesel Engine Management System).