Make sure that the blind holes in the cylinder block are clean, paying special attention to the absence of traces of oil on their bottom, since oil compression when tightening the cylinder head bolts can cause cracks in the cylinder block.

Apply Curil K2 type sealant to the mating surface of the timing cover.

Install the cylinder head gasket.

Place the camshaft in a position where the hole on its flange points downward and the groove on the flange aligns with the boss on the cylinder head.

In this case, the piston of the 1st cylinder should be at TDC of the end of the compression stroke, and the mark on the rim of the crankshaft pulley should be opposite the pointer on the bottom cover of the gas distribution mechanism.

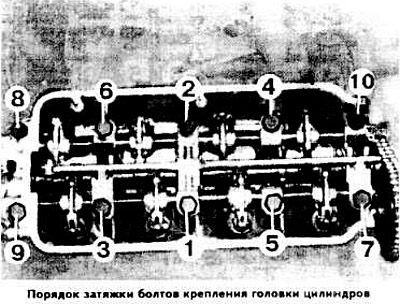

Install the cylinder head and tighten progressively in four steps in the order shown (bolt tightening torques, see subsection «Detailed Specifications»).

Slide the camshaft sprocket onto the flange of its flange, aligning the holes for the pulley mounting bolts on the pulley and flange. Tighten the camshaft pulley mounting bolts and lock them by bending the locking plates.

Install the plunger, spring and plug-plug of the tensioner of the drive target of the camshaft; at the same time, the plunger should go all the way into the body of the tensioner.

Adjust valve clearances.

Install the fuel pump, central oil line and ignition distributor.

Further installation of a head of cylinders is carried out in an order, the return to removal.